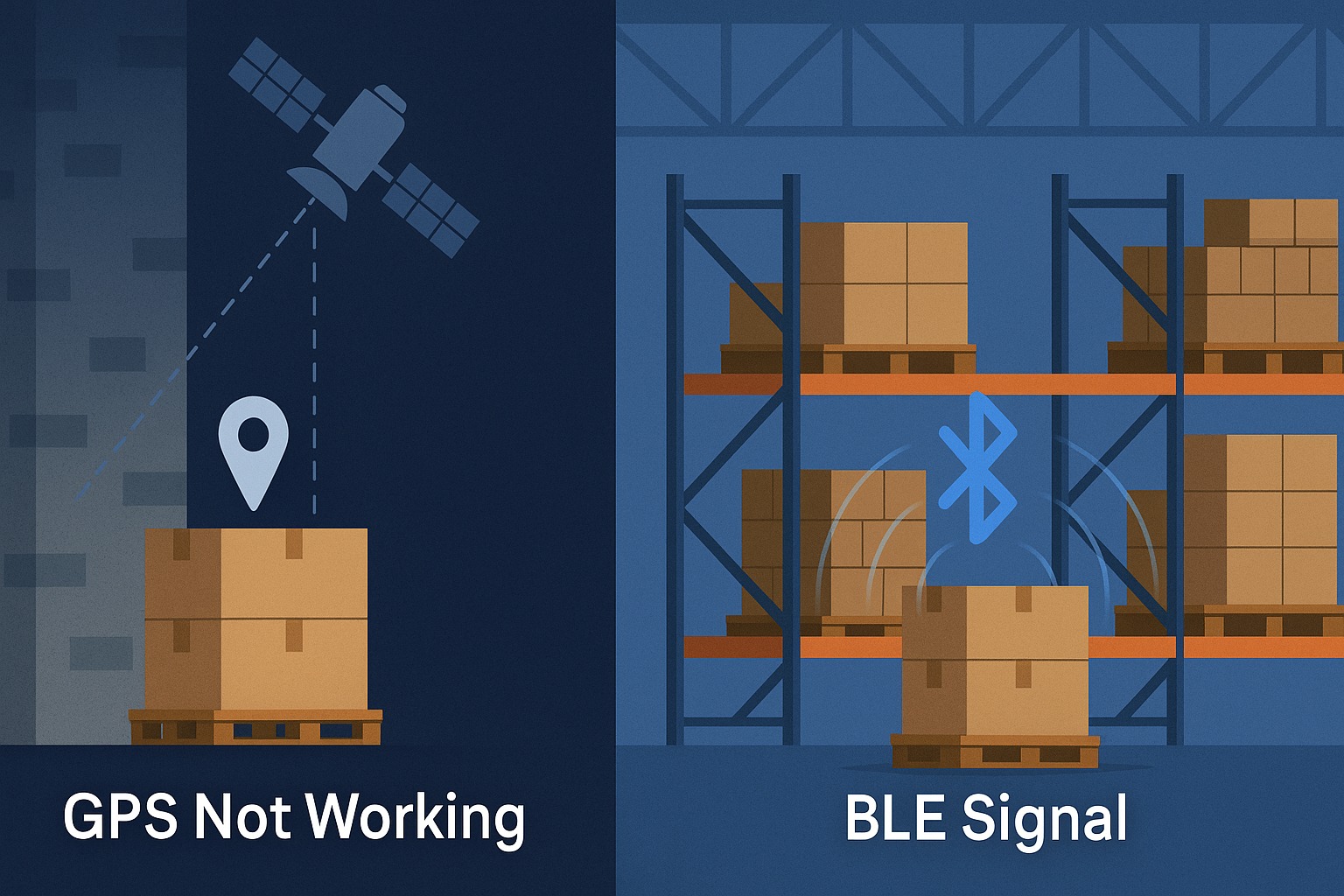

In modern manufacturing and warehousing, accurate pallet tracking is essential. Yet, GPS—the go-to for location tracking—fails indoors due to signal limitations. Concrete walls, steel structures, and enclosed spaces block satellite signals, making GPS unreliable inside warehouses. This is why BLE-powered smart pallet tracking systems are rapidly becoming the smarter, scalable alternative. Explore Smart Pallet Tracking Without GPS

- 1. The GPS Limitation Indoors

- 2. Introducing BLE-Based Smart Pallet Tracking

- 3. How BLE Tracking Works in Warehouses

- 4. The Cost Advantage of GPS-Free Tracking

- 5. AI and Edge Processing for Intelligent Tracking

- 6. Benefits for Non-Technical Stakeholders

- 7. Scalability and Customization Options

- 8. Testimonial: A Real Warehouse Transformation

- 9. Final Thoughts: GPS-Free Is the Future

1. The GPS Limitation Indoors

GPS relies on satellites to triangulate a device’s position. However, these signals degrade or vanish indoors. In warehouses, GPS suffers from multi-path interference, low precision, and complete blackouts in underground or densely constructed areas. This makes real-time indoor tracking of pallets nearly impossible with GPS alone.

2. Introducing BLE-Based Smart Pallet Tracking

Bluetooth Low Energy (BLE) solves the problem by enabling low-power, short-range communication between beacons and receivers. BLE tags attached to pallets continuously broadcast signals. Gateways or smartphones pick up these signals and calculate location using RSSI (Received Signal Strength Indicator) or angle of arrival (AoA). Unlike GPS, BLE thrives in indoor environments—offering accurate and consistent data even in signal-congested zones.

3. How BLE Tracking Works in Warehouses

Smart pallet tracking systems use BLE beacons, fixed gateways, and centralized cloud dashboards. As pallets move, the system updates their location in real-time. Edge devices forward beacon signals to the cloud via MQTT or REST APIs. Advanced software layers apply AI algorithms to filter noise, detect anomalies, and map movements onto warehouse layouts.

This real-time data enables teams to locate items instantly, optimize paths, and reduce delays during shipping and inventory audits.

4. The Cost Advantage of GPS-Free Tracking

BLE-based tracking systems are more cost-efficient and energy-efficient than GPS. BLE beacons last 2–4 years on coin-cell batteries, and the infrastructure requires less investment. There’s no need for cellular data or satellite subscription costs.

More importantly, BLE systems are modular and scalable, making them ideal for both small warehouses and multi-building industrial zones.

Want to explore indoor recovery use cases? Learn how BLE helps recover lost items in real-world settings

5. AI and Edge Processing for Intelligent Tracking

The smarter way to track pallets doesn’t stop at BLE. In 2025, AI and edge computing make BLE systems even more powerful.

Edge devices now process signals locally, reducing latency and cloud dependency. With machine learning algorithms, these systems can detect abnormal routes, idle pallets, or missing inventory before it becomes a problem. Data from BLE beacons is converted into actionable insights like zone heat maps, pick-and-pack optimization, and predictive maintenance alerts.

6. Benefits for Non-Technical Stakeholders

For warehouse managers and logistics teams, smart pallet tracking simplifies daily operations. The system offers:

- Real-time visibilityof all pallet movements

- Automated alertsfor unauthorized movements or misplacement

- User-friendly dashboardsfor non-technical staff

- Seamless integrationwith ERP and WMS platforms

With BLE, staff no longer need to scan barcodes manually or rely on guesswork during inventory checks. The system updates itself passively and reliably.

7. Scalability and Customization Options

Modern BLE tracking systems are highly flexible. You can start with a single zone and expand as needed. Tag types vary based on requirements: from ultra-thin paper tags for lightweight items to rugged industrial-grade beacons for heavy pallets.

APIs allow integration with mobile apps, dashboards, or even voice assistants. You can also set up geofencing zones for automation, like triggering alerts when a pallet enters a restricted area or exits the warehouse.

Explore BLE Tracking System Customization and Deployment

8. Testimonial: A Real Warehouse Transformation

“We replaced our outdated RFID and manual barcode system with BLE tracking powered by TheQTrace. Now we locate pallets in seconds—even in multi-story storage zones. Our inventory audit time dropped by 50%, and we’ve eliminated location-related errors entirely.”

— Logistics Manager, SmartLogi India Pvt. Ltd.

9. Final Thoughts: GPS-Free Is the Future

As indoor logistics operations grow more complex, relying on GPS is no longer practical or scalable. BLE-based pallet tracking provides the precision, cost-effectiveness, and intelligence that GPS cannot deliver indoors. With seamless integration, scalable design, and AI-ready architecture, BLE is powering next-generation warehouse automation.

Whether you’re running a high-volume warehouse or a small manufacturing unit, now is the time to switch to smarter pallet tracking—without GPS.