In today’s electronics industry, flexible PCBs are becoming increasingly essential due to their versatility, durability, and compact design capabilities. Companies designing wearable devices, medical instruments, automotive electronics, and consumer gadgets require high-quality flexible PCB fabrication services to ensure reliable, efficient, and cost-effective production. Among the leaders in this field, FastTurn PCB stands out as a trusted partner for delivering superior flexible PCB manufacturing services that meet global standards.

- The Importance of Flexible PCB Fabrication

- FastTurn PCB: Expertise in Flexible PCB Manufacturing

- Advantages of Choosing FastTurn PCB

- 1. High-Quality Standards

- 2. Fast Turnaround Times

- 3. Expertise in Complex Designs

- 4. Global Reach

- 5. Cost-Effective Solutions

- Applications of Flexible PCB Fabrication

- Innovations in Flexible PCB Manufacturing

- Customer Success Stories

- Conclusion

The Importance of Flexible PCB Fabrication

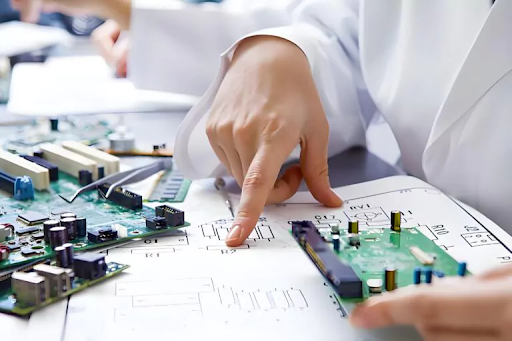

Flexible PCBs, or flex circuits, are designed to bend, fold, and conform to unique spaces without compromising electrical performance. They are particularly valuable in modern electronics where space constraints and design complexity are critical. Applications of flexible PCB fabrication include:

- Wearable devices like smartwatches and fitness trackers

- Medical electronics such as portable diagnostic equipment

- Consumer electronics including smartphones and tablets

- Automotive and aerospace systems requiring compact, reliable circuitry

- Industrial automation with complex, high-density electronics

Selecting a reliable manufacturer for flexible PCB fabrication is crucial for ensuring durability, performance, and consistency across all products. FastTurn PCB specializes in delivering high-precision flexible PCB solutions to meet these needs.

FastTurn PCB: Expertise in Flexible PCB Manufacturing

FastTurn PCB is a full-service provider of flexible pcb fabrication and manufacturing services. Their expertise covers a wide range of board types, materials, and applications. From single-layer flex circuits to complex multilayer and rigid-flex PCBs, FastTurn PCB ensures that each product is designed, fabricated, and tested to meet strict quality standards.

Key Services in Flexible PCB Fabrication

- Custom Flex PCB Design and Fabrication

FastTurn PCB works closely with clients to design flexible circuits optimized for manufacturability, performance, and cost-efficiency. Their engineers account for factors like bending radius, thermal requirements, and signal integrity to ensure optimal results. - Turnkey Assembly Solutions

Beyond fabrication, FastTurn PCB provides complete assembly services, including component sourcing, SMT and through-hole assembly, BGA placement, and functional testing. This turnkey approach streamlines the production process, saving clients time and resources. - Rapid Prototyping

FastTurn PCB offers fast-turn prototyping services, allowing clients to test and refine designs quickly. With turnaround times as short as 24–72 hours, engineers can validate functionality and performance before full-scale production. - Multilayer and Rigid-Flex PCBs

For complex applications requiring multiple layers or rigid-flex structures, FastTurn PCB delivers high-density, multilayer boards that maintain electrical integrity while conforming to design constraints. - Value-Added Services

FastTurn PCB also provides services such as BOM management, testing, and quality control to ensure that every flexible PCB meets international standards, including ISO 9001, UL, and RoHS compliance.

Advantages of Choosing FastTurn PCB

Partnering with FastTurn PCB for flexible PCB fabrication offers multiple benefits:

1. High-Quality Standards

Every flexible PCB undergoes rigorous inspection, including electrical testing, visual examination, and functional verification. Clients can trust that each board will perform reliably in real-world applications.

2. Fast Turnaround Times

With advanced equipment and streamlined processes, FastTurn PCB delivers prototypes and production runs quickly, helping clients accelerate product development and reduce time-to-market.

3. Expertise in Complex Designs

FastTurn PCB’s engineers have extensive experience with flexible, rigid-flex, and high-density PCBs, ensuring that even the most intricate designs are manufactured accurately.

4. Global Reach

Serving clients worldwide, FastTurn PCB provides reliable delivery, technical support, and supply chain solutions to companies in the United States, Europe, and Asia.

5. Cost-Effective Solutions

By providing both fabrication and assembly services under one roof, FastTurn PCB reduces supply chain complexity, minimizes production errors, and offers competitive pricing.

Applications of Flexible PCB Fabrication

FastTurn PCB’s flexible PCB solutions are used across multiple industries:

- Consumer Electronics: Wearables, smartphones, tablets, and IoT devices

- Medical Devices: Portable monitors, diagnostic equipment, and wearable medical electronics

- Industrial Automation: Robotics, control systems, and machinery electronics

- Automotive & Aerospace: Compact, high-performance circuits for navigation, avionics, and automotive electronics

- Telecommunications: Flexible circuits for networking devices and communication equipment

Flexible PCB fabrication enables designers to create smaller, lighter, and more reliable products, which is increasingly important in today’s electronics market.

Innovations in Flexible PCB Manufacturing

FastTurn PCB stays at the forefront of the industry by investing in cutting-edge technology and processes, including:

- High-Density Interconnect (HDI) PCBs for compact and complex designs

- Advanced flexible PCB materials for thermal, mechanical, and electrical performance

- Automated assembly and inspection for precision and consistency

- Environmentally friendly production adhering to RoHS and REACH standards

These innovations allow FastTurn PCB to deliver state-of-the-art flexible PCB solutions that meet the latest industry requirements.

Customer Success Stories

Many companies rely on FastTurn PCB for flexible PCB fabrication and assembly, ranging from startups to global manufacturers. One example involved a wearable technology client requiring a highly compact, multilayer flexible PCB with rapid prototyping and functional testing. FastTurn PCB delivered fully tested prototypes within 48 hours, enabling the client to move swiftly into production.

Such success stories highlight FastTurn PCB’s reliability, speed, and technical expertise, which are crucial for businesses looking to innovate and compete in the electronics market.

Conclusion

For electronics manufacturers seeking high-quality flexible PCB fabrication, FastTurn PCB offers unparalleled expertise, reliability, and comprehensive services. From flexible printed circuits to multilayer and rigid-flex boards, FastTurn PCB provides custom solutions, rapid prototyping, and turnkey assembly services to meet the needs of diverse industries.

Partnering with FastTurn PCB ensures faster product development, reduced risk, and superior quality, empowering clients to bring innovative electronics to market with confidence.

Learn more about their complete range of flexible PCB manufacturing services and see how FastTurn PCB can support your next project: