Choosing the right material for a printed circuit board (PCB) is one of the most consequential decisions an engineer will make. Get it right and your design achieves target performance, passes reliability testing on the first try, stays within budget, and survives years in the field. Get it wrong and you face excessive warpage, signal loss, premature failure, or costly re-spins.

In 2025, the range of available substrates, copper foils, and final finishes has never been broader—or more confusing. This comprehensive guide breaks down today’s most important options, their real-world trade-offs, and practical rules of thumb used by leading design teams.

1. The Core Decision: Base Laminate

FR-4 Family (Still King for Most Applications)

- Standard FR-4 (Tg 130–140 °C): cheapest, good enough for consumer, industrial, and most IoT products.

- Mid-Tg FR-4 (150–170 °C): modest cost increase, significantly better thermal reliability.

- High-Tg FR-4 (≥175 °C): mandatory for lead-free assembly and automotive under-hood.

- Halogen-free FR-4: now price-competitive with traditional; required by many OEMs.

Rule of thumb: Never specify standard Tg 130 °C FR-4 for new designs in 2025 unless cost pressure is extreme.

High-Frequency / Low-Loss Materials

When signal speeds exceed ~10 Gbps or RF extends into millimeter-wave:

- Rogers RO4000 series, Panasonic Megtron 6/7/8, Isola Astra MT77, I-Tera MT40

- Df (dissipation factor) as low as 0.001–0.003 vs 0.015–0.020 for FR-4

- Excellent Dk stability across frequency and temperature

Cost: 5–25× standard FR-4, but often justified because they eliminate the need for expensive shielding or longer traces.

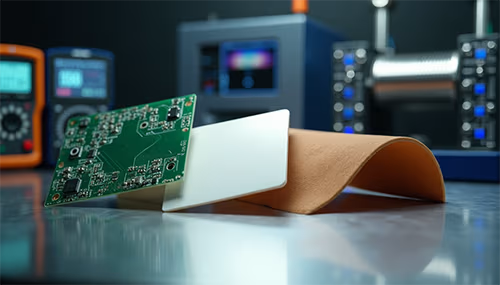

High-Thermal-Conductivity & Metal-Core (MCPCB)

- Aluminum or copper core with thin dielectric (50–200 µm)

- Thermal conductivity 1–8 W/m·K (vs ~0.3 W/m·K for FR-4)

- Ideal for high-power LED, automotive lighting, and motor drives

Flexible & Rigid-Flex Substrates

- Polyimide (PI): highest temperature rating, excellent flex life

- Polyester (PET): lower cost, limited to ~105 °C and fewer flex cycles

- Thin FR-4 cores (0.1–0.2 mm) with flex adhesives for rigid-flex

2. Copper Foil: Not All Copper Is Equal

- Standard electrodeposited (ED) copper: affordable, slightly rough surface

- Reverse-treat foil (RTF) and very low-profile (VLP): reduce skin-effect losses at >5 GHz

- Hyper-low profile (HVLP) and ultra-low profile foils now standard for 112 Gbps SerDes

For high-speed boards, specifying VLP or better is essentially free insurance against insertion-loss surprises.

3. Final Finishes: Protection vs. Cost vs. Assembly Process

| Finish | Cost | Shelf Life | Multiple Reflows | Wire Bonding | RoHS | Best For |

| HASL (lead-free) | $ | 12 mo | Poor | No | Yes | Low-cost, hand soldering |

| Immersion Tin | $$ | 6–12 mo | Fair | No | Yes | Flatness-critical |

| ENIG | $$$ | 12+ mo | Excellent | Yes | Yes | Most high-reliability |

| ENEPIG | 12+ mo | Excellent | Yes (gold & Pd) | Yes | Mixed SMT + wire bond | |

| Immersion Silver | $$ | 6–12 mo | Good | Limited | Yes | Cost-sensitive RF |

| Hard Gold (edges) | $$$$ | Long | Excellent | Yes | Yes | Connectors, frequent mating |

| OSP | $ | 6–12 mo | Fair | No | Yes | Single-pass consumer |

2025 trend: ENIG remains dominant, but ENEPIG is growing fast for automotive radar and 5G/6G modules that require both soldering and gold wire bonding on the same board.

4. Practical Decision Framework

Step 1 – Operating environment

- Temperature extremes → High-Tg or polyimide

- Vibration/shock → thicker cores, metal-backed

- Humidity/salt → conformal coating + robust finish

Step 2 – Electrical requirements

- 10 Gbps or RF → low-Dk/Df laminates + VLP copper

- Power density >20 W/in² → MCPCB or IMS

Step 3 – Assembly & lifetime cost

- Multiple reflow + long shelf → ENIG/ENEPIG

- Single reflow, <12 months → OSP or immersion silver

Step 4 – Regulatory & sustainability

- Halogen-free, REACH, RoHS, conflict minerals

5. Real-World Examples

- Consumer 5G smartphone: Megtron 8 + VLP copper + ENIG

- Automotive 77 GHz radar: Rogers RO3003 + ENEPIG (supports wire-bonded MMICs)

- High-power LED streetlight: Aluminum MCPCB + HASL

- Medical wearable: Thin polyimide flex + ENIG

- Enterprise 800 Gbps switch: Isola I-Tera MT40 + HVLP copper + ENIG

6. The Hidden Cost of the “Cheapest” Choice

A $2–3/m² savings on standard FR-4 can easily become a $200,000 re-spin if the board warps during lead-free assembly or fails thermal cycling at qualification. Leading companies now calculate total cost of ownership (TCO) rather than unit price alone.

Conclusion

Material selection is no longer a commodity decision left to the fabricator. In 2025, the smartest engineering teams treat laminate and finish choices as strategic design parameters that directly influence performance, reliability, and time-to-market.

The good news: modern PCB manufacturers have invested heavily in stocking high-performance materials, maintaining certified processes for low-loss and flex materials, and offering instant DFM feedback on material-specific rules. Partnering with a house that can guide you through the expanding matrix of options—rather than simply quoting the cheapest FR-4—is the difference between a product that merely works and one that dominates its category for years.

Choose wisely. The right material today determines whether your board survives tomorrow.