Nickel-plated steel strip coil is a vital industrial material offering outstanding durability, corrosion resistance, and conductivity. Whether you’re in the automotive, electronics, or construction sector, this specialized coil enhances both performance and longevity in manufacturing processes.

- Key Components:

- 1. Surface Preparation

- 2. Nickel Plating

- 3. Post-Treatment

- Corrosion Resistance

- Electrical Conductivity

- Mechanical Strength

- Thermal Stability

- H3: Automotive Industry

- Electronics and Electrical Engineering

- Renewable Energy

- Aerospace and Defense

- Medical Devices

- Benefits of Buying from Midwest Steel Supply:

- Growth Drivers:

In this comprehensive guide, we’ll explore what makes nickel-plated steel strip coil so valuable, how it’s produced, its wide range of uses, and where to source high-quality coils like the ones available from Midwest Steel Supply.

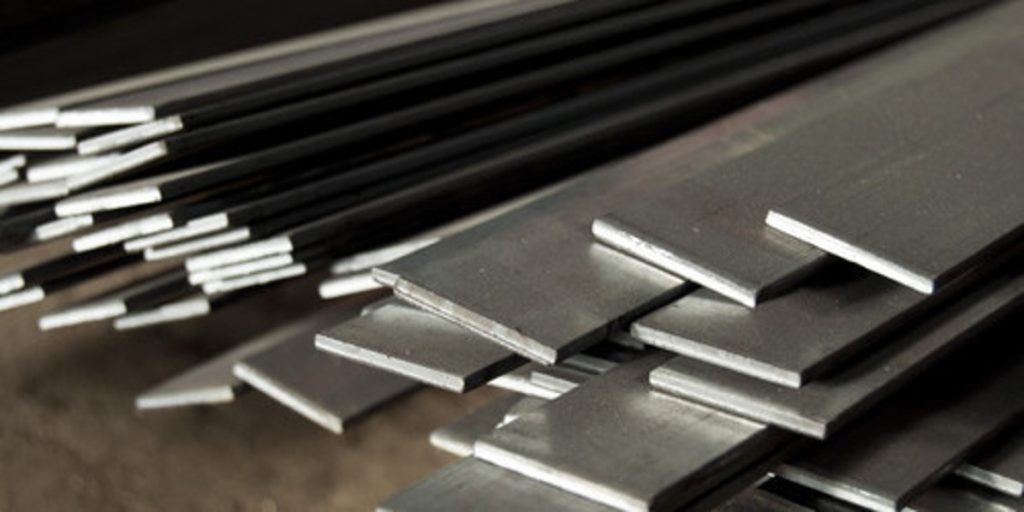

What Is a Nickel-Plated Steel Strip Coil?

A nickel-plated steel strip coil is a flat-rolled strip of steel that’s been electroplated or chemically coated with a thin layer of nickel. This coating offers several essential benefits, including corrosion resistance, high electrical conductivity, and a smooth, clean surface finish.

Key Components:

- Base Material: Cold-rolled carbon steel (SPCC), stainless steel (SUS304/SUS430), or other alloys.

- Nickel Layer: Pure nickel or nickel alloys plated to varying thicknesses (typically between 1–50μm).

- Surface Finish: Can be matte, semi-bright, or mirror-bright depending on the end use.

How Nickel-Plated Steel Strip Coils Are Manufactured

Understanding the production process of these coils helps clarify their performance benefits.

1. Surface Preparation

The base steel strip is cleaned using degreasing agents and acids to remove oxides and surface contaminants.

2. Nickel Plating

Two methods are used:

- Electroplating: Involves passing an electric current through a nickel solution to bond the nickel to the steel.

- Electroless Plating: A chemical reaction plates the nickel evenly across the surface without electricity.

3. Post-Treatment

After plating, the coil may undergo:

- Chromate passivation (for improved corrosion resistance)

- Heat treatment (to increase surface hardness)

- Lubrication or film coating (to prevent scratches during forming)

Key Properties of Nickel-Plated Steel Strip Coil

When comparing industrial materials, few offer the same combination of features as nickel-plated steel coils.

Corrosion Resistance

Nickel forms a passive oxide layer that protects the underlying steel from:

- Salt spray

- Acid and alkaline solutions

- Oxidation at high temperatures

This makes the material ideal for outdoor, high-moisture, or chemically exposed environments.

Electrical Conductivity

Nickel has excellent electrical properties, making the coil perfect for:

- Circuit connectors

- Bus bars

- Battery terminals

It combines well with copper and is solder-friendly.

Mechanical Strength

Nickel-plated steel strip coils maintain:

- High tensile strength

- Excellent wear resistance

- Low-friction surfaces

These qualities make it suitable for spring-loaded parts, stamping, and deep drawing.

Thermal Stability

Nickel-plated steel maintains integrity in high-heat environments, especially important in automotive and aerospace settings.

Applications of Nickel-Plated Steel Strip Coil

This coil material is found in nearly every major industrial sector.

H3: Automotive Industry

- Battery pack components

- EV terminals and busbars

- Exhaust components and interior trim

The automotive sector is experiencing a surge in demand for nickel-plated steel, driven by the global electric vehicle (EV) boom.

Electronics and Electrical Engineering

- Circuit connectors

- EMI/RFI shielding

- Flexible printed circuit boards

Its conductivity and solderability make it a top choice for manufacturers of electronic devices and printed circuit boards (PCBs).

Renewable Energy

- Solar panel connectors

- Wind turbine components

- Power inverters

The durability of nickel-plated steel makes it perfect for outdoor and renewable energy installations.

Aerospace and Defense

- Aircraft brackets

- Structural reinforcements

- Control and navigation systems

Aerospace requires materials that resist corrosion, vibration, and high temperature—qualities found in nickel-plated steel strips.

Medical Devices

Nickel’s antimicrobial qualities and clean finish make these strips useful for:

- Surgical tools

- Diagnostic equipment

- Medical enclosures

Why Choose Nickel-Plated Steel Strip Coils from Midwest Steel Supply?

If you’re sourcing nickel-plated steel strip coil for industrial use, choosing a reputable supplier is critical. Midwest Steel Supply offers precision-engineered products with excellent quality control and competitive pricing.

Benefits of Buying from Midwest Steel Supply:

- Consistent Coating Thickness: Ensures uniform conductivity and appearance.

- Multiple Grades Available: Choose from carbon steel, stainless steel, or customized options.

- Quick Delivery & Support: Reliable logistics and customer support.

- RoHS/REACH Compliant: Environmentally responsible manufacturing processes.

Global Market Trends and Forecast

The global market for nickel-plated steel strip coils is projected to grow significantly over the next five years.

Growth Drivers:

- Increased demand from EV battery production

- Expansion of 5G networks and smart devices

- Growth in solar and wind energy markets

- Miniaturization of electronics requires high-performance materials

According to DataIntelo, the market is expected to grow at a CAGR of over 5% from 2024 to 2030, with Asia-Pacific leading in production and consumption.

Final Thoughts

Nickel-plated steel strip coil is a vital material in today’s fast-moving industries. From the circuits in your electronics to the batteries in electric vehicles, these coils offer unmatched performance in durability, conductivity, and resistance to corrosion.

Whether you are in need of high-volume industrial supply or small custom runs, Midwest Steel Supply has the right solution for you.