The hunt for solution, more efficient power answers provides inserted oxyhydrogen technological know-how the main topic on innovation. In commercial apps ranging from metallic reduction in order to perfection welding, this interest in eco-friendly, high-performance natural gas age group techniques will continue to rise. Probably the most encouraging developments in this space is actually the style and also search engine marketing on the high-efficiency oxyhydrogen power generator, a head unit effective at developing hydrogen and also oxygen gas on-demand by means of electrolysis.

- Understanding the Oxyhydrogen Generator

- Key Components of a High-Efficiency Oxyhydrogen Generator

- Optimization Strategies for Maximum Efficiency

- Industrial Applications of Oxyhydrogen Technology

- Advantages of a High-Efficiency Oxyhydrogen Generator

- Challenges and Considerations

- Future Directions and Innovations

- Conclusion

This information explores these scientific disciplines, design guidelines, and also search engine marketing approaches driving oxyhydrogen machines that have a concentrate to be able to enhance their overall performance regarding commercial use. We’re going to also study real-world apps, security things to consider, and also long run chances in this enjoyable technology.

Understanding the Oxyhydrogen Generator

An oxyhydrogen generator is actually a computer making use of drinking water electrolysis to develop a stoichiometric combined hydrogen (H₂) and also oxygen (O₂) gas, commonly referred to as HHO gas. This mixture may be combusted to develop a clear flame, publishing merely drinking water steam to be a by-product—making it a good ecological option to fossil fuels.

The fundamental approach involves driving a good electric current via an electrolyte-infused drinking water remedy, leading to drinking water molecules to separate inside their component gases. The hydrogen and also oxygen tend to be next shipped to the point of make use of, generally without storage area, cutting down security threats involving high-pressure natural gas cylinders.

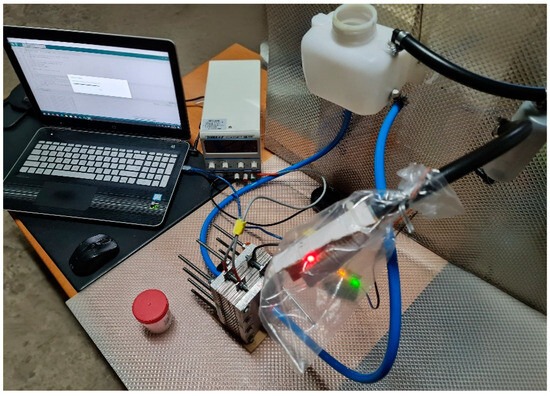

Key Components of a High-Efficiency Oxyhydrogen Generator

A new high-performance power generator requires mindful layout selections in several essential locations:

Electrolyzer Cell Design

The electrolyzer is actually the very center of the system, whereby drinking water molecules tend to be split. The plate product, spacing, and also setting have fun with significant positions within deciding efficiency.

- Electrode Fabric: Stainless-steel (316L) the type of option for its corrosion resistance, nonetheless superior films just like nickel or jewelry can certainly improve conductivity and also durability.

- Menu Spacing: Refining the length between number plates cuts down power resistance as well as heat age group, raising general natural gas output.

- Mobile phone Construction: Set and also similar preparations may be combined in order to steadiness voltage and also current demands.

Power Supply

The source of energy ought to give secure, variable current in order to optimise this electrolysis rate. Pulse-width modulation (PWM) remote controls tend to be notably helpful regarding handling power intake and also natural gas production.

Electrolyte Composition

Typical electrolytes incorporate blood potassium hydroxide (KOH) and also salt hydroxide (NaOH). The attentiveness impacts conductivity, overall performance, and also working temperature.

Gas Separation and Delivery

Though oxyhydrogen is usually utilized as a combined natural gas, superior techniques may combine flashback arrestors, drying techniques, and also filtering to guarantee natural gas chasteness and also secure delivery.

Optimization Strategies for Maximum Efficiency

The overall performance of an oxyhydrogen generator would depend on how properly the idea converts electrical energy into chemical substance power (gas production) using little losses.

Minimizing Energy Losses

- Reduce Inner Opposition: Improve electrode spacing and also surface to lessen voltage drop.

- Enhance Heat Administration: Employ cooling techniques to hold ideal working temperatures.

- Use PWM Know-how: Fine-tune current supply regarding top electrolysis efficiency.

Increasing Gas Output

- Electrode Surface area Treatments: Enrich natural gas percolate put out and stop scaling.

- Stream Administration: Ensure consistent electrolyte circulation to counteract scorching spots.

- Multi-Cell Options: Propagate more manual workload throughout multiple small solar cells regarding greater performance.

Safety Enhancements

High-efficiency designs also need to focus on security:

- Install flashback arrestors to counteract flames via traveling back into the cell.

- Employ solid elephant seals and also element proof against electrolyte corrosion.

- Observe natural gas results and also system strain continuously.

Industrial Applications of Oxyhydrogen Technology

Oxy-hydrogen generators usually are not tied to research laboratory experiments—they may have tested commercial relevance within multiple sectors.

Metal Cutting and Welding

Whenever employed in welding torches, oxyhydrogen produces a flame effective at reaching heat previously 2800°C. This kind of is perfect for precise, clear welding applications. A new special hydrogen welder features unparalleled perfection regarding dealers, digital camera portion companies, and also aerospace engineers.

Glass and Acrylic Work

Oxyhydrogen fire flames allow for smooth, bubble-free corners within cups and also polymer fabrication. The deficiency of carbon-based derivatives increases product understanding and also finish.

Engine Fuel Enhancement

In a few vehicle apps, small quantities of HHO natural gas tend to be presented into the air ingestion to raise combustion overall performance, possibly cutting down emissions.

Industrial Gas Supply

Large-scale techniques, this sort of being an industrial hydrogen generator, feature an on-demand supply of hydrogen and also oxygen regarding production functions, cutting down attachment to outside natural gas deliveries.

Advantages of a High-Efficiency Oxyhydrogen Generator

- Eco-Friendly Procedure: Makes nil dangerous pollutants; really the only by-product is actually drinking water vapor.

- On-Demand Petrol Manufacturing: Minimizes the necessity for high-pressure storage.

- Cost-Effective Above Period: Minimizes fees connected with natural gas expenditures and also storage area logistics.

- Flexibility: Pertinent throughout various market sectors, via perfection welding in order to large-scale manufacturing.

Challenges and Considerations

Whilst oxyhydrogen technological know-how features many benefits, makers ought to correct major issues:

- Energy Utilization: Devoid of search engine marketing, electrolysis may be energy-intensive.

- Fabric Strength: Prolonged exposure to electrolytes can certainly lower components.

- Wellbeing Pitfalls: Incorrect coping with can lead to flashbacks or leaks.

Approaching these issues by means of sensible layout, normal repair, and also security education makes certain trusted long-term performance.

Future Directions and Innovations

Research into oxyhydrogen technological know-how will continue to explore innovative frontiers:

- Nanostructured Electrodes: Much better exterior components regarding bigger reaction rates.

- Hybrid car Energy Solutions: Bringing in photo voltaic or blowing wind power using oxyhydrogen age group regarding carbon-neutral production.

- AI-Powered Handle Solutions: Real-time search engine marketing based upon weight needs and also environment conditions.

With one of these new developments, this overall performance and also re-homing regarding oxyhydrogen techniques will probably increase easily over the coming decade.

Conclusion

The style and also search engine marketing on the high-efficiency oxyhydrogen generator is often a multi-faceted design concern that mixes electrochemistry, elements of scientific disciplines, and energy management. By means of polishing major components—via electrode elements in order to electricity supply systems—companies can certainly generate techniques that are both cost-effective and also green sustainable.

Seeing that market sectors seek out solution power answers, oxyhydrogen technological know-how is unique as a flexible, scalable, and also eco-friendly alternative. No matter if regarding perfection welding, commercial natural gas delivery, or cutting-edge investigation, the future of oxyhydrogen appears to be bright—pushed by means of continuous development and also a universal push when it comes to sustainability.

Need more details? Visit: Oxyhydrogen Generator