Introduction

In the world of material fabrication, selecting the right grinding wheel is crucial for achieving desired results. Among the various options available, CBN grinding wheels stand out for their unique properties and advantages. This article explores how CBN grinding wheels compare to other types of grinding wheels and when they are the preferred choice.

- Introduction

- Understanding Different Grinding Wheel Types

- Aluminum Oxide Grinding Wheels

- Silicon Carbide Grinding Wheels

- Diamond Grinding Wheels

- CBN Grinding Wheels

- Why Choose CBN Grinding Wheels for Material Fabrication?

- 1. Optimized for Ferrous Materials

- 2. Longer Wheel Life

- 3. High Precision and Stability

- 4. Reduced Heat Damage

- CBN vs. Other Grinding Wheels: A Quick Comparison

- Conclusion

Understanding Different Grinding Wheel Types

Before comparing, it’s important to know the basic categories of grinding wheels:

Aluminum Oxide Grinding Wheels

- Common and cost-effective.

- Best suited for softer steels and general-purpose grinding.

- Short lifespan compared to superabrasive wheels.

Silicon Carbide Grinding Wheels

- Harder than aluminum oxide.

- Often used for non-ferrous materials like brass, aluminum, and soft metals.

- Wears down quickly on harder steels.

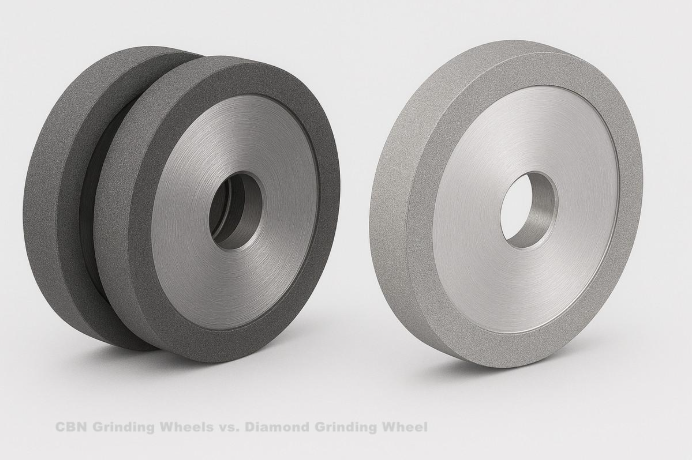

Diamond Grinding Wheels

- Hardest known abrasive.

- Best for non-ferrous materials such as tungsten carbide, ceramics, glass, and stone.

- Not suitable for grinding ferrous materials (steel) due to chemical reactions at high heat.

CBN Grinding Wheels

- Second only to diamond in hardness.

- Specially engineered for ferrous materials, including hardened steel, tool steels, and cast iron.

- Long-lasting, precise, and ideal for high-production environments.

Why Choose CBN Grinding Wheels for Material Fabrication?

1. Optimized for Ferrous Materials

While diamond grinding wheels excel at cutting carbide tools, ceramics, and composites, CBN wheels are designed for steel-based alloys. This makes them the preferred choice in industries such as automotive, aerospace, and tool manufacturing.

2. Longer Wheel Life

Compared to conventional abrasives like aluminum oxide or silicon carbide, CBN grinding wheels last significantly longer. This reduces downtime for wheel changes and lowers overall operational costs.

3. High Precision and Stability

CBN wheels maintain their shape throughout the grinding process, ensuring consistent accuracy—critical when fabricating precision components like gears, shafts, or cutting tools.

4. Reduced Heat Damage

CBN has excellent thermal stability. This means less heat build-up, reduced risk of thermal cracking, and a superior surface finish.

CBN vs. Other Grinding Wheels: A Quick Comparison

| Grinding Wheel Type | Best for | Limitations |

|---|---|---|

| Aluminum Oxide | General-purpose grinding of mild steels | Short lifespan, limited precision |

| Silicon Carbide | Non-ferrous metals, softer materials | Wears out quickly on hard steels |

| Diamond Wheels | Carbide, ceramics, glass, non-ferrous materials | Cannot be used on steels |

| CBN Grinding Wheels | Hardened steels, tool steels, cast iron | Higher initial cost, but best long-term performance |

Applications of CBN Grinding Wheels in Material Fabrication

- Cutting Tool Sharpening – Ideal for HSS tools and regrinding drills, end mills, and reamers.

- Automotive Components – Used for crankshafts, camshafts, and gears.

- Aerospace Parts – High-strength steels and alloys for turbine components.

- Die and Mold Industry – Precision finishing of hardened steel molds.

- Machine Shops – General tool sharpening with CBN wheels for Tormek or bench grinders.

Choosing Between CBN and Diamond Grinding Wheels

- For tungsten carbide tools, ceramics, and glass → Choose diamond grinding wheels.

- For steel-based materials (hardened steels, cast iron, high-speed steels) → Choose CBN grinding wheels.

This is why both wheel types are considered complementary rather than competitors in modern manufacturing.

Conclusion

When it comes to material fabrication, choosing the right grinding wheel ensures productivity, precision, and cost-efficiency. While aluminum oxide and silicon carbide wheels are suitable for basic grinding tasks, they cannot match the durability and performance of superabrasives.

- Diamond grinding wheels remain the best for tungsten carbide and non-ferrous materials.

- CBN grinding wheels are unmatched for ferrous materials, making them the best choice for industries like automotive, aerospace, and tool manufacturing.

At Superabrasive Tools, Xinxiang New Zuan Diamond Tools Co., Ltd. provide high-performance CBN wheels, diamond wheels, diamond sharpening wheels, and specialized grinding solutions to meet diverse industrial needs.