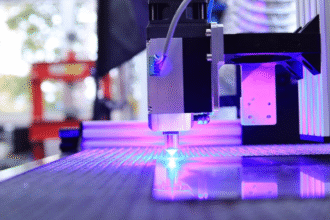

In today’s fast-paced electronics industry, the demand for innovative, compact, and high-performance circuit boards continues to rise. Among the most versatile solutions available is the rigid-flex PCB, a technology that combines the strength of rigid boards with the flexibility of flexible substrates. As a premier rigid-flex PCB manufacturer and supplier in China, we specialize in delivering robust rigid-flex PCB fabrication that seamlessly integrates both rigid and flexible layers. Whether you are looking for prototype production or high-volume manufacturing, our services are tailored to meet the demands of modern electronics design.

What is a Rigid-Flex PCB?

A rigid-flex PCB is a hybrid circuit board that combines the properties of traditional rigid PCBs with flexible circuits. This combination allows for reduced size and weight, improved reliability, and enhanced performance. Engineers often choose rigid-flex boards for applications where space is limited, such as medical devices, aerospace systems, wearable technology, and advanced industrial electronics.

From my experience, working with multilayer rigid flex PCB designs requires precision and an understanding of both mechanical and electrical constraints. A well-fabricated rigid-flex board can dramatically simplify assembly and reduce potential points of failure in a device.

Advantages of Multilayer Rigid-Flex PCBs

Enhanced Durability and Reliability

Unlike traditional PCBs, rigid-flex boards are less prone to mechanical stress and vibration damage. The flexible layers act as shock absorbers, reducing the risk of cracked solder joints or damaged components. In applications like aerospace or automotive electronics, this reliability is not just beneficial—it is critical.

Space and Weight Savings

One of the primary benefits of rigid-flex PCB fabrication is its ability to save space and weight. By combining multiple rigid boards with flexible interconnections, designers can fold, twist, and fit the circuitry into compact enclosures without compromising performance. During a recent project, I noticed that transitioning from standard PCBs to multilayer rigid-flex PCB designs allowed us to reduce the device size by almost 30%, while maintaining full functionality.

Streamlined Assembly Process

Because rigid-flex PCBs reduce the need for connectors and wiring between separate boards, assembly time is significantly shortened. This simplification lowers the risk of human error and improves overall manufacturing efficiency. For clients aiming for high-volume production, this is a major advantage.

Our Expert Rigid-Flex PCB Fabrication Services

As a leading rigid-flex PCB manufacturer, we provide comprehensive services covering every stage of production. From concept and prototyping to mass manufacturing, our team ensures high-quality results for all types of projects.

Prototype and Quick-Turn Services

For engineers and designers who need fast turnaround times, our rigid-flex PCB fabrication services support quick prototyping. Simply upload your Gerber files, and we will provide a competitive, fast quote. This rapid service allows teams to iterate designs efficiently, testing and refining without lengthy delays.

Multilayer Rigid-Flex PCB Production

Our facility specialises in multilayer rigid flex PCB fabrication, supporting complex designs that require multiple signal, power, and ground layers. With precise control over layer alignment, material selection, and impedance management, we deliver boards that meet stringent performance and reliability standards.

From personal experience, collaborating closely with the manufacturer during the multilayer design process can save significant time. It ensures that the board functions perfectly while avoiding common pitfalls like layer misalignment or excessive thermal stress.

High-Volume Manufacturing

For large-scale projects, we provide high-volume production capabilities without compromising quality. Our advanced manufacturing processes and rigorous quality control allow us to consistently deliver superior rigid-flex boards to clients worldwide. Each batch undergoes thorough inspection to ensure it meets exacting standards before shipment.

Applications of Rigid-Flex PCBs

Rigid-flex PCBs are highly versatile and used across various industries. Some common applications include:

Medical Devices: Flexible yet durable circuits for diagnostic equipment and wearable health monitors.

Aerospace and Defence: Lightweight boards capable of withstanding high stress and vibration.

Consumer Electronics: Compact devices such as smartphones, tablets, and smartwatches.

Industrial Equipment: Robust boards for machinery requiring high reliability in harsh environments.

Robust boards for machinery requiring high reliability in harsh environments.

Having worked on multiple projects that involved rigid-flex designs, I’ve seen firsthand how their adaptability can unlock design innovations that are impossible with traditional PCBs. The ability to bend, fold, or integrate multiple rigid sections in one seamless unit is a game-changer for product engineers.

Why Choose Us as Your Rigid-Flex PCB Supplier?

Selecting the right rigid-flex PCB manufacturer is crucial for achieving high-quality results. Here’s why our clients trust us:

- Expertise in Multilayer Rigid-Flex PCB Fabrication: We have years of experience producing complex, multilayer boards with precise tolerances.

- Seamless Integration: Our fabrication process ensures that rigid and flexible layers are perfectly integrated for maximum performance.

- Quick Quotes and Fast Turnaround: Upload your Gerber files, and we provide a competitive quote in no time.

- Global Supply Capability: We support both prototype and high-volume production, shipping reliable boards worldwide.

From my professional experience, having a manufacturer who understands both the technical and practical aspects of rigid-flex design can save substantial time and cost. The difference between a standard manufacturer and a true rigid-flex expert is the ability to anticipate challenges before they arise.

Conclusion

The evolution of electronics demands smarter, smaller, and more reliable solutions. Rigid-flex PCBs offer an elegant solution by combining the durability of rigid boards with the adaptability of flexible circuits. As a trusted rigid-flex PCB manufacturer and supplier in China, we pride ourselves on delivering high-quality rigid-flex PCB fabrication that meets the unique requirements of modern applications.