An appropriate tolerance range is essential in the world of custom sheet metal fabrication for accuracy and cost. When it comes to sheet metal manufacturing, maintaining tight tolerances may be challenging. Low-quality products and project delays can arise from inconsistent results. Many manufacturers are facing issues regarding the failure to fit the part due to poor tolerance management.

This guide will help you navigate the complexities of sheet metal tolerances. Are you prepared to learn how to improve your processes and become an expert in the art of accuracy in sheet metal manufacturing? Let’s get started!

What Is Sheet Metal Tolerance?

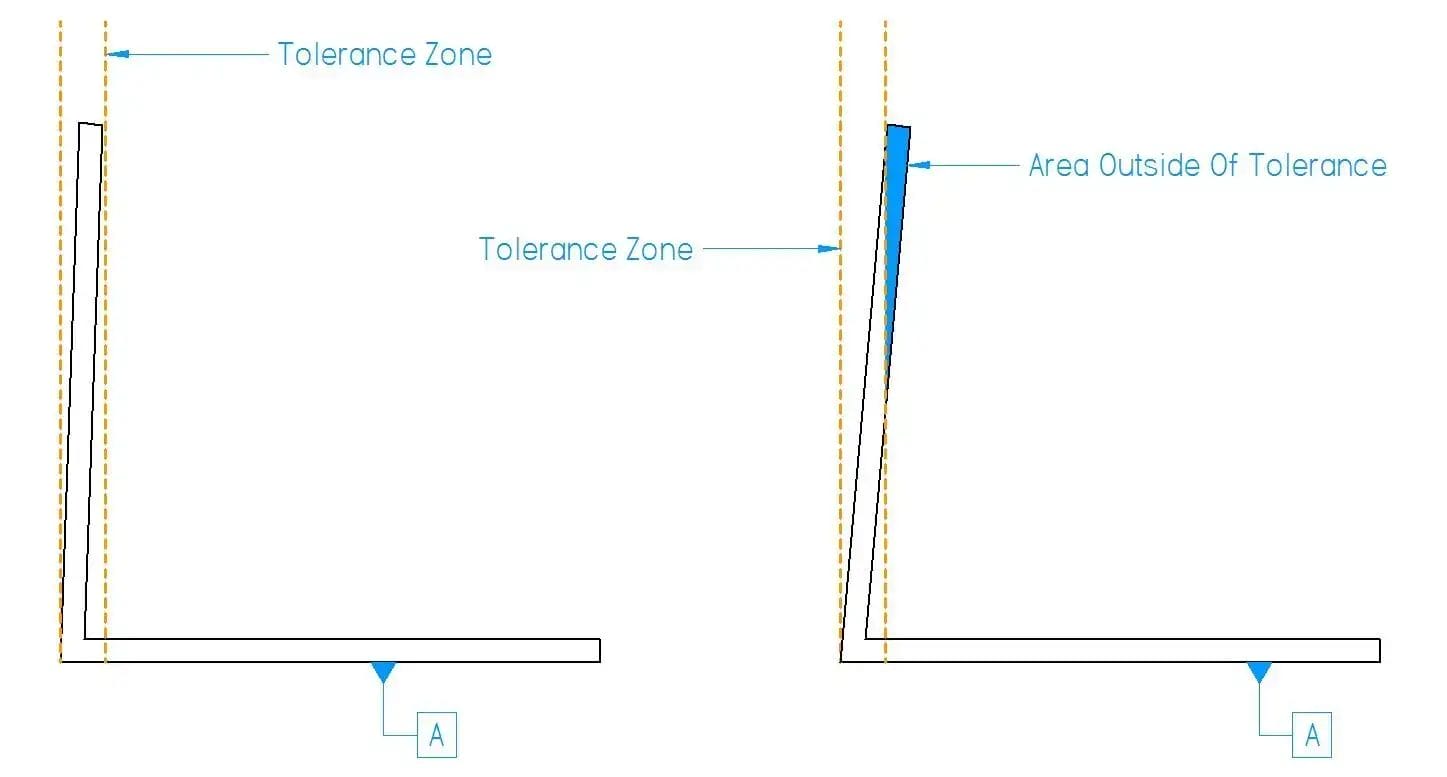

Sheet metal tolerance can be defined as a range that permits variations in the design dimensions of parts. The upper and lower limits of the variable design size of a workpiece come under the manufacturing tolerances range. Tolerances are widely used in sheet metal fabrication and are essential for guaranteeing the accuracy of sheet metal parts.

Sheet Metal Fabrication Tolerances

Manufacturing tolerance range is the permissible range of deviation from measurements or specific dimensions for a manufactured part or component. Tolerances for sheet metal fabrication usually fall between ±0.00787 and ±0.060.

Moreover, the upper and lower deviations establish the tolerance zone of the sheet metal tolerance. Tighter tolerances have a smaller range of upper and lower limits, whereas looser tolerances have a larger tolerance zone. The workpiece’s dimensions are also more accurate when the tolerances are tighter. This enables us to achieve high tolerances.

Why Sheet Metal Tolerance Is Important?

Tolerances are crucial in manufacturing for six primary reasons:

- Enhance part fit and functionality: It is important because a minor inaccuracy in size or dimension will render your product incompatible or functionally worthless.

- Enhance the final product’s appearance: Tolerances act as a good aesthetic. Hence, sheet metal tolerances regulate the position and dimensions to sit flat against another part without any gap between them.

Tight Flatness Tolerances

- Allow for a fair amount of error: Tolerances only allow for a certain amount of error as long as the part continues to function.

- Manufacturing is more economical: A product is only as accurate as necessary when your tolerances are defined. This implies that you will only be charged for the labour, supplies, and manufacturing equipment that are truly required to get the intended outcome.

- Reach the products to market faster: Determining tolerances upfront may take a bit longer, but it will ultimately save you time.

- Tolerances reduce ambiguity: Tolerances eliminate all complexity from the equation. Producers shouldn’t strain themselves to meet this high level of accuracy if their product doesn’t need to be exact within ±0.002mm.

Hence, clearly defining the tolerances during design will help to achieve the desired product as intended and it will also be cost effective. The harder part of tolerance is the decision of whether tight or loose tolerances should be used.

Types of Sheet Metal Tolerances

Sheet metal tolerances can take many different forms, such as flange length, width, thickness of the sheet, thickness of the wall, bends, curls, countersinks, hems, holes, slots, notches, and

tabs in sheet metal fabrication. Few are here:

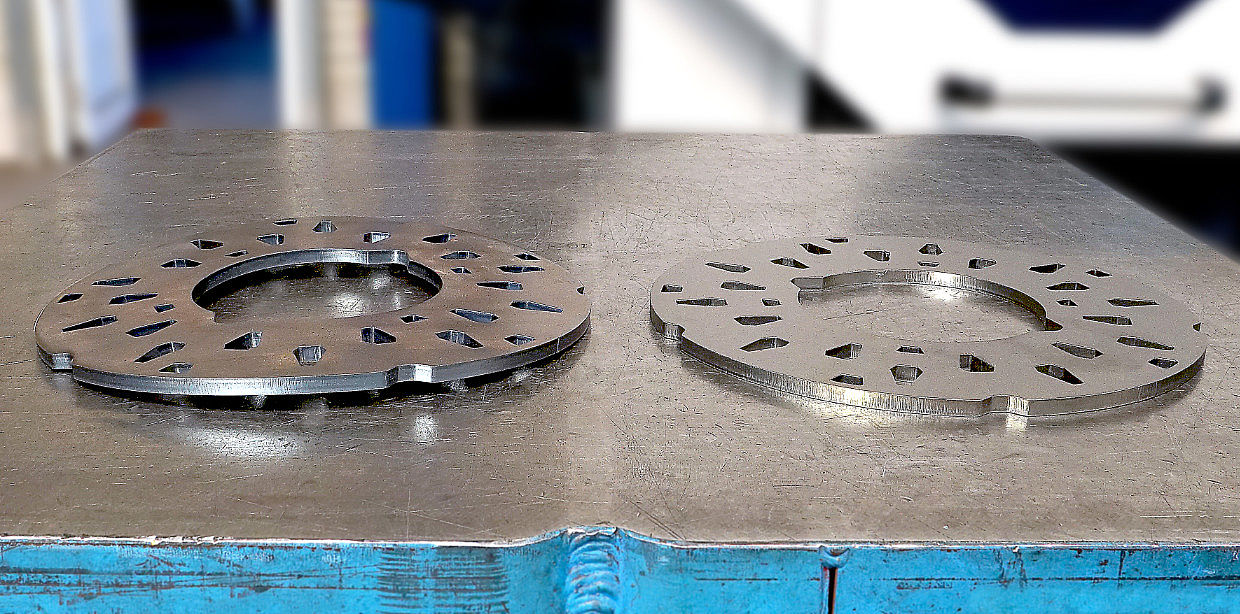

- Dimensional Tolerances: The permitted size variations in sheet metal components are known as dimensional tolerances. These tolerances guarantee that parts will fit together as intended, despite slight production deviations. The linear tolerances ensure the length, width, and height of the part. Angular tolerances define the precise angle of a part in sheet metal bending operations.

Types of Sheet Metal

- Geometric Tolerances: The positioning of features and the shape form of a component are addressed by geometric tolerances. These tolerances guarantee that parts fit into an assembly and keep their intended shape. The form tolerance ensures the flatness, straightness, and circularity of a surface. And the position tolerance ensures holes and slots align perfectly during assembly.

- Material Tolerances: The possible tolerances in sheet metal manufacturing are greatly influenced by the qualities of the material. Material thickness and properties play a key role in determining the achievable tolerances.

- Process-Specific Tolerances: The fabrication process itself imposes particular tolerance restrictions.

The manufacturers mostly use the typical metric manufacturing system in the metric system. Here is the simple guide:

| Process | Type | Tolerance Value |

| Laser Cutting | Linear dimensions | ±0.1mm for parts up to 1000mm |

| Hole diameter < 5mm | ±0.05mm | |

| Hole diameter > 5mm | ±0.1mm | |

| Punching | Linear dimensions | ±0.2mm for parts up to 1000mm |

| Hole diameter | ±0.1mm | |

| Bending | Angular tolerance | ±0.5° |

| Linear dimensions | ±0.3mm for bends up to 1000mm | |

| Stamping | Linear dimensions | ±0.2mm for parts up to 100mm |

| ±0.3mm for parts 100-500mm | ||

| Forming | Linear dimensions | ±0.5mm for formed features up to 100mm |

| ±0.8mm for formed features 100-500mm | ||

| Welding | Linear dimensions | ±0.5mm for weld lengths up to 100mm |

| ±1.0mm for weld lengths 100-500mm |

Sheet Metal Bending Tolerances

Sheet Metal Bending Tolerances

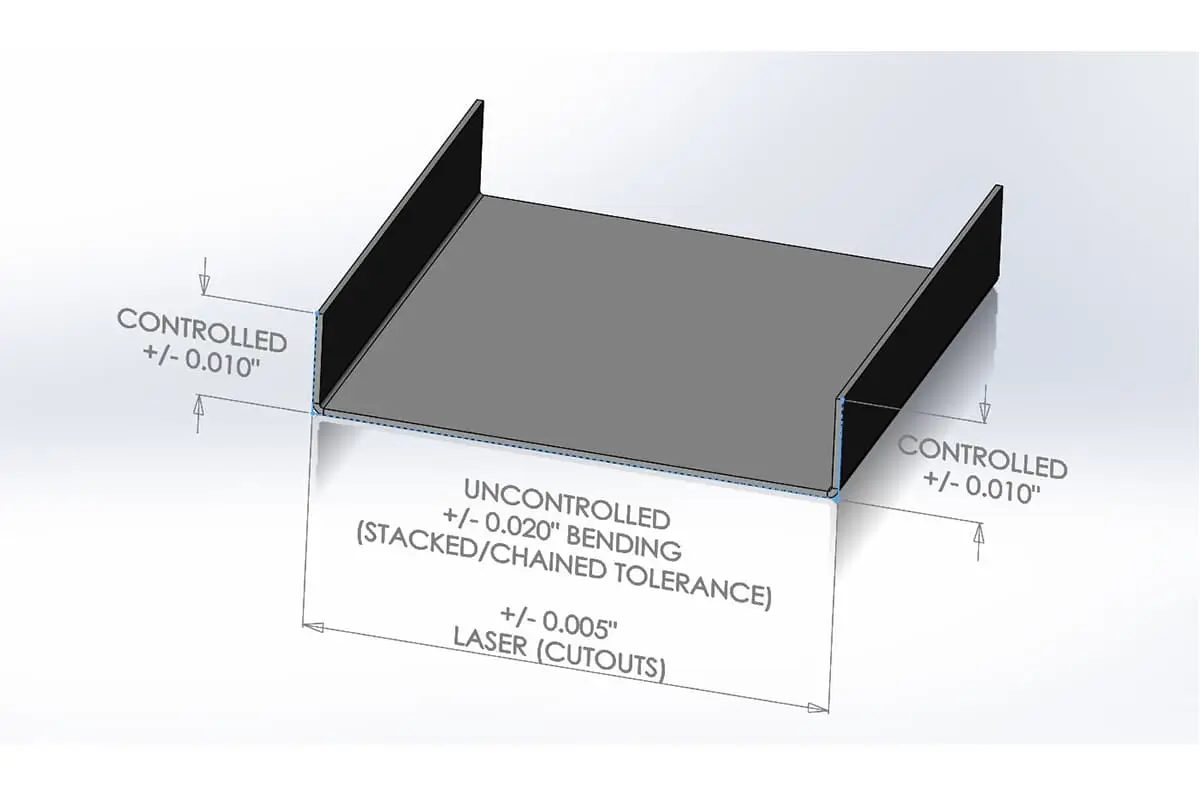

Sheet metal bending tolerances go along with either an uncontrolled or a controlled dimension. The length of the flange on any bend is referred to as a controlled dimension. Because controlled dimension bend tolerances are independent, no other bend needs to be taken into account. Conversely, uncontrolled dimensions describe the portions of the component from which the bend originated.

| Bending Process | Tolerance |

| Bend angle | ±1 degree |

| Bend length | ± 0.010″ | 0.25 mm |

Hence, the application of the k-factor and bend deduction is used to bend the material position accurately.

Sheet Metal Thickness Tolerance

It is important to consider the rolling sheet metal thickness tolerance when designing a tight-fitting assembly, especially when the material becomes thicker. The processing mill produces and delivers sheet metal that has been rolled to the standard thickness you designate.

Hence, consulting the manufacturer’s datasheet is essential for material-specific thickness tolerance, as it affects the materials’ forming, cutting, and welding.

Factors That Influence Tolerances

Several factors influence actual tolerances in sheet metal fabrication:

Material Selection: There are inherent tolerances in the type and thickness of the selected material.

Accuracy of Equipment: The accuracy of various manufacturing equipment and machinery varies. Achieving particular tolerance levels depends in part on the equipment’s precision capability.

Process Sophistication: A part’s capacity to maintain strict tolerances is strongly impacted by the number of procedures it goes through. This phenomenon is known as tolerance stack-up.

Environment and Temperature: Sheet metal tolerances are greatly impacted by temperature and environmental factors, particularly for materials that are sensitive to temperature changes or parts that have strict tolerances.

Fabrication Producers’ Capabilities: Pre-engagement is crucial for bringing expectations and capabilities into alignment because the company’s capacity to meet certain tolerance requirements is impacted by the range of capabilities.

Collaboration with your sheet metal fabrication partner is crucial during the design phase to optimise results.

Innovations of Tolerances in Sheet Metal Fabrication

With the following predicted developments, tolerances in sheet metal fabrication are expected to become increasingly accurate and efficient in the future.

AI training technologies will completely transform the way companies manage and apply tolerances. They may anticipate and address problems before they arise by examining production process data, which results in more accurate manufacturing procedures.

As sustainability gains international attention, there will be a greater focus on waste reduction and material optimization. Tolerances are crucial in this endeavour as tighter control over material dimensions can lead to more effective utilisation.

The capacity to swiftly modify tolerances to satisfy particular client needs will become more crucial as sectors shift toward customised production and on-demand manufacturing.

Hence, an ideal sheet metal services provider must offer transparent tolerance guidelines, making sure CAD designs adhere to Design for Manufacturing (DFM) standards in order to set reasonable and attainable tolerances.

However, every sheet metal service provider may follow ISO guidelines.

Conclusion

Learning sheet metal tolerances is important for making outstanding parts. Important things manufacturers should consider include material properties, choosing appropriate processes, considering design factors, and following industry standards. Close control of tolerances guarantees part functionality, interchangeability, and product quality.

So, decide your tolerances clearly before initiating your next project. Compare them with your custom sheet metal fabrication partner to ensure accuracy and cost efficiency throughout the project.