In the complex world of heavy industry and automation, the difference between a successful project and a maintenance nightmare often comes down to a single component: the rotation system. While many procurement managers look solely at specs like torque or gear ratio, experienced engineers know that the real value lies in the design expertise behind the hardware.

When integrating a slew drive into a crane, aerial platform, or solar tracker, “off-the-shelf” solutions rarely offer the perfect fit. This is where the caliber of your manufacturing partner becomes the deciding factor.

The Value of 15 Years of Engineering Heritage

At Lyra Drive (Luoyang Slewring Bearing Co., Ltd.), we have spent over 15 years perfecting the art of motion control. Our philosophy is simple: We don’t just sell parts; we engineer solutions.

A standard catalog product might meet 90% of your requirements, but the missing 10%—whether it’s a specific environmental seal, a unique motor interface, or a tighter backlash tolerance—is often where failures occur. Our veteran engineering team bridges this gap. We leverage deep industry data to predict how a drive will behave under real-world stress, ensuring reliability long before the equipment hits the field.

Simulation and Calculation: Design Before Manufacturing

The strength of Lyra Drive lies in our pre-production support. Our engineers act as an extension of your own design team.

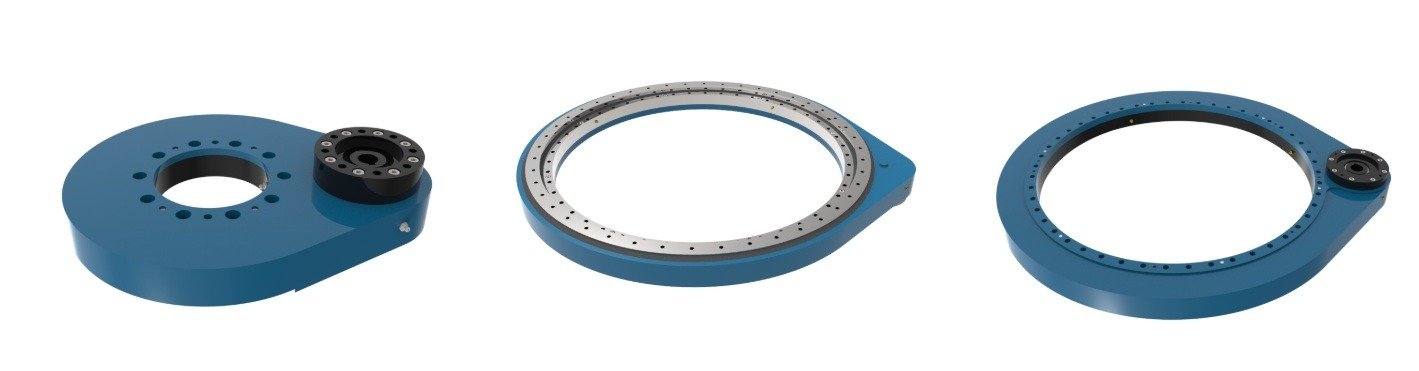

Before we recommend a specific model—whether it’s our SE (Enclosed), WE (Heavy Duty), or SP (High Speed) series—we conduct rigorous analysis. We evaluate:

- Load Dynamics: Detailed calculation of axial, radial, and tilting moment loads.

- Application Environment: Assessing the need for IP-rated sealing against dust, rain, or salt spray.

- Precision Requirements: Determining if a standard drive suffices or if a high-precision design (up to P0-P2 levels) is necessary.

This “consultation-first” approach prevents the common pitfall of under-engineering (risking safety) or over-engineering (wasting budget).

Mastering the Spectrum: From Worm to Spur Gears

True engineering capability is shown through versatility. While many suppliers are limited to basic designs, Lyra Drive offers a comprehensive range of customized technologies:

- Worm Gear Solutions: Ideal for construction machinery and cranes where self-locking safety and high torque are non-negotiable.

- Spur Gear Drives (SP Series): Engineered for the high-speed, dynamic requirements of industrial automation and robotics, providing low friction and rapid positioning.

- Large-Scale Customization: We possess the manufacturing power to produce roller slewing bearings up to 5000mm in diameter, tailored for massive port machinery or tunnel boring machines.

A Service-Oriented Partnership

The transition from traditional, high-maintenance open slewing bearings to modern, integrated sealed drives is a significant upgrade. However, making this switch requires guidance.

Our service extends beyond the factory floor. From the initial concept phase, where we provide 3D models for your system integration, to the final validation phase, Lyra Drive’s engineers are dedicated to your project’s success. We ensure that the drive you install is not just a component, but a strategic asset that lowers your Total Cost of Ownership (TCO) and extends the lifecycle of your machine.

Conclusion

In an industry demanding higher precision and longer service life, you need more than a supplier—you need a design partner. With expert engineering, diverse customization capabilities, and a commitment to service, Lyra Drive ensures your equipment rotates with confidence.