In industrial automation, the reliability of control systems can mean the difference between seamless operations and costly downtime. When safety-critical processes are at stake, engineers cannot afford to compromise on component quality. HIMA Z7138 components have established themselves as essential building blocks in safety instrumented systems, providing the precise control and fail-safe operation that modern industrial facilities demand. However, sourcing these specialized components presents a unique challenge, particularly when projects operate under tight budget constraints or require rapid replacement of legacy equipment.

Refurbished HIMA Z7138 parts offer an attractive alternative to new components, delivering significant cost savings while supporting sustainability initiatives through equipment reuse. Yet the refurbished market comes with its own complexities—quality varies widely between suppliers, and understanding warranty protections becomes crucial for long-term operational success. This article explores practical strategies for locating high-quality refurbished z7138 components, evaluating supplier credibility, and navigating warranty considerations to ensure your automation projects maintain both reliability and budget efficiency.

Understanding HIMA Z7138 Control Systems

HIMA specializes in safety-related automation solutions that protect personnel, equipment, and the environment in high-risk industrial settings. Their control systems form the backbone of safety instrumented systems across petrochemical plants, power generation facilities, and manufacturing operations where process failures could result in catastrophic consequences. The company’s reputation rests on delivering systems that meet stringent international safety standards including IEC 61508 and IEC 61511, providing the redundancy and fail-safe mechanisms that critical operations require.

The Z7138 component functions as a central processing module within HIMA’s safety systems, handling real-time monitoring and control tasks that keep industrial processes within safe operating parameters. This module processes input signals from field sensors, executes safety logic programs, and triggers protective actions when hazardous conditions are detected. Engineers integrate Z7138 modules into emergency shutdown systems, fire and gas detection networks, and burner management applications where split-second response times prevent accidents. The module’s architecture incorporates diagnostic capabilities that continuously verify system integrity, alerting operators to potential issues before they compromise safety functions.

Industrial facilities choose HIMA systems for operations where failure is not an option. The Z7138’s proven track record in demanding environments, combined with its ability to integrate with existing infrastructure, makes it a preferred choice for both new installations and system upgrades. Its modular design allows engineers to scale systems according to specific safety requirements while maintaining compliance with industry regulations. For facilities operating legacy HIMA systems, the Z7138 represents a critical component whose availability directly impacts operational continuity and safety certification maintenance.

Benefits of Refurbished HIMA Z7138 Components

Financial pressures drive many industrial facilities to reconsider their approach to automation component procurement. Refurbished HIMA Z7138 modules typically cost 40-60% less than new equivalents, freeing capital for other critical infrastructure investments while maintaining the same functional capabilities. This cost advantage becomes particularly significant for facilities managing multiple safety systems or planning extensive upgrades across aging installations. Budget-conscious projects can allocate saved funds toward additional redundancy measures, enhanced monitoring equipment, or operator training programs that further improve overall safety performance.

Beyond immediate cost benefits, choosing refurbished components supports circular economy principles that resonate with corporate sustainability commitments. Manufacturing new electronic components consumes significant raw materials and energy, whereas refurbishment extends the useful life of existing hardware through testing, repair, and component replacement. Facilities pursuing environmental certifications or carbon reduction targets find that sourcing refurbished automation parts contributes measurably to their sustainability metrics. This approach aligns with growing industry recognition that responsible resource management extends beyond operational processes to include procurement decisions.

Concerns about refurbished component reliability often prove unfounded when parts undergo rigorous professional restoration. Reputable refurbishers subject Z7138 modules to comprehensive testing protocols that verify functionality across all operational parameters, often matching or exceeding the quality checks performed on new units. The refurbishment process addresses wear-related issues, replaces components showing degradation, and validates performance against original specifications. Many refurbished modules come from facilities that upgraded systems before reaching end-of-life, meaning the underlying hardware retains substantial operational capacity.

Quality Standards for Refurbished Parts

Professional refurbishment follows structured processes that restore components to reliable operational status. Qualified technicians disassemble modules for thorough inspection, identifying circuit boards requiring repair, connectors showing corrosion, or capacitors approaching failure thresholds. Specialized test equipment simulates real-world operating conditions, measuring response times, signal accuracy, and fault detection capabilities to confirm the module meets HIMA’s published specifications. Documentation accompanying quality refurbishment includes test results, replaced component lists, and calibration certificates that provide transparency into the restoration work performed.

Verifying refurbishment quality requires examining specific supplier practices before committing to purchases. Request detailed information about testing procedures, including whether suppliers use HIMA-approved diagnostic tools and follow manufacturer-recommended protocols. Legitimate refurbishers willingly share their quality management certifications, such as ISO 9001 accreditation, which demonstrates adherence to systematic quality control processes. Ask for sample test reports from previous refurbishment batches to assess documentation thoroughness and technical competence. Suppliers offering vague descriptions of their refurbishment process or refusing to provide verification documentation should raise immediate concerns about their quality standards and technical capabilities.

Where to Source Quality Refurbished Z7138 Parts

HIMA maintains an authorized network of service centers and certified partners that handle component refurbishment according to factory specifications. These authorized facilities access original equipment manufacturer (OEM) technical documentation, use genuine replacement parts, and employ technicians trained directly by HIMA engineers. Contacting HIMA’s regional offices provides referrals to authorized refurbishment centers serving your geographic area, ensuring components receive factory-grade restoration. While authorized channels typically command premium pricing compared to independent refurbishers, they offer the highest confidence in component authenticity and restoration quality, often including direct manufacturer support for technical questions.

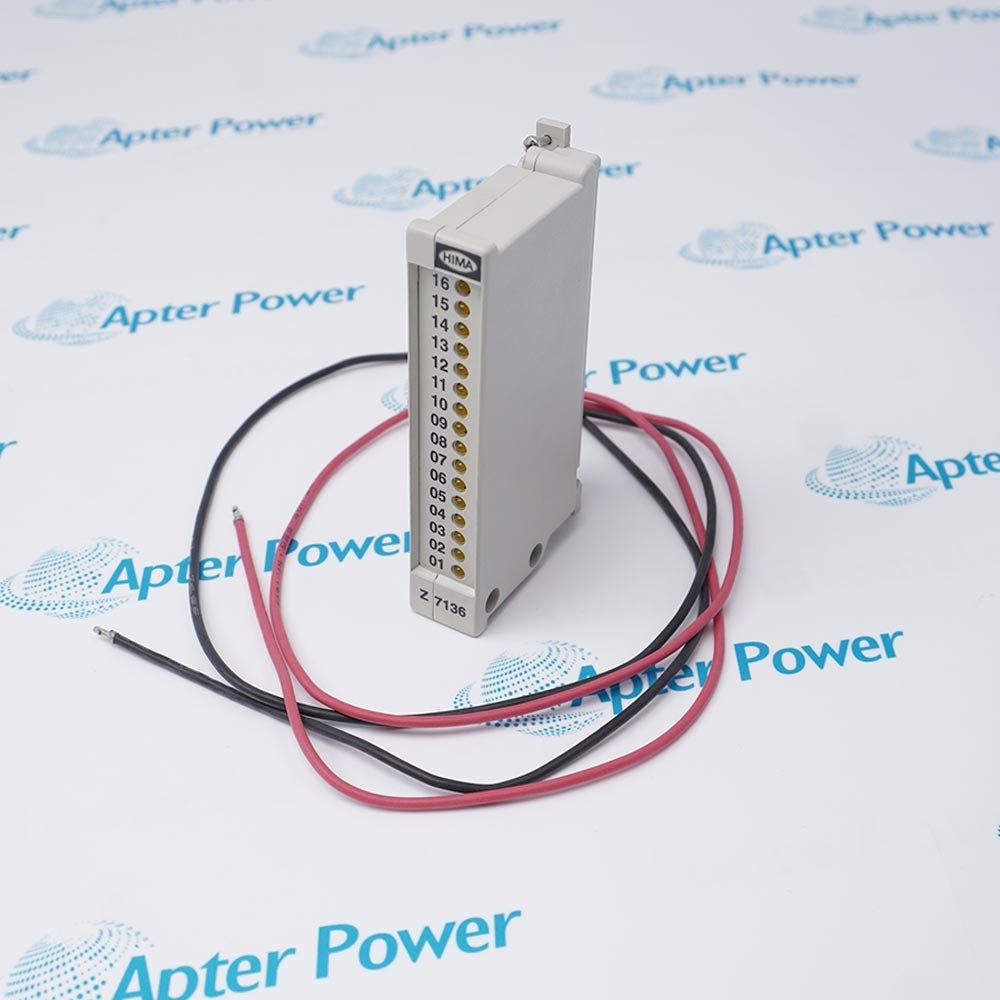

Established third-party suppliers specializing in industrial automation components represent another reliable sourcing avenue. Companies with decades of experience in safety system components understand the critical nature of Z7138 modules and implement rigorous quality controls to protect their reputation. These specialized vendors typically serve specific industries—petrochemical, power generation, or manufacturing—and build expertise around the equipment those sectors rely upon. Their technical staff can often provide application guidance beyond simple parts supply, helping engineers verify compatibility with existing systems or recommend configuration options. Suppliers such as Apter Power, which focus on automation and industrial spare parts, often maintain extensive inventories of refurbished safety system components and can provide technical consultation based on their experience across multiple installations. Industry trade associations and professional engineering networks offer valuable referrals to suppliers with proven track records in safety-critical component supply.

Online industrial marketplaces provide convenient access to multiple suppliers but require careful evaluation before purchase. Platforms connecting buyers with global sellers offer price comparison advantages and sometimes reveal availability when components seem scarce through traditional channels. However, the anonymity of online transactions increases risk—sellers may lack technical expertise, provide inadequate documentation, or offer components of questionable provenance. Reserve online marketplace purchases for situations where you can thoroughly vet seller credentials, request detailed component history, and secure payment protection mechanisms.

Evaluating Supplier Reliability

Credible suppliers demonstrate their reliability through verifiable business credentials and industry presence. Check for established business registration, physical facility addresses rather than mail drops, and longevity in the industrial automation sector—companies operating for ten or more years have weathered market cycles and built sustainable operations. Request customer references from facilities similar to yours and actually contact those references to discuss their experience with component quality, delivery reliability, and post-sale support. Professional suppliers maintain memberships in industry associations and hold quality certifications that require regular audits, providing external validation of their operational standards.

Warning signs indicate suppliers who may compromise component quality or fail to support purchases after delivery. Be cautious of prices significantly below market rates—extreme discounts often signal counterfeit components, inadequate refurbishment, or sellers liquidating questionable inventory. Suppliers unable or unwilling to provide component traceability documentation, including original manufacturing dates and operational history, lack the transparency quality transactions require. Pressure tactics demanding immediate purchase decisions, reluctance to answer technical questions, or refusal to provide written warranty terms all suggest suppliers prioritizing quick sales over customer success. Trust your instincts when supplier interactions feel rushed or evasive, and seek alternative sources rather than accepting unnecessary risk on safety-critical components.

Understanding Spare Parts Warranties

Warranty coverage for refurbished HIMA Z7138 components typically ranges from 90 days to one year, considerably shorter than the multi-year warranties accompanying new modules. This reduced coverage period reflects the reality that refurbished components have accumulated operational hours and may contain parts approaching their service life limits despite thorough testing. Reputable suppliers structure warranties to cover defects in refurbishment workmanship and component failures occurring under normal operating conditions, explicitly excluding damage from improper installation, environmental factors exceeding specifications, or modifications made after purchase. Understanding these limitations helps engineers set realistic expectations and plan appropriate risk mitigation strategies for critical safety systems.

Warranty terms for refurbished parts differ fundamentally from new component guarantees in both duration and scope. New Z7138 modules often include comprehensive manufacturer warranties covering materials, workmanship, and performance for two to three years, with some extended coverage options available. Refurbished warranties focus primarily on the restoration work performed, guaranteeing that testing procedures were properly executed and replaced components meet quality standards. Some suppliers offer tiered warranty options—basic coverage at lower prices or extended protection at premium rates—allowing facilities to balance cost considerations against risk tolerance. The absence of manufacturer backing means refurbished warranties rely entirely on the supplier’s financial stability and commitment to honoring claims, making supplier selection even more critical.

Effective warranty documentation should clearly specify covered failures, exclusion conditions, claim procedures, and remedies available when components fail. Examine whether warranties cover replacement parts only, or include labor costs and shipping expenses for return and redelivery. Verify the warranty start date—whether coverage begins at purchase, shipment, or installation—since this affects the actual protection period. Request written confirmation of warranty transferability if components might be relocated between facilities or systems. Documentation should identify specific testing protocols applied during refurbishment, providing baseline performance data against which future warranty claims can be evaluated. Suppliers offering vague warranty language or verbal-only assurances create unnecessary disputes when failures occur, whereas detailed written terms protect both parties through clear mutual understanding.

Maximizing Warranty Benefits

Warranty coverage typically requires professional installation following HIMA’s published guidelines and industry electrical standards. Suppliers may void warranties if modules are installed by unqualified personnel, connected to improperly grounded systems, or subjected to voltage levels outside specified ranges. Document your installation process with photographs, wiring diagrams, and commissioning test results that demonstrate compliance with manufacturer recommendations. Retain qualified electricians or automation specialists familiar with HIMA systems to perform installation work, ensuring proper handling of static-sensitive components and correct configuration of system parameters. Many warranty claims fail because facilities cannot prove installation followed proper procedures, making thorough documentation an essential protection measure.

Maintaining warranty validity requires adherence to preventive maintenance schedules and environmental controls that protect component longevity. Keep Z7138 modules within specified temperature and humidity ranges, ensuring control cabinet ventilation systems function properly and filters remain clean. Implement regular inspection routines that check connection tightness, verify absence of corrosion, and monitor diagnostic indicators for early warning signs of degradation. Document all maintenance activities with dated service logs that demonstrate consistent care throughout the warranty period. When failures occur, immediately cease operation and contact the supplier before attempting repairs, as unauthorized intervention typically voids coverage. Prompt failure notification, combined with preserved evidence of the failure mode, strengthens warranty claims and accelerates resolution processes.

Strategic Sourcing for Safety-Critical Components

Sourcing quality refurbished HIMA Z7138 components requires balancing multiple considerations to achieve both cost efficiency and operational reliability. Engineers must evaluate suppliers based on verifiable credentials, documented refurbishment processes, and transparent warranty terms rather than price alone. Authorized HIMA service centers offer the highest confidence in component authenticity and restoration quality, while established third-party specialists provide competitive alternatives when properly vetted through reference checks and quality certifications. Understanding warranty limitations specific to refurbished parts—including shorter coverage periods and installation requirements—enables realistic risk assessment and appropriate contingency planning for safety-critical systems.

The financial advantages of refurbished components become meaningful only when quality and support match operational demands. Prioritize suppliers who demonstrate technical competence through detailed testing documentation, maintain physical facilities for inspection, and provide responsive post-sale support when issues arise. Invest time in thorough supplier evaluation and warranty review upfront rather than addressing quality problems after installation compromises system reliability. For facilities managing safety instrumented systems, the modest time investment in careful sourcing pays dividends through reduced downtime risk, maintained safety certifications, and predictable equipment performance. Approach refurbished component procurement as a strategic decision that supports long-term operational excellence rather than simply a cost-reduction tactic.