In the fast-paced world of factory automation, even one tiny slip in sensor selection can slow a line, rack up costs, or damage fragile hardware. Proximity sensors matter because they spot an object-before or after-it touches anything else, letting engineers maintain contactless operation. Yet the sheer number of styles on the market means the right order can’t happen by simple catalog surfing.

This plain-language guide walks B2B engineers and buyers through the proximity sensor buying journey, step by step. Whether outfitting a brand-new cell or swapping out aging units, a trusted automation parts partner can match every probe to speed, range, and lifespan needs.

Understand the Role of Proximity Sensors in Automation

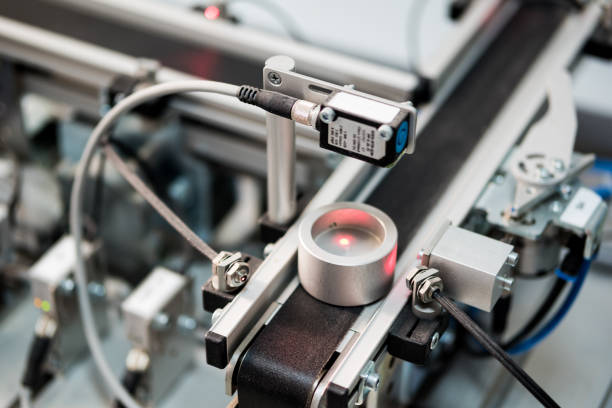

Proximity sensors appear everywhere: on belt conveyors, inside robotic wrists, beside packaging heads, and under safety guards. Because they signal without physical contact, parts stay fresh longer and lines react almost instantly to moving goods.

If you’re looking at proximity sensors, these three main types do the job:

- Inductive sensors for metal only

- Capacitive sensors for metal and most non-metal stuff

- Photoelectric sensors that use a light beam and work over long distances

In factories where clean rooms, quick responses, and precise readings matter, these sensors cut down on wear and tear, so machines run smoother.

Before you make a buy decision, talk with a seasoned automation parts supplier. They can match the right sensor to your application, whether that involves metal or plastic, how far away the target is, and what the surrounding conditions look like.

Identify Application Requirements Before You Buy

No sensor should go on the shelf until you first list what the job really needs. Smart engineers check these points to avoid headaches later:

- Target material: Use inductive for metal; go capacitive or photoelectric for plastic, liquid, or clear items.

- Detection range: Know the sweet spot, because some sensors sense within millimeters while others reach several meters.

- Environmental factors: Dust, moisture, shock, heat, or strong electrical fields can drift readings or burn out units.

- Mounting conditions: Tight spaces or odd angles may demand brackets, so plan how the sensor sits to keep results steady.

Check whether the control system accepts analog or digital inputs, and note if the switching logic is normally-open (NO) or normally-closed (NC).

Knowing these details will speed up your buy decision and stop costly mix-ups that halt production. A reliable automation parts supplier usually offers free application advice to help you through this check.

Compare the Pros and Cons of Sensor Types

You can pick from many different proximity sensors on the market today. The best choice depends on the job you need it to do. Here is a quick cheat sheet:

Inductive Proximity Sensors

These tough sensors create an electromagnetic field that locks on to metal targets.

Pros:

- Very resistant to dirt, dust, oil, and steam

- Long life with almost no upkeep

- Reacts to objects in microseconds

Cons:

- Handy only with metal, nothing else

- Detects at close range, usually under 10 mm

Capacitive Proximity Sensors

Capacitive sensors use an electric field to spot any item with a dielectric, such as water, grains, or plastic.

Capacitance Proximity Sensors

Capacitance sensors detect changes in electric fields, so they sense almost any material, from metal to plastic.

Pros:

- Detects a wide range of materials

- Adjustable sensitivity

- Ideal for non-contact level sensing

Cons:

- Prone to false triggering in humid or dusty environments

- Shorter lifespan under extreme conditions

Photoelectric Sensors

Photoelectric sensors use a focused light beam to check for objects, giving them the longest reach of any proximity style.

Pros:

- Suitable for long-distance applications

- Can detect transparent or reflective surfaces

- Flexible mounting options

Cons:

- Requires line-of-sight installation

- Sensitive to ambient light and dirt accumulation

Understanding these traits helps engineers pick the right option for their machines. When it’s time to buy, working with a trusted automation parts dealer ensures you get a sensor that stays reliable.

Evaluate Long-Term Costs and Integration

The true price of a sensor isn’t just the sticker cost. Installation effort, replacement frequency, downtime risk, and how well the sensor meshes with other parts all affect value.

Keep these points in mind:

- Durability: Pick a sensor with a high mean time between failures (MTBF), especially in busy operations that cycle nonstop.

- Energy efficiency: Sipping very little current, a good sensor still cuts power bills when hundreds are wired in.

- Maintenance needs: Models with self-cleaning glass or on-board health checks spend less time in the repair shop.

- Software compatibility: Sensors that speak IO-Link or similar protocols send clear status messages straight to the control room.

When you buy through a trusted automation-parts dealer, you usually get test reports, lifespan estimates, and hookup notes that expose hidden costs before they bite.

Collaborate with a Supplier That Adds Value

Even the best sensor will disappoint if the supply chain behind it stumbles. A dependable partner not only ships on time but also provides expert advice and service after the sale.

When picking a supplier, keep these points in mind:

- Inventory depth: Look for a stockroom that carries every style, size, and range you’ll need.

- Lead times: Next-day or same-day shipping can keep a stalled line moving.

- Customization: Some suppliers will add special cables, mounts, or label them to fit your line.

- Technical support: Phone, chat, or on-site help from engineers eases tricky installs and fixes.

- After-sales service: Easy returns, fast repairs, and hassle-free swaps protect your uptime and budget.

In fact, lots of engineers say the best bang for their proximity-sensor dollar comes not just from the sensor itself, but from the extra know-how their automation-parts supplier brings to the table.

Final Thoughts: Precision, Planning, and Partnerships

Picking the right proximity sensor is about more than reading the spec sheet. You need a mix of tech know-how, smart sourcing, and a clear view of how it will fit into daily operations. For B2B engineers and buyers, that means matching the sensor’s output to production targets while cutting risk and boosting efficiency.

Know your job, select the right sensor style, weigh integration and total cost, and lean on a trusted automation-parts partner. Do all that, and your sensor spend will pay off now and down the road.