Using Environmental, Social, and Governance (ESG) models presents particular difficulties for technical infrastructures. Data centers, manufacturing plants, research labs, and industrial complexes all consume significant energy, run under tight technical standards that might hinder sustainability projects, and use specialized equipment. Unlike traditional commercial spaces, technical facilities sometimes cannot simply lower resource usage without perhaps jeopardizing important purposes. Technical facilities may turn ESG concerns into opportunities for innovation and leadership by addressing unique environmental consequences, community partnerships, and governance systems.

Technical Infrastructure Optimization for Environmental Impact

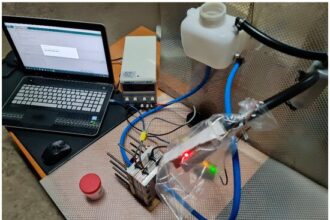

Usually, technical facilities have sophisticated infrastructure systems with a big impact on the surroundings. Good ESG performance starts with an all-encompassing evaluation of these systems and their resource use trends. You can set up advanced tracking and metering systems that give you detailed information on how energy, water, and materials move around the building. Real-time analytics find ways to save time and money that might be hidden in complicated working systems otherwise. Specialized ESG consulting teams with technical knowledge can help find ways to update buildings that are less harmful to the environment without changing how they work. Using modular methods for replacing equipment lets you do it in stages that fit with the cycles of capital expenditures. Power usage efficiency metrics that are specific to the equipment help put interventions in order of how much they might help.

Circular Resource Management for Technical Operations

Usually producing specific waste streams, technical facilities make use of commodities with major environmental impact. Circular resource strategies help to turn these difficulties into possibilities fit for ESG goals. Closed-loop water systems, which catch, treat, and recycle process water, dramatically lower consumption in water-intensive businesses. Programs in chemical management reduce the use of hazardous materials while guaranteeing the correct handling and disposal of required compounds. Programs for extending equipment lifetimes save embodied carbon while postponing capital costs. Partnerships in the supply chain make it possible to collect and reuse specialized parts that would otherwise end up in landfills. Material passport systems keep track of important resources throughout their entire lives, which makes them easier to recover in the end. Technical trash audits look for ways to keep things out of landfills and put them to good use again.

Community Integration and Stakeholder Engagement

Although they have major community implications through employment, environmental footprints, and local economic effects, technical facilities can have smaller public profiles than commercial enterprises. Careful community integration plans help to turn these interactions into ESG benefits. You can create open lines of contact wherein pertinent information on environmental performance and facility operations is shared with surrounding towns on a proactive basis. Partnerships between schools and neighborhood institutions build goodwill and talent pipelines. Working together with local officials to plan an emergency response makes the community safer and shows that the organization is responsible. Strategic local procurement programs boost economies in the area and cut down on pollution from transportation at the same time. Elements of a building’s design that improve its looks and reduce its visual effect show respect for the community context.

Specialized Governance for Technical Compliance and Responsibility

Technical facilities run under complicated regulatory systems needing specialized governance structures that combine technical compliance needs with environmental sustainability factors. Good governance systems create open reporting channels, well-defined roles, and responsible frameworks. Rather than compartmentalized initiatives, you can apply integrated management systems addressing environmental, health, safety, and quality criteria inside unified frameworks. Technical representation of cross-functional ESG committees guarantees that projects remain practically possible. Performance indicators connected to the pay system foster responsibility throughout the company. Mechanisms created especially for technical concerns by whistleblowers guarantee that such problems get the necessary attention before becoming more serious. Tracking legal requirements across borders, technology compliance monitoring tools guarantee constant performance despite geographic complexity.

Technology-Enabled Transparency and Reporting

Technical facilities create complicated performance data that has to be converted into relevant ESG reporting for several stakeholders. Digital solutions guarantee consistency and precision, so they help to translate. Specialized data management tools let you automatically gather and validate ESG data from several technical systems. From executives to community members, visualizing tools translate difficult technical facts into understandable forms for many audiences. Blockchain verification techniques guarantee data integrity through reporting procedures. Digital twin technologies allow scenario modeling to quantify possible ESG effects prior to choices on deployment. By means of these technology-enabled solutions, ESG reporting from a periodic burden becomes a tool for constant improvement that offers insightful analysis for both internal and external stakeholders, fostering trust and driving performance enhancements in all spheres, including environmental, social, and governance ones.

Conclusion

Making ESG work for technical facilities calls for specific strategies that respect their particular operating limitations and maximize their strengths. Even the most difficult technical facilities can make significant ESG progress by emphasizing infrastructure efficiency, circular resource management, community integration, specialized governance, and technology-enabled transparency. Technical facilities using these specialized approaches will find themselves in a good position to satisfy future needs while providing operational excellence as ESG standards change.