From food and beverage products to cosmetics and chemicals, one key part of the manufacturing process is getting liquid into containers accurately and efficiently. That’s where the filling machine comes in. These machines automate what would otherwise be a time-consuming, messy process, ensuring speed and consistency on production lines.

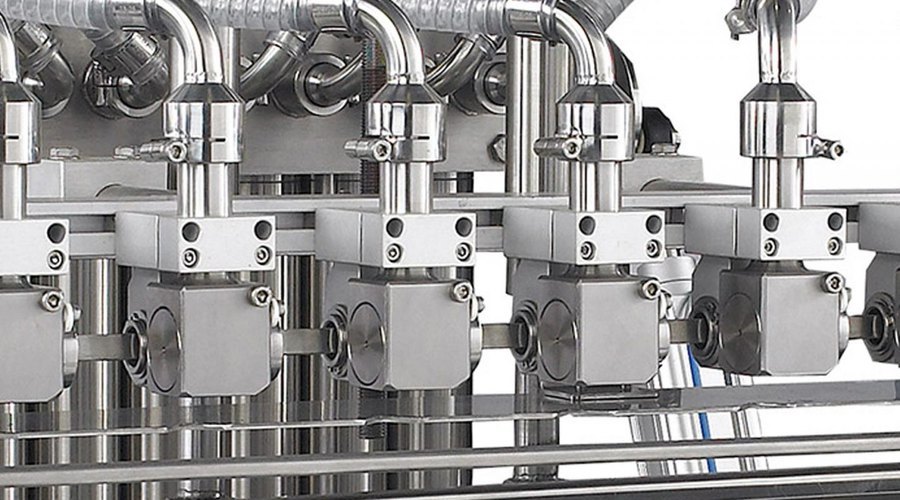

Among the different types of liquid fillers on the market, piston filling machines are known for their precision and versatility. If your operation deals with liquids of varying viscosities—like sauces, creams, oils, or gels—piston fillers might be the perfect fit. This article breaks down how these machines work and why they’re widely used across industries.

What Is a Filling Machine?

A filling machine is equipment designed to transfer a measured amount of liquid or semi-liquid product into a container—bottles, jars, tubes, and so on. These machines are essential for streamlining production, reducing waste, and maintaining consistent product quality.

There are several types of liquid fillers, including gravity fillers, overflow fillers, and vacuum fillers. But for thicker liquids or applications that require highly accurate volume control, piston filling machines are often the best choice. They use a mechanical piston to draw in product and then push it out into the container—providing both power and precision.

How Piston Filling Machines Work

At the core of a piston filling machine is a simple yet effective mechanism: a piston moves inside a cylinder to create suction and pressure. Here’s how it works:

- Suction Phase: As the piston retracts, it pulls liquid into the cylinder through a one-way inlet valve. This step draws a specific volume of product based on the size of the piston stroke.

- Dispense Phase: The piston then moves forward, pushing the liquid out through an outlet valve and into the container.

These machines often include adjustable settings to control how much product is dispensed during each cycle. That’s a major benefit when you’re filling a wide variety of container sizes or switching between products.

Because of their design, liquid piston fillers are especially effective with medium- to high-viscosity products—such as honey, peanut butter, shampoo, or lotions. They can also handle particulates, making them suitable for chunky sauces or products with bits of fruit or herbs.

Some piston fillers are manual or semi-automatic, suitable for small batches and startups. Others are fully automated and designed for integration into high-speed production lines.

Benefits of Piston Fillers

There are many reasons why manufacturers choose piston filling machines:

- Accuracy and Repeatability: Each cycle dispenses a fixed volume, reducing variation between containers. This ensures your labels (and your customers) match what’s inside the package.

- Versatility: Whether you’re working with thin oils or thick pastes, piston fillers can handle a wide range of viscosities without compromising accuracy.

- Cost-Effective: For businesses that don’t yet need a high-end, complex system, piston filling machines offer an affordable way to automate and improve consistency.

- Ease of Maintenance: These machines are mechanically simple, which makes cleaning and servicing them relatively straightforward. This is especially important in industries with strict sanitation requirements like food and pharmaceuticals.

- Scalability: You can start with a single-head unit and upgrade to multi-head piston filling machines as your business grows. That flexibility helps you match your equipment to your current and future output.

In short, piston fillers strike a balance between performance and practicality—making them a go-to solution for small to medium-sized producers and even some larger operations.

Where Piston Filling Machines Are Used

Thanks to their adaptability, piston filling machines are found across multiple industries. They’re used to fill:

- Food & Beverage: Jams, dressings, salsas, condiments, syrups

- Cosmetics: Creams, gels, lotions

- Pharmaceuticals: Ointments, gels, medicinal syrups

- Chemicals: Cleaning agents, oils, lubricants

Basically, if your product needs to be filled into a container—and especially if it’s thick, chunky, or sticky—a liquid piston filler is likely a smart choice.

Conclusion

When it comes to liquid packaging, the right filling machine can make all the difference in productivity, product quality, and cost savings. Piston fillers are a popular option because they offer reliable performance, flexibility, and ease of use for a wide variety of products.

Whether you’re a small business filling jars of homemade sauce or a growing company producing cosmetics at scale, a piston filling machine can help streamline your operations while maintaining high standards. By understanding how liquid piston fillers work, you’ll be better equipped to choose the right solution for your unique needs.