Introduction to Testing Electronic Components

Testing electronic components is often seen as a tedious step in the design and manufacturing process. However, it plays a crucial role in ensuring that devices function reliably and efficiently. Imagine the frustration of your smartphone suddenly malfunctioning or your favorite gadget failing because of a faulty component. With technology being an integral part of our daily lives, understanding the importance of testing these components becomes essential for both manufacturers and consumers.

From small circuit boards to complex systems, every electronic device relies on countless components working harmoniously. But how can we be sure they’ll perform as expected? The answer lies in rigorous testing methods that not only identify potential issues but also enhance overall product quality. This blog will delve into why testing electronic components should never be overlooked, explore common pitfalls associated with neglecting this vital procedure, and highlight various testing techniques available today. Join us as we uncover the significance behind this critical aspect of electronics!

The Significance of Testing Electronic Components

Testing electronic components is crucial for various reasons. It ensures that devices function as intended, preventing potential failures in critical applications.

Regular testing can save both time and money. Identifying issues early allows for prompt resolutions, reducing costly repairs or replacements later on.

Moreover, safety is a significant factor. Faulty components can lead to hazardous situations, including electrical fires or equipment damage. Proper testing minimizes these risks.

In industries where precision matters—like aerospace or healthcare—testing becomes even more vital. Components must meet strict standards to ensure reliability under demanding conditions.

Additionally, thorough evaluation of components enhances product quality and customer satisfaction. A well-tested device builds trust among consumers and reinforces brand reputation in the market.

Common Issues with Electronic Components

Electronic components can face a variety of issues that hinder performance. One common problem is overheating. Excessive heat can damage sensitive parts, leading to failure.

Another frequent issue involves incorrect voltage levels. Components may not function properly if exposed to voltages outside their specified range. This can lead to malfunctions or even complete breakdowns.

Additionally, physical damage is a concern. Dropping or mishandling devices can cause cracks or disconnections within the circuitry.

Dirt and corrosion also play significant roles in component failures. Contaminants on connectors and circuit boards impede electrical flow, resulting in unreliable operation.

Aging components pose risks too. Over time, materials degrade, which affects efficiency and increases the likelihood of faults occurring unexpectedly. Addressing these issues through regular testing electronic practices helps maintain reliability and extend lifespan.

Different Methods of Testing Electronic Components

Testing electronic components involves various methods, each tailored to specific needs.

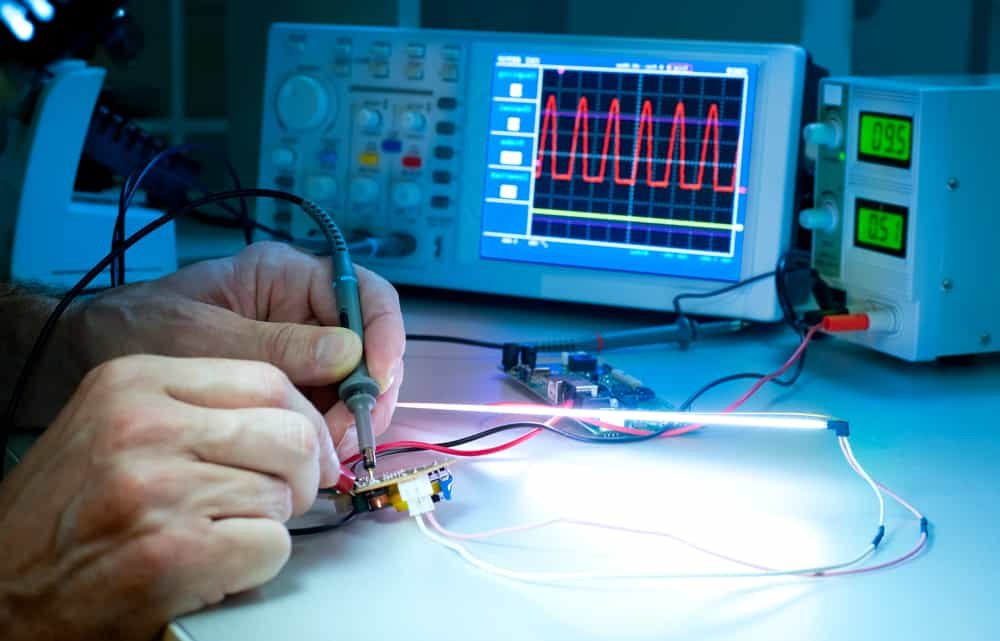

Visual inspection is often the first step. Technicians examine parts for physical damage, corrosion, or incorrect labeling. This can quickly identify obvious issues.

Next comes functional testing. Here, components are assessed within a circuit to ensure they perform as intended under normal conditions. This method highlights how well the component integrates into an overall system.

Another popular technique is automated test equipment (ATE). These systems run multiple tests simultaneously and provide detailed data on performance metrics. They enhance accuracy and speed in large-scale production environments.

For more intricate evaluations, engineers may use oscilloscopes or multimeters to measure voltage levels and signal integrity precisely. Such tools allow for deep dives into a component’s behavior during operation.

Environmental testing subjects components to extreme temperatures or humidity levels to gauge their durability under stress—essential for ensuring long-term reliability.

Benefits of Regularly Testing Electronic Components

Regularly testing electronic components is crucial for maintaining their functionality. It helps identify potential issues before they escalate into more significant problems. By catching these early, you can save time and resources.

Testing also ensures that products meet quality standards. This enhances reliability and boosts customer satisfaction. When customers trust your product’s performance, it strengthens brand loyalty.

Additionally, frequent checks can extend the lifespan of components. By addressing minor faults promptly, you reduce wear and tear on devices over time.

Another benefit is improved safety. Faulty components can lead to hazardous situations like electrical fires or equipment failures. Regular testing mitigates these risks significantly.

Documenting test results creates a valuable record for future reference. This data aids in decision-making regarding upgrades or replacements as technology evolves.

Conclusion

Testing electronic components is not just a step in the manufacturing process; it’s a crucial practice that ensures reliability and functionality. By identifying potential issues early, manufacturers can save costs and improve product quality. Regular testing reduces the risk of failures in critical applications, maintaining safety standards for both consumers and industries.

With advancements in technology, various methods are available to assess component performance effectively. Whether through visual inspection or sophisticated automated systems, staying proactive about testing can significantly enhance efficiency.

Prioritizing regular checks helps foster trust among customers while ensuring that products meet industry standards. It creates a robust foundation for innovation as companies push toward more complex technologies.

As we continue to rely on electronic devices in our daily lives, embracing thorough testing practices will remain essential for progress and safety across all sectors.