In the world of textiles, quality isn’t just about how a fabric looks or feels—it’s fundamentally about how it performs under stress. At the heart of this critical assessment lies a piece of indispensable equipment: the fabric tensile tester. This sophisticated machine does much more than just pull fabric until it breaks; it provides the scientific data that ensures safety, durability, and performance across countless industries, from fashion and footwear to automotive and aerospace.

Modern tensile testers, like the SmartPull Fabric Tensile Tester, represent a leap forward from basic strength measurement. They are intelligent systems that can determine a material’s maximum breaking force, its elongation, its elastic properties, and even its behavior under specific, controlled loads. This guide will explore the technology, operation, and vital importance of these machines in today’s manufacturing landscape.

How a Modern Fabric Tensile Tester Works

At its core, tensile testing is a method to measure a fabric’s response when pulled in one direction. The process determines both the force needed to break the fabric and how much it stretches before failure. These two data points—strength and elongation—are foundational for evaluating quality, durability, and suitability for end use.

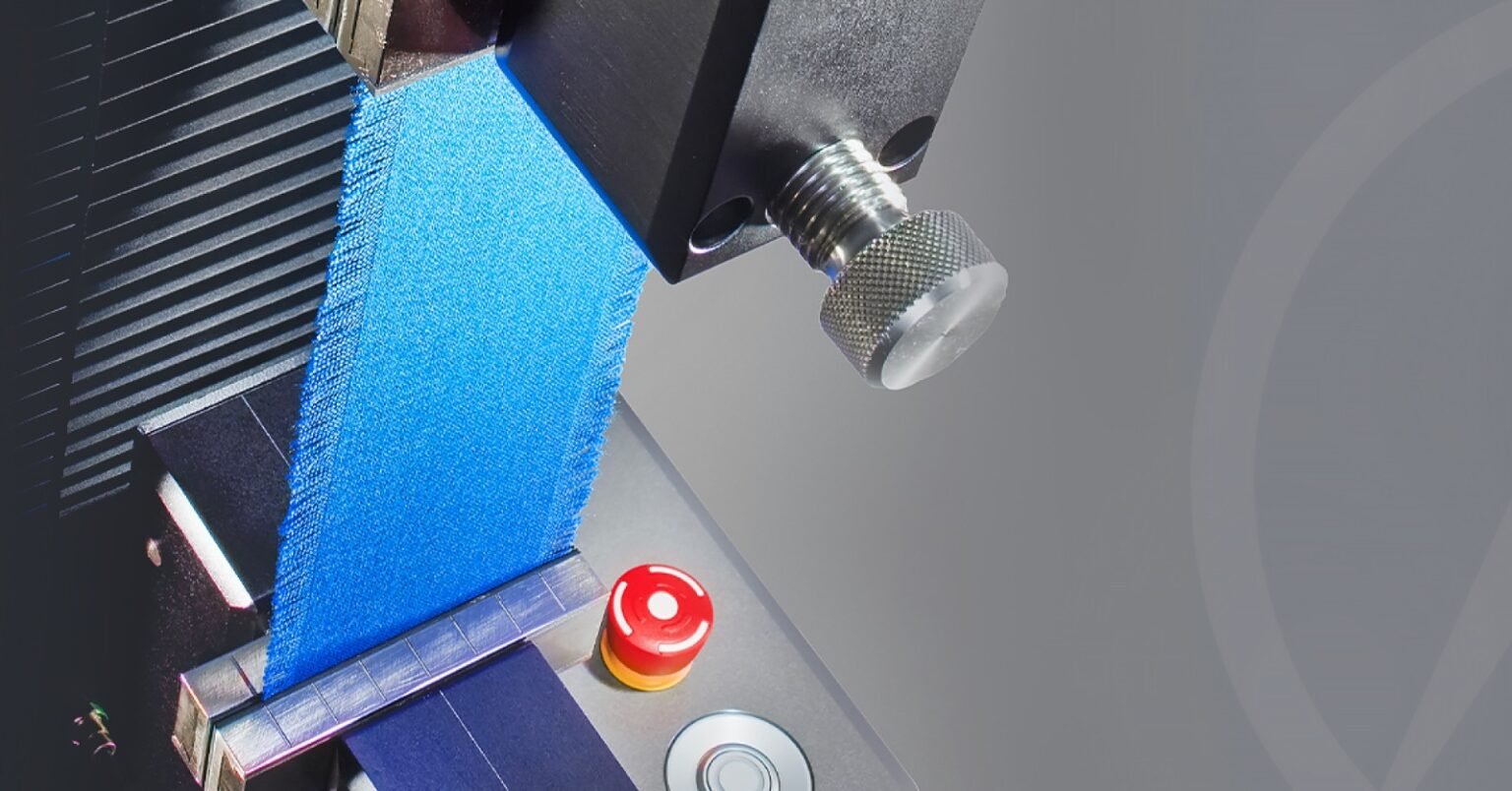

The test is performed by a Universal Testing Machine (UTM), or tensile tester, which applies a steady, controlled pulling force to a precisely cut fabric sample. The sample is held by specialized fixtures or clamps. As the machine’s crosshead moves, it stretches the sample while integrated sensors collect real-time data on the applied force and the resulting displacement.

The SmartPull Advantage: Precision Engineering

The SmartPull Fabric Tensile Tester exemplifies modern precision in this field. Its operation is built on a foundation of high-accuracy components:

- Power & Drive System: It utilizes an AC servo motor combined with ball screws to generate exceptionally steady and precisely controlled pulling power. This system minimizes measurement error to within 1%, guaranteeing highly accurate and repeatable test results.

- Smart Sensing: At the heart of the measurement are high-precision load cells. These devices use strain gauge transducers and the Wheatstone Bridge principle to convert mechanical force into exact electrical signals. Simultaneously, displacement transducers measure the sample’s stretch in real time.

- Intelligent Protection: Safety is engineered into the system. The tester can intelligently detect excessive torque and displacement and features automatic travel limits to protect both the machine and the operator from overload scenarios.

Key Features of an Advanced Tensile Tester

When selecting a fabric tensile tester, several features distinguish a basic machine from a comprehensive quality control partner.

- Multi-Functional Testing: A versatile tester like the SmartPull is not limited to simple tension. It can be configured for a wide range of tests including top-breaking, tearing, shearing, bending, compression, and peeling, making it a single solution for many lab needs.

- Comprehensive, User-Friendly Software: The software is the brain of the operation. A powerful system displays and records a full suite of data—tension, elongation, displacement, maximum force, and stress-strain curves—in real time. This allows for deep analysis and precise material evaluation. The SmartPull’s software is designed for intuitive operation, guiding users through setup and compliance with global standards.

- Compliance with International Standards: Reliability means meeting global benchmarks. Advanced testers are built to comply with a vast array of international standards, such as:

- ISO Standards: ISO 13934-1/2 (fabric tensile), ISO 13937-2/3 (tear), ISO 3377-2 (leather tear).

- ASTM Standards: ASTM D5034 (Grab Test), ASTM D5035 (Strip Test), ASTM D5587.

- GB (Chinese National) Standards: GB/T 3923.1, GB/T 3917.2, among others.

- Modular & Robust Design: A user-friendly design includes features like a side-cutting structure to save space and quick-swap grippers and fixtures. This modularity allows labs to switch between different test types (e.g., fabric, yarn, leather) rapidly without needing to replace core sensors. The machine’s robust construction, often involving cast iron or steel key components, ensures long-term stability and durability.

The Tensile Testing Process: A Step-by-Step Overview

Conducting a standardized tensile test involves careful preparation, precise execution, and accurate data analysis.

- Preparation & Setup

- Sample Preparation: Fabric samples are cut to specific dimensions (e.g., 25mm x 100mm, 50mm x 75mm) as dictated by the chosen test standard.

- Machine Calibration: Before testing, both force and displacement speed must be calibrated. Force is often calibrated using certified standard weights or a tensile transducer, while speed is verified by measuring the actual travel distance of the fixtures over a timed interval. This ensures the tester’s error remains within a tight ±1% tolerance.

- Fixture Selection: The appropriate clamps or fixtures (e.g., for grab test, strip test, leather tear) are installed on the machine.

- Running the Test

- The sample is securely placed in the upper and lower clamps.

- Test parameters (speed, limit stops, standard method) are set in the software.

- The test begins, and the machine’s crosshead moves at a constant speed (typically between 1mm/min to 500mm/min), applying tension to the sample.

- Sensors gather continuous force and displacement data until the sample fractures.

- Data Analysis & Reporting

- The software automatically generates key results: maximum tensile strength (breaking force), elongation at break, and often a full stress-strain curve.

- This curve is a critical visual tool, showing the fabric’s behavior from initial stretching through yield point and ultimate failure.

- Data can be compiled into standardized reports for quality records or compliance certification.

Technical Specifications at a Glance: The SmartPull Example

| Feature | Specification |

|---|---|

| Test Capacity | 250 kg (with a 500 kg deformation limit) |

| Max Travel | 800 mm (without fixtures) |

| Traverse Speed Range | 1 mm/min ~ 500 mm/min |

| Speed Accuracy | ≤ ±1% |

| Force Accuracy | ≤ ±1% |

| Travel Accuracy | ≤ ±1% |

| Power Supply | 220V, 50Hz/60Hz |

| Dimensions (DxWxH) | 630 x 460 x 1470 mm |

| Weight | Approx. 90 kg |

Applications Across Industries

The data from a fabric tensile tester is vital for R&D, material selection, quality control, and failure analysis.

- Textile Manufacturing: Verifying that woven, knitted, and non-woven fabrics meet strength requirements for apparel, home textiles, and technical textiles.

- Footwear & Leather Goods: Testing the tensile and tear strength of leather, synthetics, and component materials to ensure product longevity.

- Academic & Research Institutions: Studying new fabric blends, composites, and manufacturing processes to advance material science.

- Quality Assurance Labs: Providing certification that materials from suppliers or final products comply with contractual and safety standards.

What Users Are Saying

Feedback highlights real-world value. A textile factory in Spain noted the “excellent service” and reliable 250kg-capacity machine, while a textile university in Colombia praised the tester’s “nice design” and the fact that “the tensile test results are very reliable.”

Choosing the Right Tensile Tester for Your Needs

Investing in a fabric tensile tester is a significant decision. Consider these factors:

- Required Force Capacity: Match the machine’s capacity (e.g., 250kg, 500kg) to the strongest materials you need to test.

- Standards Compliance: Ensure the machine and its available fixtures are certified for the specific international or industry standards your work demands.

- Software Capabilities: Look for intuitive, powerful software that manages data effectively and can grow with your testing needs.

- Versatility & Upgradability: A modular design that allows you to add new fixtures for different tests (yarn, peeling, etc.) protects your long-term investment.

- Support & Service: Choose a provider known for professional support, training, and calibration services, as highlighted by users of ChiuVention’s equipment.

The Bottom Line

A modern fabric tensile tester is far more than a simple strength gauge. It is a precision data acquisition system that translates physical material properties into actionable intelligence. In an era where product integrity is non-negotiable, this technology empowers manufacturers, researchers, and quality professionals to build trust, ensure safety, and drive innovation—one precise test at a time. By understanding the technology and process behind tensile testing, you can make informed decisions that uphold the highest standards of quality and performance.