— An In-Depth Technical Insight for Modern Manufacturing and Water Treatment Industries

- Key advantages of polypropylene include:

- ✔ Excellent chemical resistance

- ✔ High temperature tolerance

- ✔ No leaching risks

- ✔ Low cost with high durability

- ✔ Environmentally friendly

- 1. Larger surface area

- 2. Higher flow rate

- 3. Lower pressure drop

- 4. Longer service life

- 5. Improved filtration accuracy

- ✔ Accurate and stable micron ratings

- ✔ High dirt-holding capacity

- ✔ Low extractables

- ✔ High flow rates

- ✔ Integrity testing compatibility

- Major industrial applications include:

- ✔ PP Pleated Filter Cartridges vs. Melt-Blown Filters

- ✔ PP Pleated Filters vs. String-Wound Filters

- ✔ PP Pleated Filters vs. Ceramic Filters

- 1. Longer Service Life

- 2. Lower Energy Consumption

- 3. Protection of Expensive Downstream Equipment

- 4. Reduced Maintenance Costs

- 5. Better Process Stability and Product Quality

- 1. Micron Rating

- 2. Length and Dimensions

- 3. End Cap Type

- 4. Flow Rate Requirements

- 5. Chemical Compatibility

- 6. Operating Temperature and Pressure

- 7. Certification Requirements

- ✔ Lower energy consumption reduces CO₂ emissions

- ✔ Long service life reduces waste generation

- ✔ Recyclable polypropylene supports circular production

- ✔ High filtration efficiency reduces chemical usage in wastewater treatment

- ✔ Improved process stability reduces defective product output

- 1. Electronics Manufacturing Plant – Singapore

- 2. Food & Beverage Factory – Poland

- 3. Power Plant – Middle East

Industrial water filtration has become one of the most important pillars of modern manufacturing. From food processing lines requiring microbiological safety to power plants needing ultra-clean process water, every sector depends on filtration solutions that are efficient, stable, and cost-effective. Among the many filtration technologies available today, PP pleated filter cartridges stand out as one of the most widely adopted solutions for industrial filtration systems worldwide.

In recent years, as industries place greater emphasis on sustainability, production efficiency, and water quality consistency, PP pleated filters have become the preferred choice for companies seeking high-performance filtration without excessive operating costs. But what exactly gives these cartridges such an advantage? Why are so many engineers and plant managers replacing older filtration methods with PP pleated filters?

This article explores the science, engineering logic, and industry applications behind PP pleated filter cartridges, explaining why they are considered the most reliable and cost-effective filtration choice for industrial water treatment today.

1. Understanding the Role of Industrial Water Filtration

Water is one of the most universally used resources in industrial operations. However, industrial-grade water must meet specific purity requirements depending on the application.

Industries depend on filtration to solve several critical problems:

- Removing suspended particles

- Preventing equipment wear caused by impurities

- Protecting downstream membrane systems (RO, UF, NF)

- Ensuring consistency in production quality

- Meeting safety and compliance standards

- Stabilizing the performance of chemical and biological processes

Without proper filtration, factories experience escalating maintenance costs, premature membrane fouling, equipment damage, production delays, and inconsistent output quality. Therefore, the filtration method selected has a direct impact on the overall operational efficiency of an industrial facility.

PP pleated filter cartridges, with their precise filtration capability and long service life, provide the balance between high performance and low operational cost that industries require.

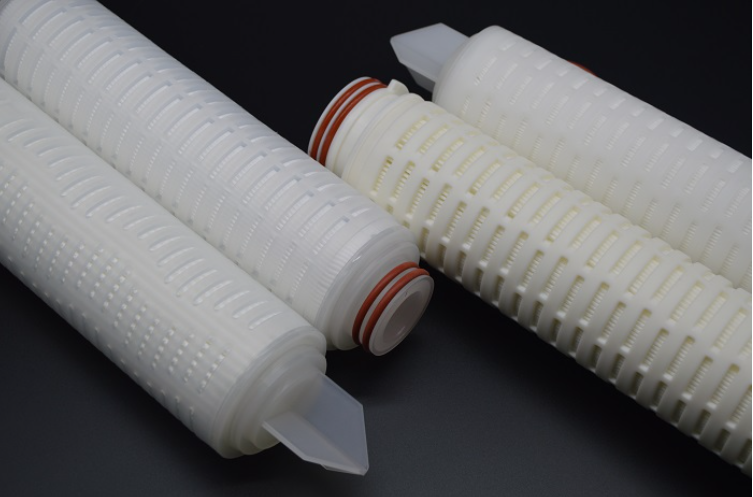

2. What Are PP Pleated Filter Cartridges?

PP pleated filter cartridges are depth-style filter cartridges made from polypropylene (PP) media that is folded into a pleated structure. The design maximizes the surface area of the filter, resulting in significantly higher flow rates and lower pressure drop compared to non-pleated filters.

A typical PP pleated filter consists of:

- Polypropylene filtration media (the pleated layers)

- PP support layers for structural strength

- PP inner core and outer cage

- Thermal bonding ensuring chemical purity with no adhesives

- Various end-cap types to fit different housings (DOE, 222, 226, fin, flat, etc.)

This structure offers high dirt-holding capacity, excellent particle retention, and outstanding compatibility with a wide range of industrial fluids.

Because every component is made of polypropylene, PP pleated filters are:

- Chemically inert

- Compatible with acids, alkalis, solvents, and oxidants

- Free from adhesives or glue

- Suitable for high-purity applications

These characteristics make PP pleated filters ideal for demanding industrial environments where stability and consistency are essential.

3. Why PP Material Matters: The Advantages of Polypropylene

Polypropylene is one of the most widely used materials in industrial filtration due to its excellent mechanical and chemical properties. PP pleated filter cartridges enjoy significant advantages because the filtration media and support structure are all PP-based.

Key advantages of polypropylene include:

✔ Excellent chemical resistance

PP is compatible with strong acids, strong alkalis, oxidizing agents, and a wide range of industrial chemicals.

This makes PP pleated cartridges suitable for:

- Chemical production

- Electroplating wastewater

- Power plant water systems

- Industrial wastewater treatment

- Cooling towers

✔ High temperature tolerance

PP can withstand up to 80–90°C in continuous operation environments, making it suitable for many industrial liquid filtration applications.

✔ No leaching risks

High-purity PP materials prevent unwanted chemical extraction, ensuring the filtered water remains safe and uncontaminated.

✔ Low cost with high durability

PP delivers the perfect balance between mechanical strength and economic efficiency, providing long service life without high replacement cost.

✔ Environmentally friendly

PP is 100% recyclable, which aligns with global initiatives for sustainable manufacturing practices.

4. The Engineering Advantage: Why Pleated Structure Is Superior

The pleated design is one of the biggest engineering advantages of PP filter cartridges.

By folding the filtration media into multiple pleats, the filter gains:

1. Larger surface area

A pleated structure can increase effective filtration area by 5–10 times compared to cylindrical filters.

2. Higher flow rate

More surface area means fluid can pass through more quickly without increasing pressure.

3. Lower pressure drop

Reducing system pressure significantly lowers energy consumption and protects pumps and RO membranes.

4. Longer service life

The increased area allows the filter to capture more particles before clogging.

5. Improved filtration accuracy

Pleated media ensures uniform pore distribution, enabling consistent retention of particles down to micron or sub-micron levels.

In other words, pleated filters offer superior efficiency and cost-effectiveness, making them ideal for high-volume industrial filtration.

5. Filtration Performance: Why PP Pleated Filters Excel in Industrial Use

PP pleated filter cartridges deliver a range of performance advantages that engineers consistently praise.

✔ Accurate and stable micron ratings

Available in:

- 0.1 μm

- 0.2 μm

- 0.45 μm

- 1 μm

- 5 μm

- 10 μm

- 20 μm

- 50 μm

This flexibility allows customization based on system requirements.

✔ High dirt-holding capacity

Pleated structure allows the filter to capture more particles before reaching its maximum differential pressure.

✔ Low extractables

Pure polypropylene construction minimizes contamination and ensures compliance with strict industrial standards.

✔ High flow rates

Engineers often choose PP pleated filters for industries where large volumes of water must be processed efficiently.

✔ Integrity testing compatibility

Many PP pleated filters can be integrity-tested, which is crucial in high-purity applications.

6. Industrial Applications: Where PP Pleated Filters Perform Best

Because of their versatility and stability, PP pleated filter cartridges are used across dozens of industrial sectors.

They are particularly dominant in systems where both high flow rate and precise filtration are required.

Major industrial applications include:

- Reverse osmosis (RO) prefiltration

- Ultrapure water (UPW) systems

- Power plant boiler feedwater

- Petrochemical and chemical processing

- Electronics and semiconductor manufacturing

- Food and beverage production

- Pharmaceutical water systems

- Cooling water filtration

- Electroplating and surface treatment

- Industrial wastewater recycling

In each of these industries, PP pleated filters help protect equipment, stabilize product quality, and reduce maintenance costs.

7. Comparing PP Pleated Filter Cartridges with Other Common Filtration Technologies

To understand why PP pleated filter cartridges have become the preferred choice in industrial applications, it is useful to compare them with traditional filtration options. Each filter type offers certain strengths, but PP pleated cartridges often outperform them in overall efficiency, cost, and durability.

✔ PP Pleated Filter Cartridges vs. Melt-Blown Filters

Melt-blown filters are widely used because they are inexpensive and simple in structure. However, they are limited in performance when compared to pleated designs.

Melt-Blown Filters:

- Lower filtration area

- Faster clogging

- Higher replacement frequency

- Lower precision

- Higher long-term cost

PP Pleated Filters:

- 5–10× filtration area

- Longer service life

- Higher flow rate

- Stable and accurate micron ratings

- Better for heavy-duty industrial use

Verdict:

Melt-blown filters may be suitable for low-budget or low-demand applications, but for industrial water filtration, pleated filters offer far superior performance and significantly reduce long-term operating costs.

✔ PP Pleated Filters vs. String-Wound Filters

String-wound filters are known for their strength and ability to handle high dirt loads. However, they lack the precision that industries now require.

String-Wound Filters:

- Inconsistent pore size

- Particle bypass risk

- Less suitable for high-purity processes

- Higher labor cost due to frequent replacement

PP Pleated Filters:

- Uniform pore distribution

- Reliable, absolute-rated filtration

- Better particle retention

- More suitable for prefiltration before RO

Verdict:

String-wound filters still play a role in low-precision, high-contaminant environments, but for consistency and high-quality output, PP pleated filters are clearly superior.

✔ PP Pleated Filters vs. Ceramic Filters

Ceramic filters are known for durability but come with several limitations:

Ceramic Filters:

- High cost

- Fragile and difficult to handle

- Heavy and unsuitable for compact systems

- Slow flow rate

PP Pleated Filters:

- Lightweight and versatile

- High flow rate

- Lower cost

- Easy installation and replacement

Verdict:

Ceramic filters are suitable for specialized applications, but PP pleated filters provide a much more flexible and economical solution for industrial water treatment.

8. Economic Advantages: How PP Pleated Cartridges Reduce Filtration Costs

Industrial filtration is not just a technical requirement; it is also a major operational expense. The choice of filtration technology directly impacts energy consumption, maintenance frequency, downtime, and long-term total cost of ownership (TCO). PP pleated filter cartridges help reduce costs in several ways:

1. Longer Service Life

Because of their extended surface area and superior dirt-holding capacity, PP pleated cartridges require fewer replacements. This reduces:

- Labor costs

- Spare parts inventory

- System downtime

2. Lower Energy Consumption

PP pleated filters maintain lower pressure drop, which means pumps consume less energy to maintain flow. Over thousands of operating hours, this reduction has a significant financial impact.

3. Protection of Expensive Downstream Equipment

RO membranes, UV systems, heat exchangers, and dosing pumps are costly to replace. High-efficiency prefiltration dramatically increases their lifespan.

4. Reduced Maintenance Costs

With fewer blockages, fewer emergency shutdowns, and fewer unexpected failures, facilities experience much smoother operations.

5. Better Process Stability and Product Quality

In industries such as beverage production, pharmaceuticals, and electronics manufacturing, unstable water quality can cause expensive production losses. PP pleated filters help maintain consistency.

9. How to Select the Right PP Pleated Filter Cartridge

Choosing the right PP pleated filter cartridge is crucial in maximizing filtration efficiency and preventing system failures. Engineers should consider several key specifications:

1. Micron Rating

The most important factor. Depending on the application:

- 0.1–0.45 μm → High-purity water, RO security filtration

- 1–5 μm → Industrial process water

- 10–20 μm → General particle removal

- 50 μm+ → Prefiltration for high-dirt systems

2. Length and Dimensions

Common lengths include:

- 5”

- 10”

- 20”

- 30”

- 40”

Length affects overall surface area and dirt-holding capacity.

3. End Cap Type

To ensure compatibility with the housing, engineers select:

- DOE (Double open end)

- 222 / 226 O-ring

- Flat / Fin

O-ring materials (EPDM, NBR, Viton) should match the chemical environment.

4. Flow Rate Requirements

Flow rate should match pump capacity and downstream equipment requirements. PP pleated filters are ideal for high-flow systems because of their large surface area.

5. Chemical Compatibility

Because PP resists most acids and alkalis, it is usually compatible. However, engineers should verify compatibility with specialty solvents.

6. Operating Temperature and Pressure

Most PP pleated filters operate at:

- ≤ 80–90°C

- ≤ 4.0 bar differential pressure

7. Certification Requirements

For industries like electronics or pharmaceuticals, filters may require:

- FDA compliance

- NSF/ANSI certification

- ISO standard manufacturing

- Validation documentation

10. Why PP Pleated Filters Support Sustainable Manufacturing

As environmental regulations become stricter, industrial facilities must adopt filtration technologies that reduce waste, energy use, and environmental impact. PP pleated filters support sustainability in several ways:

✔ Lower energy consumption reduces CO₂ emissions

✔ Long service life reduces waste generation

✔ Recyclable polypropylene supports circular production

✔ High filtration efficiency reduces chemical usage in wastewater treatment

✔ Improved process stability reduces defective product output

For facilities pursuing ISO 14001 environmental management certifications, PP pleated filter cartridges provide a measurable improvement in sustainability metrics.

Industrial brands that aim for greener manufacturing increasingly turn to experienced filtration suppliers such as Econe Filtration, whose PP pleated filter cartridges offer both high-efficiency performance and environmentally responsible design. By incorporating advanced pleated filtration into their water treatment systems, factories not only enhance operational efficiency but also take meaningful steps toward long-term sustainability.

11. Real-World Case Studies: How Industries Benefit from PP Pleated Filters

1. Electronics Manufacturing Plant – Singapore

A facility producing semiconductor components struggled with inconsistent water quality in its UPW system. After replacing melt-blown filters with PP pleated cartridges, the plant achieved:

- 40% reduction in filter replacement frequency

- 25% increase in RO membrane lifespan

- Improved product reliability

2. Food & Beverage Factory – Poland

A bottled beverage manufacturer needed stable, microbiologically safe process water. The switch to PP pleated filters resulted in:

- Improved water clarity

- Reduced sediment load in final product

- A 20% reduction in maintenance downtime

3. Power Plant – Middle East

A large thermal power plant using seawater desalination improved prefiltration by replacing string-wound filters with PP pleated cartridges:

- Annual savings of over $50,000

- Lower pressure drop across the system

- Stable boiler feedwater quality

12. Final Conclusion: Why PP Pleated Filter Cartridges Are the Best Choice

After analyzing filtration performance, cost efficiency, engineering advantages, and real-world results, the conclusion is clear:

PP pleated filter cartridges deliver the best balance of performance, precision, durability, cost, and sustainability for industrial water treatment.

They excel in:

- High-purity filtration

- High-flow industrial systems

- RO prefiltration

- Chemical and process water applications

- Food, beverage, and pharmaceutical production

Their ability to maintain stable quality while reducing operational costs makes them the top choice for modern industries seeking reliable and scalable filtration solutions.