If the battery is the “heart” of an electric vehicle, then the cathode material is undoubtedly the key component of this “heart” that determines the energy density and voltage. Different cathode materials, like “energy carriers” with different characteristics, directly shape the range, acceleration performance and even cost of electric vehicles.

This article will unfold a technical panorama of power battery cathode materials to see how this “ultimate showdown” between performance and cost is staged, from the familiar lithium iron phosphate (LFP) to the imaginative solid-state battery.

Importance of positive electrode materials: the “ceiling” of battery performance

In simple terms, the working principle of the battery is that lithium ions “move” back and forth between the positive and negative electrodes. The positive electrode is like the “starting point” and “temporary residence” of lithium ions. Its material properties directly determine how many lithium ions the battery can hold (energy density) and the “speed” of lithium ion movement (power performance and voltage). Therefore, the performance of the positive electrode material largely determines the overall performance of the battery.

Classic materials: Aqueous lithium-ion battery positive electrode

In the world of liquid lithium-ion batteries, positive electrode materials can be roughly divided into the following camps, each with its own characteristics and focus:

Lithium iron phosphate (LFP): stable development:

Lithium iron phosphate can be said to be one of the most popular cathode materials in recent years. Its advantages are high safety (good thermal stability, not prone to thermal runaway), long cycle life, and relatively low cost. But its relatively low energy density is its shortcoming. However, through technologies such as CTP (Cell to Pack), the energy density of LFP battery packs is also constantly improving.

Ternary materials (NCM/NCA): pursuit of high performance

Ternary materials usually refer to nickel cobalt manganese oxide (NCM) and nickel cobalt aluminum oxide (NCA). These materials are characterized by high energy density, which means that electric vehicles equipped with ternary batteries can often achieve longer driving range. In order to further improve energy density, the industry is also actively developing high-nickel ternary. However, compared with LFP, ternary materials are usually more expensive and their safety is relatively more challenging.

Lithium manganese oxide (LMO): Balanced cost performance

The advantages of lithium manganese oxide are low cost and good rate performance (relatively fast charge and discharge speed), but there are some shortcomings in cycle life and high temperature performance, and the energy density is also between LFP and ternary.

In order to more intuitively understand the characteristics of these mainstream positive electrode materials, the following table is compared:

| Material type | Energy density (Wh/kg) | Cycle life (times) | Safety | Cost | Main applications |

| Lithium iron phosphate (LFP) | 140-180 | > 3000 | Very good | low | Low-end and mid-range electric vehicles, energy storage |

| Ternary (NCM523) | 180-230 | > 1500 | Good | medium | Mid-end electric vehicles |

| Ternary (NCM811) | 220-300 | > 1000 | High challenge | high | Mid-end and high-end electric vehicles |

| Lithium manganese oxide (LMO) | 100-160 | 500-1000 | Good | low | Some A00-class electric vehicles, energy storage |

| Solid-state battery (speculation) | 300-500+ | 未知 | Very high | high/waiting to be reduced | Future high-end electric vehicles |

| Lithium manganese iron phosphate (LMFP) | 180-230 | > 2000 | Good | medium | Expected to be used in mid-end and high-end electric vehicles |

(Note: The above data are approximate ranges, and the actual values will vary depending on the specific process and formula. The data for solid-state batteries and lithium manganese iron phosphate are current research and development and forecast values, and may change after mass production.)

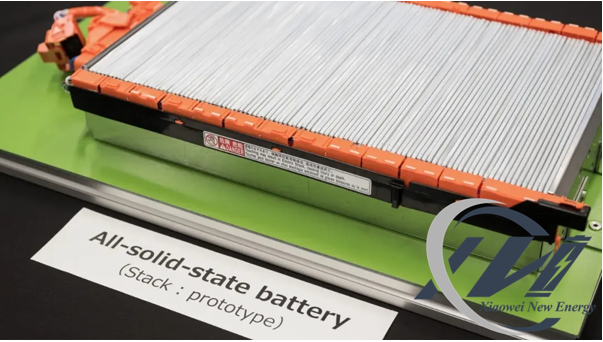

The next generation of “trump card”: the infinite possibilities of solid-state battery positive electrodes

In order to break through the bottleneck of existing liquid batteries in energy density and safety, solid-state batteries are considered to be an important development direction in the future. The biggest feature of solid-state batteries is that they replace traditional liquid electrolytes with solid electrolytes, which brings higher safety and fundamentally eliminates the risk of combustion and explosion caused by electrolyte leakage or high temperature in liquid batteries. In terms of the selection of positive electrode materials, solid-state batteries also show more possibilities and are expected to significantly increase energy density.

Sulfide solid-state battery:

This type of solid electrolyte usually has high ionic conductivity, even comparable to liquid electrolyte, and is therefore considered a potential direction for achieving high energy density. For example, some studies have shown that the theoretical energy density of sulfide solid electrolytes combined with high-nickel ternary positive electrodes and lithium metal negative electrodes is expected to exceed 400Wh/kg, or even higher. However, sulfide materials are sensitive to humidity, and the interface stability still needs to be further improved.

Oxide solid-state batteries:

Oxide solid-state electrolytes have good thermal and chemical stability, and show good compatibility with a variety of cathode materials including high-nickel ternary materials. Although their ionic conductivity is generally lower than that of sulfides, it is also constantly improving. The energy density of some oxide solid-state batteries has shown potential of more than 300Wh/kg. In addition, oxide solid-state electrolytes may also have advantages in terms of cost and ease of large-scale production.

Although solid-state batteries are still in the early stages of industrialization, their great potential in energy density is exciting. For example, solid-state battery prototypes demonstrated by some leading companies have also achieved an energy density of 350Wh/kg or even higher. By combining high-nickel ternary or even lithium metal negative electrodes, solid-state batteries can theoretically achieve energy densities far exceeding existing liquid batteries, and are expected to increase the range of electric vehicles to a whole new level.

The ultimate battle between performance and cost

We can see that different positive electrode materials have their own advantages and disadvantages, and the choice between them is often a trade-off between performance (energy density, safety, cycle life) and cost.

- In pursuit of long battery life and high performance, it is often necessary to choose ternary materials with higher energy density, but this usually means higher costs and higher safety risks.

- Focusing on safety and cost, lithium iron phosphate is a more reliable choice, but it is relatively limited in energy density.

On the one hand, future technological development lies in continuously improving the performance of existing materials, such as improving the energy density and low-temperature performance of LFP through doping, coating and other means, and improving the safety of ternary materials. On the other hand, it also lies in accelerating the research and development and mass production of next-generation cathode materials and solid-state batteries, striving to find the best balance between safety, high energy density and low cost.

The selection of cathode materials for power batteries is like deploying troops, which needs to be determined according to the needs of different specific scenarios. From economical and practical lithium iron phosphate, to ternary materials that pursue extreme energy, to promising solid-state batteries in the future, this is a never-ending game of performance and cost. The technical route that ultimately wins will profoundly affect the future pattern of electric travel.