For construction companies operating heavy machinery, fuel costs represent one of the largest line items in operational budgets. When equipment sits idle or consumes excessive diesel during demanding tasks, profit margins shrink rapidly. The Cummins QSK23 engine stands as a formidable powerplant designed specifically for the rigors of construction, mining, and other heavy-duty applications, delivering robust performance while incorporating advanced fuel-saving technologies. However, even the most sophisticated engine faces a persistent challenge: high fuel consumption can cripple project economics and strain operational budgets. This article provides construction fleet managers and equipment operators with concrete, actionable strategies to extract maximum fuel efficiency from the QSK23 engine. By implementing smart operational techniques, maintaining disciplined service schedules, and leveraging modern monitoring technology, companies can significantly reduce fuel costs while ensuring their equipment delivers consistent, reliable performance. These approaches directly address the dual imperatives of sourcing cost-effective fuel solutions and maintaining high-performance equipment that minimizes costly downtime on active job sites.

Understanding the Cummins QSK23 Engine and Its Efficiency Potential

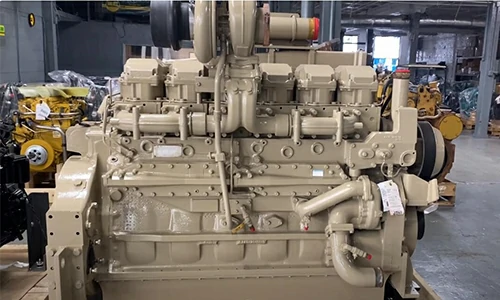

The Cummins QSK23 is a formidable 23-liter inline-six diesel engine engineered to deliver exceptional power in the harshest operating environments. With output ranging from 600 to over 1,000 horsepower depending on configuration, this powerplant drives excavators, haul trucks, drilling rigs, and other mission-critical construction equipment. Cummins designed the QSK23 around durability and efficiency, incorporating a high-pressure common rail fuel injection system that precisely meters fuel delivery across all operating conditions. This advanced injection technology, combined with optimized combustion chamber geometry and electronic engine management, allows the QSK23 to extract maximum energy from every drop of diesel while meeting stringent emissions standards. The engine’s sophisticated turbocharging system further enhances efficiency by recovering exhaust energy to boost intake air density, improving combustion completeness. Despite these factory-engineered advantages, real-world fuel economy varies dramatically based on how operators handle the equipment and how maintenance teams care for critical systems. An improperly maintained QSK23 or one operated outside its optimal performance envelope can consume 15-25% more fuel than necessary, transforming an efficient design into a budget liability. Understanding this baseline efficiency potential establishes realistic expectations and highlights why operational discipline matters as much as engineering excellence.

Operational Best Practices for Optimal Fuel Economy

Mastering the Power Band and Avoiding Over-Revving

The QSK23 delivers peak fuel efficiency when operators keep engine speed between 1,400 and 1,800 RPM during sustained work cycles. Running consistently above 2,000 RPM burns significantly more fuel without proportional productivity gains, as the engine moves beyond its torque sweet spot. Construction operators should monitor tachometers closely and throttle back when full power isn’t required for the immediate task. Equally wasteful is excessive idling, a pervasive habit on job sites where equipment sits running during breaks, meetings, or material delays. A QSK23 idling for one hour consumes approximately one gallon of diesel while producing zero productive work. Implementing a five-minute idling policy—shutting down equipment if delays exceed this threshold—can reduce daily fuel consumption by 10-15% across a fleet. Modern QSK23 engines restart quickly and reliably, eliminating the outdated concern about excessive start cycles damaging components. Training operators to recognize when loads genuinely require high RPM versus when lower speeds suffice creates immediate fuel savings without compromising project timelines.

Progressive Shifting and Load Management

Aggressive throttle application and abrupt gear changes force the QSK23 to operate inefficiently, dumping excess fuel to meet sudden power demands. Operators should practice progressive acceleration, allowing the turbocharger to spool smoothly and the fuel system to optimize injection timing. When operating equipment with manual or semi-automatic transmissions, shifting at the lower end of each gear’s RPM range keeps the engine in its efficient zone. Equally important is matching equipment capability to task requirements—using a 1,000-horsepower configuration for jobs that need only 700 horsepower wastes fuel through unnecessary engine capacity. Fleet managers should analyze typical job profiles and deploy appropriately rated equipment, reserving maximum-power units for genuinely demanding applications. Operators must also avoid lugging the engine by selecting gears too high for the load, which forces inefficient combustion and increases fuel consumption. Understanding the specific work cycle—whether excavating, hauling, or drilling—allows operators to anticipate power needs and maintain steady engine loads rather than cycling between extremes, a practice that consistently delivers 8-12% fuel savings in documented field studies.

Strategic Maintenance: The Foundation of Fuel Efficiency

Critical System Checks and Replacements

A clogged air filter ranks among the most common yet preventable causes of excessive fuel consumption in QSK23 engines. Restricted airflow forces the engine to compensate by enriching the fuel mixture, directly increasing diesel burn rates by 5-10%. Construction environments generate tremendous dust and particulate matter, requiring air filter inspections every 250 operating hours rather than relying solely on manufacturer intervals. Visual checks should confirm filter element integrity, and replacement becomes mandatory when restriction indicators activate or when visual contamination appears moderate. Fuel filters demand equal vigilance, as contaminated diesel degrades injector performance and disrupts the precise spray patterns essential for complete combustion. Changing fuel filters at 500-hour intervals using genuine Cummins parts prevents injector fouling that can increase fuel consumption by 8-15% while risking costly component damage. The turbocharger system requires regular inspection for shaft play, oil leaks, and exhaust restrictions, as even minor turbo inefficiency reduces boost pressure and forces the engine to work harder for equivalent output. Cleaning or replacing exhaust components when backpressure exceeds specifications restores proper turbo function and immediately improves fuel economy.

Fluid Management and Engine Tuning

Engine oil selection directly impacts internal friction and fuel efficiency in the QSK23. Using Cummins-recommended 15W-40 or synthetic alternatives formulated for heavy-duty diesel service reduces parasitic drag on moving components, typically improving fuel economy by 2-3% compared to incorrect viscosity grades. Oil change intervals must follow severe-service schedules in dusty construction environments—typically every 500 hours—as degraded lubricant increases friction and allows combustion byproducts to accelerate wear. Beyond fluid basics, the QSK23’s Electronic Control Module requires periodic calibration updates that Cummins releases to optimize fuel mapping, injection timing, and emissions performance. Authorized service centers can flash updated software and perform diagnostic health checks that identify developing issues before they compromise efficiency. Professional ECM tuning ensures the engine operates within its designed parameters, correcting drift that naturally occurs over thousands of operating hours. This electronic maintenance, often overlooked in favor of mechanical tasks, can restore 3-5% fuel efficiency lost to gradual calibration degradation while maintaining emissions compliance and warranty coverage.

Leveraging Technology and Telematics for Data-Driven Savings

Interpreting Engine Data and Alerts

Modern QSK23 engines come equipped with sophisticated onboard diagnostics that continuously monitor dozens of performance parameters, transforming raw sensor data into actionable efficiency insights. The Electronic Control Module logs fuel consumption rates, engine load percentages, temperature variations, and operational time across different RPM ranges, creating a detailed portrait of how each machine actually works in the field. Fleet managers should connect compatible telematics devices that transmit this data wirelessly to centralized dashboards, allowing real-time visibility into which operators consistently achieve superior fuel economy and which machines exhibit concerning consumption patterns. When the system flags excessive idling—say, an excavator running four hours daily at zero load—managers can intervene immediately with targeted operator coaching rather than discovering the waste weeks later through fuel invoices. Diagnostic alerts for developing issues like injector misfires, turbocharger inefficiency, or air intake restrictions appear long before operators notice performance degradation, enabling preemptive maintenance that prevents the 10-20% fuel penalties associated with neglected problems. By reviewing weekly fuel consumption reports sorted by machine and operator, construction companies identify specific inefficiencies rather than accepting fleet-wide averages, pinpointing exactly where training or mechanical attention delivers maximum return on investment.

Implementing a Fleet Management Strategy

Aggregated telematics data from multiple QSK23-powered machines enables strategic decisions that compound individual efficiency gains into substantial fleet-wide savings. Construction managers should establish baseline fuel consumption metrics for each equipment type during standard tasks—excavation, material transport, grading—then benchmark individual machines and operators against these norms. Operators consistently performing 15% below baseline warrant recognition and should mentor colleagues, spreading best practices organically through the workforce. Route optimization becomes possible when GPS telematics reveal that certain haul trucks travel unnecessarily long paths between loading and dumping points, burning extra diesel that simple route adjustments eliminate. Predictive maintenance scheduling uses actual operating hours and load data rather than arbitrary calendar intervals, ensuring service happens when genuinely needed while avoiding premature part replacement that wastes resources. Perhaps most valuably, fleet-wide data reveals whether specific job sites or project types consistently generate poor fuel economy, prompting investigation into whether environmental factors, material characteristics, or work sequencing create avoidable inefficiencies. Many construction companies working with diesel engine specialists like GRT have implemented comprehensive telematics strategies and typically achieve 12-18% fuel reductions within the first year, with savings continuing as data-driven decision-making becomes embedded in operational culture and equipment deployment planning.

Achieving Long-Term Fuel Efficiency and Operational Excellence

Maximizing fuel efficiency with the Cummins QSK23 engine rests on three interconnected pillars: disciplined operational practices, strategic preventative maintenance, and intelligent use of monitoring technology. When construction operators master the engine’s power band, eliminate wasteful idling, and apply progressive throttle control, they unlock immediate fuel savings without sacrificing productivity. Pairing these behaviors with rigorous maintenance schedules—timely air and fuel filter replacements, proper fluid management, and regular ECM calibration—ensures the QSK23 continues delivering its engineered efficiency potential across thousands of operating hours. Telematics and fleet data transform these individual practices into systematic improvements, revealing patterns and opportunities invisible to manual observation. The financial benefits extend far beyond reduced diesel purchases. A well-operated, properly maintained QSK23 experiences fewer breakdowns, requires less emergency repair, and maintains consistent performance that keeps construction projects on schedule. Downtime costs construction companies exponentially more than fuel expenses, making efficiency investments doubly valuable. As equipment acquisition costs rise and project margins tighten, companies that commit to these fuel-saving disciplines position themselves for sustained competitive advantage, turning their QSK23-powered fleets into strategic assets that deliver reliable performance and predictable operating economics year after year.