When launching a new electronics product, success depends heavily on the quality and reliability of your manufacturing partners. One of the most important steps is selecting the right PCBA service and supplier. Whether you’re working on smart home devices, industrial controllers, or automotive electronics, your choice of PCBA supplier can make or break your product.

This article will help you understand what to look for in a PCBA service and how to choose a dependable PCBA supplier that fits your specific needs.

Understanding PCBA Service

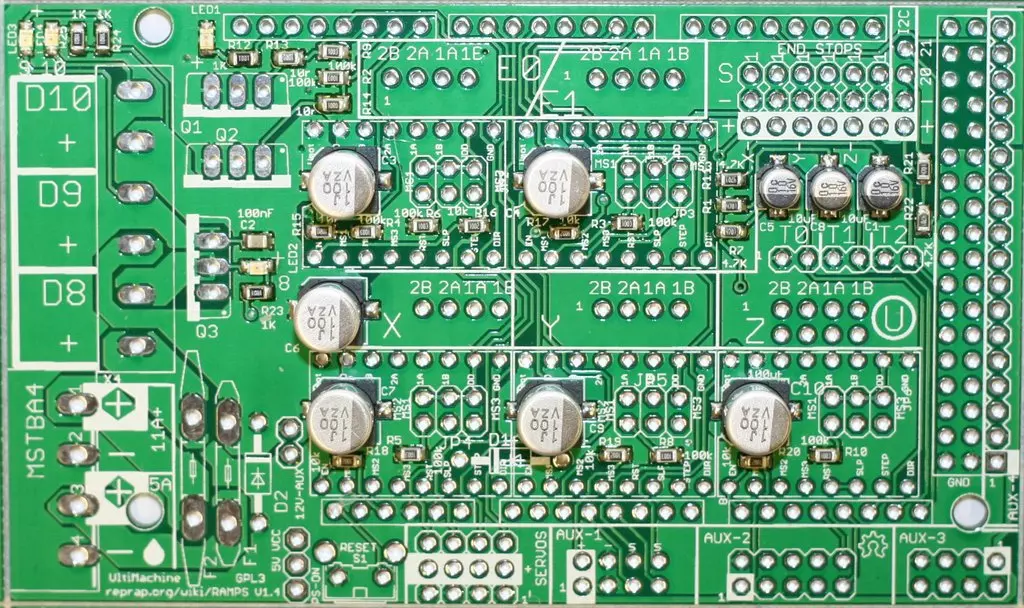

PCBA stands for Printed Circuit Board Assembly. It is the process of mounting electronic components onto a PCB to create a complete, working circuit. A full PCBA service typically includes:

- PCB manufacturing or sourcing

- Component procurement

- Surface mount and through-hole assembly

- Reflow or wave soldering

- Quality inspections like AOI and X-ray

- Electrical testing and functional verification

A reliable PCBA service ensures that every board leaving the factory meets your technical and quality standards.

What Makes a Good PCBA Supplier?

A good PCBA supplier goes beyond just assembly work. They become an extension of your engineering and production team. Here are the key traits of a strong PCBA supplier:

- Technical expertise in both SMT and THT assembly

- Modern production lines with automated equipment

- Cleanroom or ESD-safe environments

- In-house engineering support to review your BOM and Gerber files

- Quality certifications (such as ISO9001, IATF16949, ISO13485)

- Experience in your target industry (medical, telecom, IoT, etc.)

- Flexible order quantities for both prototypes and mass production

Before making a decision, ask about their process controls, customer service, and typical turnaround times.

Why Working with the Right PCBA Supplier Matters

Choosing the wrong PCBA supplier can lead to:

- Delays in product launch

- Defective or unreliable products

- Poor communication during development

- Supply chain issues with components

- Unexpected costs from rework or quality problems

In contrast, a trusted PCBA service provider helps you:

- Reduce time to market

- Improve yield and product consistency

- Scale quickly as demand grows

- Save money in the long run with fewer mistakes

PCBasic: A Reliable PCBA Partner for Global Clients

PCBasic is a one-stop PCBA service provider based in Shenzhen, China. Since 2011, we’ve delivered high-quality PCB assembly solutions for clients in Europe, Asia, and North America.

Our factory is equipped with advanced SMT lines, reflow ovens, AOI/X-ray inspection systems, and functional test stations. Whether you’re building medical devices, industrial systems, or consumer electronics, we support you with:

- Fast turnaround on small and medium batch orders

- Strong quality control processes

- Engineering support for design optimization

- Global logistics and secure packaging

- Competitive pricing with no compromise on performance

PCBasic is more than just a PCBA supplier — we’re your long-term partner in innovation.

Final Tips for Selecting Your PCBA Supplier

To choose the best PCBA supplier for your needs, consider the following:

- Review their case studies and past projects

- Visit the factory or request a virtual tour

- Check for transparency in communication and quoting

- Evaluate their responsiveness to your technical questions

- Start with a prototype batch to test quality and service

By investing time in finding the right PCBA service provider, you’ll gain a valuable partner who helps bring your ideas to life with speed and precision.

Need help with your next project? Contact PCBasic today and let our PCBA service team deliver reliable solutions for your electronics success.