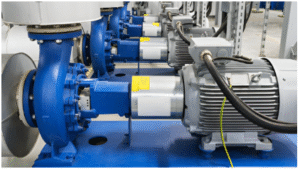

For things never stop moving in big factories. Every minute of every day, machines pump, push and carry liquids. These liquids can be hot, thick or even dangerous. To keep everything working, pumps must be strong and steady. GTC Pumps builds pumps that can handle these very hard jobs. Their machines are trusted in places where a normal industrial pump would quickly break down. This article explains how GTC Pumps makes sure its machines stay strong for years, even in the toughest industrial environments. It covers their design, materials, safety, testing, and the real reasons they last longer.

- Working in Harsh Environments Is Not Easy

- Leak-Free Design for Safety and Durability

- Handling Tough and Dangerous Liquids

- Continuous Operation Around the Clock

- Quality Control and Strict Testing

- Energy Efficiency and Smart Performance

- Reduced Maintenance and Lower Costs

- Trusted Across Many Industries

- Standing Strong Against Time

- Conclusion

Working in Harsh Environments Is Not Easy

Factories, chemical plants, and oil sites are not gentle places. Machines there deal with heat, pressure, and strong liquids. Sometimes, these liquids can burn or eat away metal. Other times, dust, dirt, or sand can block pipes and wear down parts. In such places, even a small problem can stop a full line of production. When that happens, time and money are lost. That’s why pumps must not only work, but they must keep working for years. GTC Pumps understands these hard conditions very well. Every pump they build is designed to face this kind of stress and still run smoothly.

Leak-Free Design for Safety and Durability

Leaks are a big problem in any industrial setting. When a pump leaks, a safety risk, an environmental impact and a waste of materials may be the result. GTC Pumps works hard to prevent this from occurring. Their pumps are equipped with strong seals that ensure there are no leaks that can occur to them at all, despite the high pressure created. The body of each pump is built very tightly so that it is not possible for liquid to escape from it. This makes the pumps safer to use and helps to make them last longer. The leaking fluids can cause damage to the internal parts over time. By keeping it all sealed and secure, GTC Pumps helps factories to be safe and clean, not to mention helping to protect the environment.

Handling Tough and Dangerous Liquids

Not all liquids are easy to pump. Some are sugary thick like syrup, some are hot like steam, and some are full of small particles, causing scrapes on metal. GTC Pumps makes its machines capable of handling all types of tough liquids. For example, in chemical industries, pumps may need to transport acids or bases that may destroy normal metal. In oil and gas plants, the fluids can be filled with sand or mud. GTC Pumps constructs models that will work with these materials without getting damaged quickly. This ability to handle the difficult liquids is one of the biggest reasons why GTC Pumps are trusted in ‘rough’ industrial areas.

Continuous Operation Around the Clock

Many factories don’t stop running. Some work 24 hours a day, 7 days a week. For that, pumps must run continuously without losing power. GTC Pumps are made exactly for that. They are tested to work for long hours under heavy loads. The motors, bearings, and other parts can handle constant stress. This makes them ideal for plants that need non-stop performance. Because of this strong design, factories don’t have to replace their pumps often. The pumps keep running, and workers can focus on production instead of repairs.

Quality Control and Strict Testing

Before a pump is ever delivered to a factory, it undergoes testing. GTC Pumps puts each pump through a series of pressure, temperature, and leakage tests following API 610 and ISO 5199 specifications on safety and durability. This assures the constant high quality before shipment. This is careful testing to avoid problems in the future; it is a saving for the factories in the long run.

Energy Efficiency and Smart Performance

A reliable pump doesn’t just last long, but it should also save energy. GTC Pumps designs machines that use power wisely. Their motors are efficient, meaning that they are able to move more fluidly while using less energy. This also means less expenditure on spare parts and less labor. Even if the initial cost of a GTC Pump is higher, the cost over time is extremely low. That’s because the pumps last longer in service and rarely need to be replaced. In the long term, one good pump is always cheaper than one that fails frequently.

Reduced Maintenance and Lower Costs

Strong design and materials also mean less maintenance. GTC Pumps require fewer check-ups compared to ordinary pumps. Since parts last longer and resist wear, factories don’t have to stop production often. This also means less spending on spare parts and labor. Even though the initial cost of a GTC Pump might be higher, the total cost over time is much lower. That’s because the pumps are in service longer and do not often require replacement. In the long run, it is always cheaper to have a good pump that doesn’t break on you too often.

Trusted Across Many Industries

GTC Pumps are used in many types of industries. Chemical factories, power plants, refineries, food processors, and water treatment sites all rely on them, sharing one key need: reliable equipment. GTC Pumps has proven reliable in all these areas. Whether it’s moving clean water or thick oil, the pumps continue to work with the same stability and performance. That wide range of use shows that the design truly works, even under very different and tough conditions.

Standing Strong Against Time

Machines are old, but not all are aged at the same rate. GTC Pumps are constructed to retard that aging process. Their solid build and strong parts, and careful design ensure against rust, wear and fatigue. After years of operation, most pumps lose pressure or begin hemorrhaging. GTC Pumps, on the other hand, keep performing well because they are built to handle constant stress. They resist vibration and other small issues that can wear out machines over time. Because of this, many factories rely on GTC Pumps for long-term service without constant worry.

Conclusion

In the world of heavy industry, reliability is everything. Machines that fail can cause big losses and even danger. GTC Pumps knows this better than most. Their pumps are built from strong materials, tested carefully, and designed to handle extreme conditions. From chemical plants to oil refineries, these pumps prove that durability and smart design can work together. They resist leaks, save energy, and last many years without giving up. When a company requires a pump that needs to continue running in a state of heat, pressure, or harsh chemicals, that is the peace of mind that GTC Pumps brings. Their machines are not simply made to work; they are made to last.

![Exploring the Life and Legacy of len pullen: A Trailblazer in [Field/Industry]](https://reelsmedia.co.uk/wp-content/uploads/2025/02/len-pullen-2-330x220.jpg)