The process of 3D printing, also known as additive manufacturing, exists. The technology produces objects through consecutive layer addition. A digital file functions as the decision-making authority to define object shape and dimensions. The system produces products by creating individual layers before proceeding to the next ones. The procedure has many applications in present-day society.

3D printing finds applications in the medical field and serves several art and fashion needs and supports various industries. The production facility creates automobile components along with manufacturing building materials through its operations. 3D printing technology, among others, comes with a combination of beneficial and unfavorable elements.

The following section evaluates both the potential benefits and the drawbacks that 3D printing technology delivers.

What Is 3D Printing?

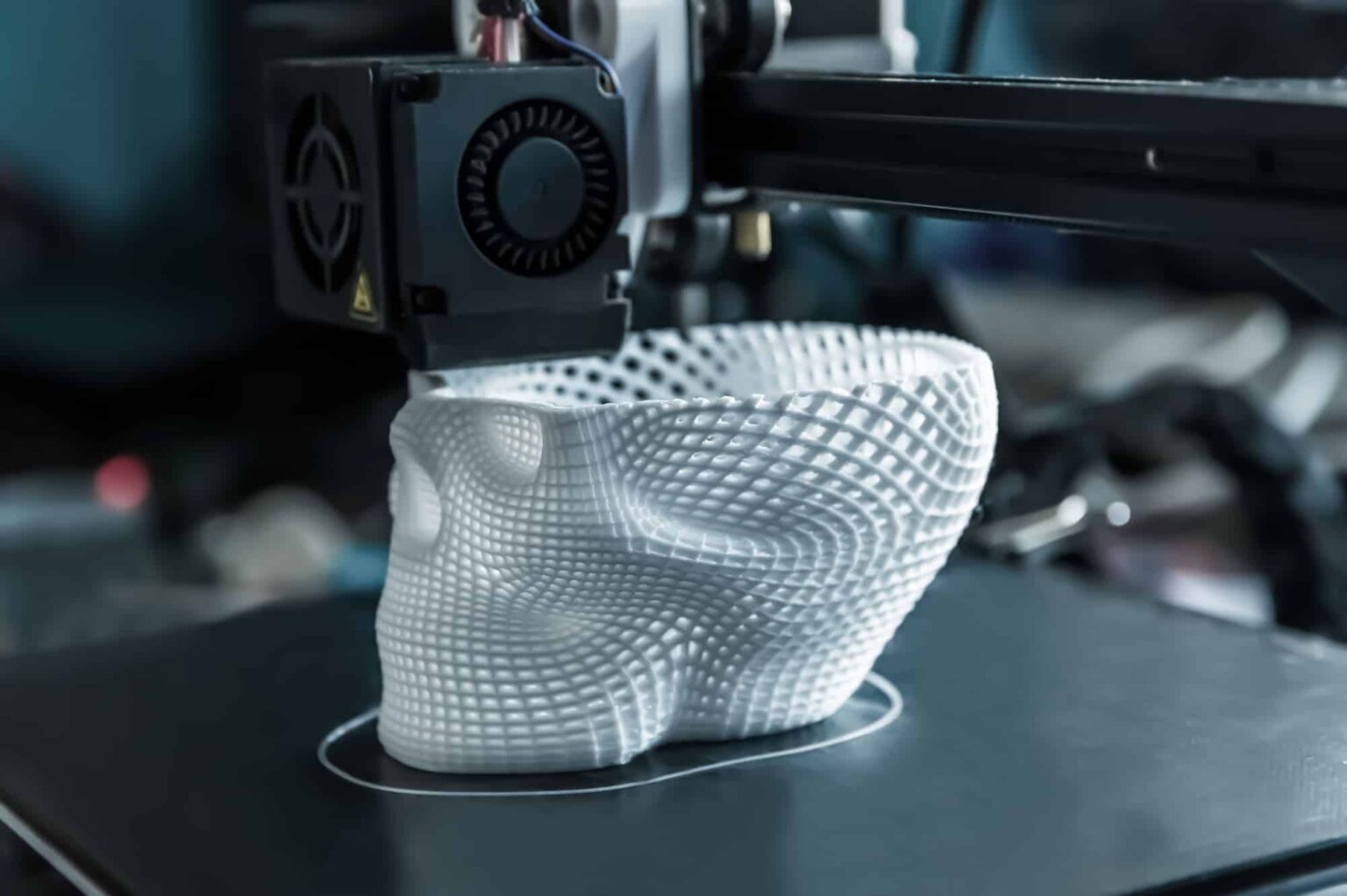

The contemporary technology known as 3D printing enables production of fabricated objects through layer creation method. The printing equipment uses material substances including plastic together with resin and metal to create its output. The printer operates through computer files which direct it to construct objects by adding layers one by one.

3D printing functions in aa uniqueway in comparison to conventional manufacturing approaches. The technology does not subtract materials to shape objects but builds everything originally.

Advantages of 3D Printing

3D printing has many benefits. The method enables fast production alongside creativity, and in some instances, it decreases expenses. Read more.

1. Faster Prototyping

Quick sample creation is possible for designers using this method. The testing process becomes faster through this method.

Molds, along with heavy machine,s are unnecessary for their operation. One computer file enables the production of multiple sample items.

2. Customization

Different production methods result in unique versions for every object. The personal and medical product category benefits from 3D printing services.

Doctors employ their printing machines to create individualized braces, along with hearing aids and replacement human body structures.

3. Less Waste

The production technique eliminates unnecessary materials through traditional methods. That creates a lot of waste.

The utilization in 3D printing restricts the addition of superfluous elements. Because of this approach, there is less unused material.

4. Cost-Effective for Small Batches

Using 3D printers becomes cost-effective during the production of limited numbers of items. To produce your items you do not need any special equipment or tools.

Small businesses, together with inventors, reduce their expenses due to 3D printing.

5. Complex Designs

The models produced by 3D printers cannot be easily replicated through manual techniques.

A 3D printer enables users to create both movable and empty aspects during single-step production.

6. Easy Changes

Modify your file to solve any mistakes found within it. You can continue working after any adjustments because restarting from beginning is unnecessary.

Such workflow methods shorten both working hours and labor intensity.

Benefits of 3D Printing

- Fast production for prototypes

- Custom parts and products

- Less material waste

- Lower setup cost

- Complex design possible

- Easy file updates

- Good for home use

Disadvantages of 3D Printing

The multiple benefits of 3D printing do not erase its existing disadvantages. These can limit its use.

1. Slow for Mass Production

It is fast for one item. But for many, it is slow.

Industrial factories continue to depend upon traditional manufacturing approaches to achieve speedier production output.

2. Limited Materials

3D printers use only certain materials. The technology prevents numerous users from creating metal or tough plastic structures.

The printing process fails to deliver either heat or pressurization, which certain items require.

3. High Equipment Cost

Good 3D printers can be expensive. The machinery together with its accompanying materials along with programming software both carry high costs.

Small shops, together with schools, struggle to provide this equipment.

4. Weak Parts

The strength of parts produced through printing methods remains inconsistent. Layer-by-layer parts may break more easily.

Under both heat exposure and pressure, these items lack resistance to failure.

5. Copyright Problems

A copied design and its corresponding print job could be accessible to everyone. This can cause legal issues.

The prevention of individuals from stealing intellectual works proves difficult.

6. Skills Needed

Learning the operation of 3D printers requires specific training. Most users find design software demanding for learning purposes.

Problems associated with fixing printer malfunctions often present significant difficulty.

Environmental Impact

The planet benefits from 3D printing through some specific advantages. It uses less material. 3D printing allows production near where items will be used to reduce shipping needs.

The system still requires plastic components together with electrical power consumption. The absence of plastic recycling leads to its production becoming waste. The heating process releases toxic gases from several materials.

Safe materials need to be utilized while we strategize effective recycling practices. Sustainable operation in nature becomes easier through its implementation.

Where Is 3D Printing Used?

Many fields depend on 3D printing technologies for their operations today. Some examples include:

- Medical field (bones, implants, and tools)

- Automotive industry (car parts and tools)

- Fashion and jewelry (custom designs)

- Education (student projects and models)

- Home use (toys and tools)

- The technology has gained interest from an increasing number of business sectors.

Conclusion

Modern technology is distinguished by its potent and intelligent characteristics that make 3D printing possible. This technology streamlines work operations because it operates at a superior speed. People have the capability to produce practical articles directly from their domestic locations and business offices. The technology enables monetary savings during execution of smaller-scale projects.

But 3D printing has limits. The technology proves inappropriate for complete job applications. Special materials together with tools and knowledge are required for operation. Traditional production techniques will remain predominant even shortly.

Still, it is a growing field. With time, it will improve. The correct application of this technology possesses the ability to transform production methods permanently.