Shipping delicate products through tropical regions, coastal areas, and other high-humidity environments can be quite a challenge for businesses. Issues like moisture damage, product deterioration, and packaging failures can result in significant losses and leave customers unhappy. That’s where molded pulp packaging comes in—it’s a fantastic solution for these tough conditions, providing a level of protection that traditional packaging just can’t compete with.

Understanding the High-Humidity Shipping Challenge

The high humidity shipping routes always include tropical areas in South East Asia, transportation routes along the coastline, as well as ship routes where the relative humidity is likely to be above 80%. This is where packaging fails in a worse way than in any other area in the world. Cardboard packaging is prone to absorbing humidity and even assists in mold development.

The impact does not stop there, though. Electronics, medications, and other commodities may be permanently damaged if their packaging is not functioning properly in humid environments. It is more than a mere transport-related choice, then, that is necessary in making packaging decisions; it is an essential business imperative, in fact.

What Makes Molded Pulp Packaging Different

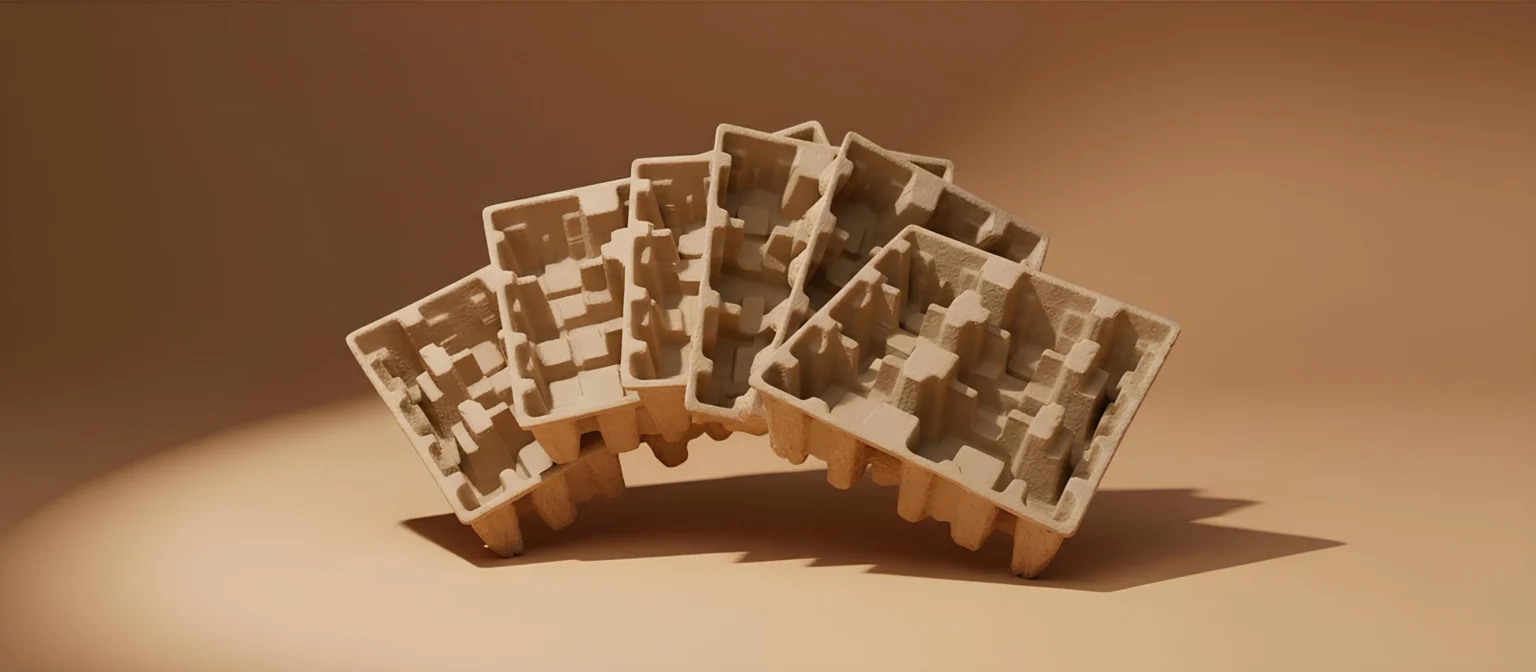

Molded pulp packaging is crafted from recycled paper fibers that are shaped into specific designs using molds. Unlike standard flat paperboard, this three-dimensional forming technique gives it unique characteristics that shine in tough conditions. The process involves mixing a pulp slurry, pressing it into shape, and then drying it to produce sturdy, custom-fitted packaging solutions. This approach results in packaging that boasts better structural qualities compared to traditional options.

Superior Moisture Resistance Through Design

One of its greatest benefits is the controlled moisture management of molded pulp. Its fiber structure enables it to absorb and then dry slowly without compromising its dimensions. For instance, common cardboard will disintegrate if it comes into contact with water, but molded pulp remains intact regardless of humidity levels.

Moreover, it prevents condensation buildup within the package, especially for moisture-sensitive materials. One other benefit is the ability for air to flow because molded pulp is a breathable product that ensures air is circulating while providing a protective buffer that shields the product during shipping by creating a balanced micro-environment.

Structural Integrity in Extreme Conditions

The three-dimensional molding process gives packaging a solid structural strength that’s hard to beat. Unlike cardboard boxes, which depend mainly on surface tension, molded pulp spreads stress evenly throughout its entire shape. This design advantage means the packaging can handle the weight of stacked shipments without buckling or warping, even when humidity takes a toll on other materials.

Tests have shown that wet press molded pulp packaging can keep up to 90% of its compressive strength, even in really humid conditions. In contrast, traditional corrugated cardboard can lose more than half of its strength when faced with similar moisture levels. This reliability leads to less product damage and fewer insurance claims.

Temperature Regulation and Condensation Prevention

Temperature variations on high-humidity shipping routes frequently result in condensation inside packages. The cellular structure of molded pulp offers inherent insulating qualities that lessen condensation and moderate temperature fluctuations.

Throughout the shipping process, the material keeps products in a more stable environment by acting as a buffer against changes in the outside temperature. This thermal control is especially useful for delicate products that can be harmed by moisture buildup, such as electronics, cosmetics, and some food items.

Sustainability Meets Performance

Apart from its functional superiority, molded pulp packaging also fits the escalating sustainability criteria of worldwide shipping. This material is fully biodegradable and made from 100% recycled materials.

Within shipping routes where humidity is a factor, some of these routes also fall in environmentally regulated areas. Molded pulp packaging materials enable businesses to comply with environmental requirements effectively, even when improving product packaging quality compared to other packaging alternatives like cardboard boxes that result in environmental degradation when properly disposed of at the end of their useful lives.

Cost-Effectiveness Over the Complete Shipping Cycle

While molded pulp packaging might come with a slightly higher initial price tag than basic cardboard, the overall cost of ownership tells a different tale. With lower damage rates, you’ll see fewer returns, replacements, and customer service headaches. Plus, the durability of this material means you won’t need to worry about adding extra moisture barriers or desiccant packets that many shippers use with traditional packaging.

Using top-notch protective packaging can even lead to lower insurance premiums, and the lighter weight compared to plastic options can help cut down on shipping costs. When you look at the entire supply chain, molded pulp often turns out to be more cost-effective than those cheaper alternatives that struggle in humid conditions.

Customization for Specific Product Needs

For almost any product shape or size, molded pulp can be precisely engineered to provide protection. In high-humidity settings, where any gap or void in the packaging could trap moisture and cause damage, this precise fit is especially crucial.

Fiber density, thickness, and composition can all be changed by manufacturers to maximize performance for particular humidity levels and product specifications. Molded pulp can be used for anything from heavy machinery parts to delicate glassware because of its customizable nature.

Real-World Performance in Critical Shipping Lanes

Carriers operating on Asia-Pacific trade routes, across the Atlantic, and on other humid routes have found dramatic improvements with molded pulp packaging solutions. Damage claims have decreased by 40% to 60% in these instances. Customer satisfaction and reverse logistics expenses decreased along with them.

The packaging works exceptionally well in intermodal transportation applications where products go through various transitions of climatic conditions, starting from fully air-conditioned godowns to wet docks to fully air-conditioned containers and vice versa.

Making the Transition to Molded Pulp Packaging

Making the switch to molded pulp packaging means teaming up with seasoned manufacturers who really get the ins and outs of material science and the challenges of shipping routes. It’s a smart move for companies to start with pilot programs on their most at-risk routes, keeping an eye on damage rates and costs before rolling it out fully.

This transition often uncovers extra perks beyond just resisting humidity, like boosting brand perception since customers really appreciate sustainable packaging options.

Conclusion

Molded pulp packaging offers a combination of cost-effectiveness, sustainability, and protection for companies shipping via high-humidity routes. It is the best option for difficult shipping conditions due to its special capacity to control moisture while preserving structural integrity. Molded pulp packaging provides the dependability and performance that contemporary supply chains require as global trade continues to grow through tropical and coastal regions. In an increasingly competitive market, investing in this cutting-edge packaging solution safeguards not only products but also brand reputation and bottom-line profitability.