The cost of concrete lifting often surprises people, not because it’s high, but because of how effectively it resolves issues that seemed far more complex. Uneven slabs, cracked paths, and shifting driveways aren’t just cosmetic problems. They can damage surrounding structures, interfere with drainage, and create serious trip hazards. Whether you work in construction or manage property assets, it’s an issue you’re likely to face eventually.

How Concrete Lifting Works

Whether it’s a sagging driveway, a tilted kerb, or a warehouse slab that’s no longer level, concrete lifting works by raising the affected area back to its original position. Instead of demolishing and re-pouring the entire slab, the process targets the root cause underneath, notes EquityTeam Management company.

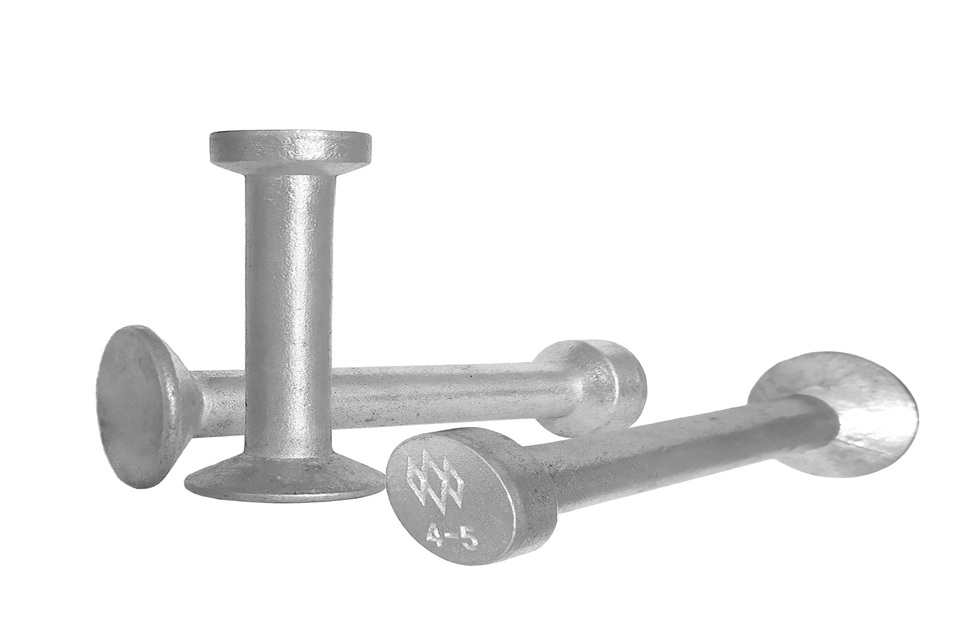

Foot anchors, lifting sockets, and clutches are inserted into or affixed to the concrete. These components are then used to lift the structure safely and evenly using the appropriate equipment. In civil and commercial settings—especially where precast panels are involved—precision is essential. Factors like anchor position, lift angle, and load-bearing capacity must be calculated beforehand to avoid cracking, imbalance, or failure during the lift.

Why Slabs Start to Move

A number of site-specific factors can cause slab movement: poor subgrade compaction, moisture shifts, expanding clay soils, or invasive tree roots. In some locations, the ground expands and contracts significantly based on rainfall or seasonal changes, subtly shifting the slab over time. Freeze-thaw cycles can also contribute to this issue in colder regions.

Once a shift begins, repeated load stress—such as vehicles driving over the area—can accelerate the damage. You might notice misaligned joins, water pooling where it used to drain clearly, or machinery starting to rattle more than usual. These early signs suggest it’s time to consider concrete lifting before more extensive repairs are needed.

When It’s More Than Just a Minor Issue

Sometimes the signs are obvious—a visible dip or crack. Other times, they’re subtle: a door that won’t close properly, a floor that feels uneven underfoot, or a panel that no longer sits flush.

Ignoring these early symptoms can lead to much bigger problems. Water may start to flow incorrectly across a site, or small cracks may grow into structural faults. What could have been resolved with a simple lift may eventually require excavation, foundation repair, or lengthy site shutdowns. Acting early helps prevent further damage and keeps your project timeline intact.

The Hardware Behind a Stable Lift

Successful lifts depend on matching the right hardware to the task. Anchors, sockets, and clutches must be correctly rated for the slab weight and lift technique. Using undersized or incompatible parts increases the risk of cracking or lift failure.

For example, a 2.5-tonne stair unit requires anchors set at specific depths and spaced according to load distribution. Each lift point must carry its share of the weight to avoid distortion. That’s why hardware decisions should be made early—ideally during the planning and design phase—not during installation.

Planning for Lift Points Early

For any precast element—like a stair, kerb, or retaining wall segment—the placement of anchors, the depth of installation, and the type of clutches used should be determined before casting. These choices directly affect how safely and efficiently the piece can be moved later on.

In civil projects, planning lift points in advance ensures structures can be transported and installed without delays or damage. This foresight helps avoid last-minute design changes, awkward re-positioning, or preventable site damage.

Skill Matters Just as Much as Hardware

Even the best equipment needs to be used correctly. Operators must understand weight distribution, component ratings, and the site’s lifting plan. This applies to large-scale builds with cranes, as well as on smaller sites where precision is critical.

Reviewing anchor placement, checking for wear, and coordinating each lift are key to reducing risks and keeping things running smoothly. Training and experience are just as vital as the tools themselves.

Could Your Site Benefit from Concrete Lifting?

If you’re dealing with sunken slabs, uneven concrete, or misaligned panels, concrete lifting could offer a quicker and less disruptive solution than full replacement. When done properly, it restores function, extends the life of your structures, and reduces future repair needs.

To ensure the best results, consult a supplier experienced with your specific project type. They’ll guide you in selecting the right anchors, sockets, and clutches, ensuring your next lift is safe, efficient, and built to last.