When you’re designing parts for manufacturing, understanding CNC machining tolerances can mean the difference between a perfect fit and a costly rejection. Tolerances define the acceptable range of variation in a part’s dimensions, and choosing the right tolerance level directly impacts both quality and cost.

For manufacturers seeking reliable precision, partnering with experienced CNC machining services ensures your tolerance requirements are met consistently. Whether you’re producing aerospace components or consumer products, understanding tolerance standards helps you make smarter design decisions.

What Are CNC Machining Tolerances?

CNC machining tolerances represent the permissible deviation from a specified dimension. When a drawing specifies a hole diameter of 10.00mm ±0.05mm, the acceptable range is 9.95mm to 10.05mm. Any part falling outside this range fails inspection.

Tolerances exist because perfect manufacturing is impossible. Even the most advanced CNC machines experience tool wear, thermal expansion, and material inconsistencies. The question isn’t whether variation occurs—it’s how much variation you can accept for your application.

Standard Tolerance Levels in CNC Machining

The manufacturing industry recognizes several standard tolerance classes:

Standard Tolerances (±0.1mm or ±0.004″) This represents the default capability for most CNC operations without special processes. Standard tolerances suit the majority of mechanical parts where moderate precision suffices. Features like mounting holes, general brackets, and housings typically specify standard tolerances.

Precision Tolerances (±0.05mm or ±0.002″) Precision-level tolerances require careful machine calibration and qualified operators. Parts with mating surfaces, bearing fits, or components in assemblies with multiple parts often need precision tolerances. Achieving this level increases manufacturing time by 20-30% compared to standard tolerances.

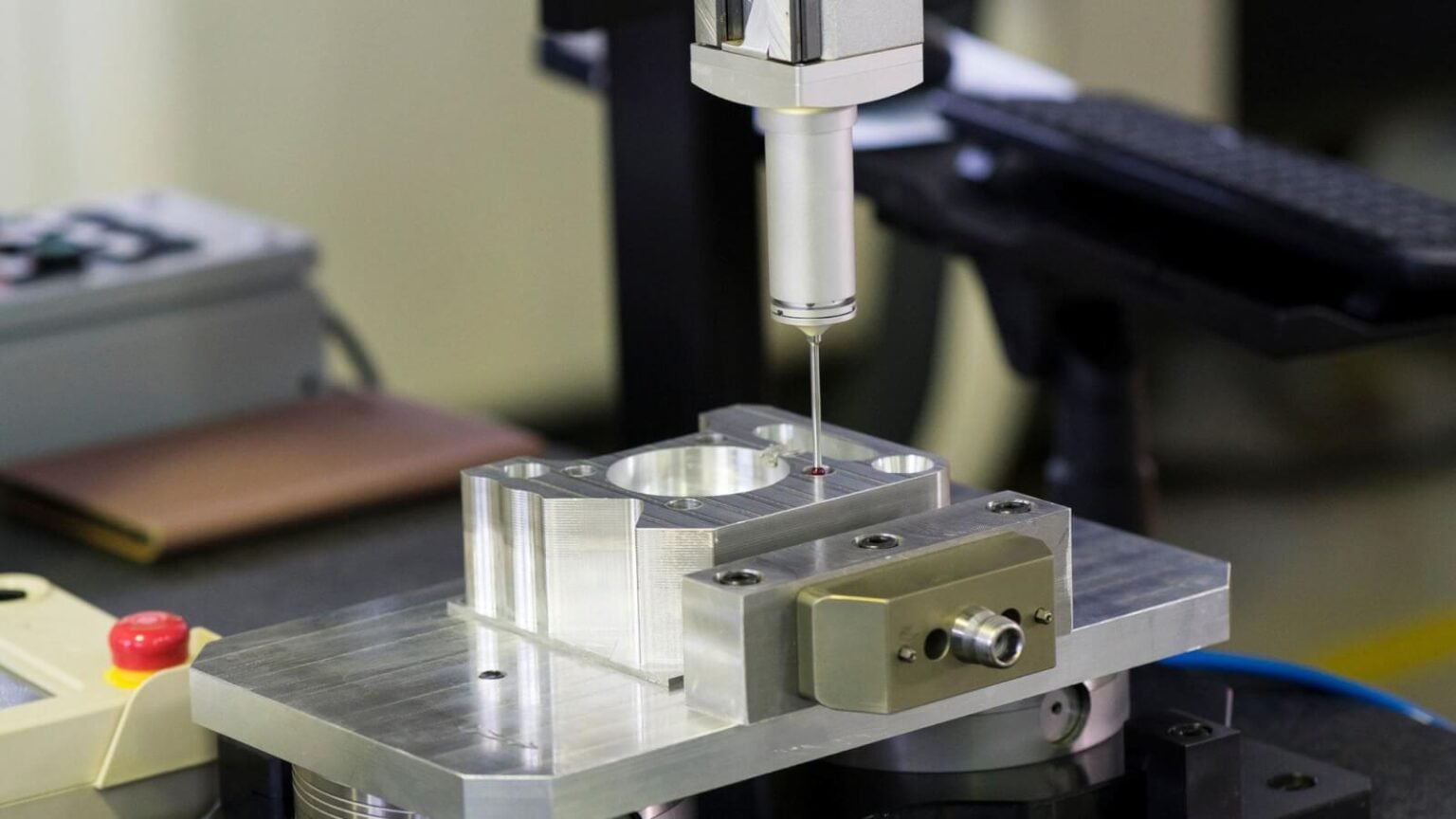

High-Precision Tolerances (±0.01mm or ±0.0004″) High-precision work demands temperature-controlled environments, premium tooling, and frequent measurement. Aerospace components, medical devices, and precision instruments require this tolerance level. A qualified custom parts manufacturer invests in CMM (Coordinate Measuring Machine) equipment and maintains strict process controls to achieve these tolerances consistently.

ltra-Precision Tolerances (±0.005mm or ±0.0002″) Ultra-precision represents the upper limit of conventional CNC machining. At this level, factors like humidity, machine foundation stability, and even time of day affect results. Only specialized applications justify the cost premium—often 3-5x higher than standard tolerance work.

Factors Affecting CNC Tolerance Achievement

Multiple variables influence whether your machined parts meet tolerance requirements:

Machine Capability A machine’s mechanical precision determines its tolerance capability. Older machines with worn ballscrews and slideways struggle with tight tolerances. Modern multi-axis CNC centers with linear encoders and thermal compensation systems maintain precision across temperature fluctuations.

Material Properties Different materials machine to different tolerance levels. Aluminum holds dimensions easily due to its stable properties and low cutting forces. Stainless steel, particularly austenitic grades, work-hardens during machining and can spring back after cutting, making tight tolerances challenging. Plastics exhibit thermal expansion coefficients 5-10x higher than metals, requiring special consideration.

Part Geometry Thin walls, deep pockets, and long unsupported features deflect under cutting forces. A 2mm thick aluminum wall might deflect 0.05mm during machining, then spring back when the cutting tool retracts. Experienced machinists compensate for deflection, but complex geometries inherently limit tolerance achievement.

Tool Wear Cutting tools gradually wear during production. A sharp carbide endmill might hold ±0.01mm, but after machining 100 parts, tool wear introduces dimensional drift. High-volume production requires tool change strategies and in-process measurement to maintain tolerances across entire production runs.

Tolerance Cost Relationship

Tolerance selection dramatically impacts manufacturing costs. As a rule, each 50% reduction in tolerance range doubles machining costs. Here’s why:

Tighter tolerances require slower cutting speeds, smaller depth of cuts, and more frequent tool changes. A feature machined at standard tolerance might take 5 minutes; achieving precision tolerance on the same feature extends time to 8 minutes; high-precision work might require 15 minutes.

Secondary operations multiply costs further. High-precision holes often need grinding or honing after milling. Surface finishes below Ra 0.8μm require additional grinding operations. Each process adds setup time, specialized tooling, and additional inspection steps.

Best Practices for Specifying Tolerances

Smart tolerance specification balances function with manufacturability:

Only Tolerance Critical Features Don’t apply tight tolerances globally. Most parts contain only 2-3 truly critical dimensions. A mounting bracket might have 20 dimensions on the drawing, but perhaps only the mounting hole positions require precision tolerance. Leave non-critical features at standard tolerance or even “remove all sharp edges” specifications.

Consider Assembly Stack-Up When multiple parts assemble together, cumulative tolerances affect final assembly. If three components stack with ±0.1mm tolerance each, the assembly could vary by ±0.3mm. Design with tolerance stack-up in mind, allocating tighter tolerances only where necessary.

Communicate with Your Manufacturer Experienced CNC manufacturers offer Design for Manufacturing (DFM) guidance. Share your functional requirements rather than just dimensional specifications. A knowledgeable manufacturer might suggest alternative approaches that achieve the same function at lower cost.

Tolerance Inspection Methods

Different tolerance levels require different measurement approaches:

Standard tolerances use calipers and micrometers. These hand-held tools provide adequate accuracy for ±0.1mm work. Precision tolerances need height gauges, bore gauges, and pin gauges for reliable verification. High-precision work requires CMM measurement in temperature-controlled rooms.

Statistical Process Control (SPC) helps maintain tolerances in production. By tracking measurements over time, manufacturers identify trends before parts drift out of specification. Leading manufacturers implement SPC as standard practice for tight-tolerance work.

Conclusion

Understanding CNC machining tolerances empowers better design decisions. Specify tolerances based on function, not arbitrary precision. Partner with manufacturers who demonstrate capability through proper equipment, environmental controls, and quality systems. Remember: the tightest tolerance that meets your functional requirements represents the most cost-effective choice.

Whether you need standard production parts or high-precision components, working with experienced CNC professionals ensures your tolerance requirements translate into quality manufactured parts.