The way custom merchandise is produced has changed dramatically in recent years. Creators, online brands, and small businesses no longer rely on long production cycles or large minimum orders to bring their designs to life. Instead, speed, flexibility, and consistency have become the defining factors of successful merchandise production. One printing method that has quietly become a key player in this shift is DTF printing.

DTF, or Direct-to-Film printing, offers a production model that aligns perfectly with today’s fast-moving digital culture. Whether it’s creator merch, limited drops, or small-batch custom apparel, many businesses now rely on professional DTF printing services to move designs from concept to finished product with fewer obstacles than traditional methods.

What Makes DTF Printing Different From Traditional Methods

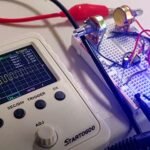

Traditional printing techniques often come with limitations. Screen printing requires extensive setup time and larger production volumes, while other digital methods can struggle with fabric compatibility or long-term durability. DTF printing approaches the process differently.

Designs are printed onto a specialized film and then transferred onto fabric using heat and pressure. This method removes the need for fabric pre-treatment and works effectively across cotton, polyester, blends, and performance fabrics. The result is a clean, flexible print that maintains its appearance through regular wear and washing.

Because the process is digitally driven, production can scale up or down without changing workflows. This makes DTF printing particularly attractive for businesses that operate on demand or experiment with short-run releases.

Why Creators and Brands Are Adopting DTF Transfers

One of the strongest advantages of DTF printing is creative freedom. Complex graphics, detailed illustrations, and full-color designs can be reproduced accurately without additional setup steps. This allows creators to focus on design quality rather than production limitations.

Durability is another key factor. When applied correctly, DTF transfers resist cracking, peeling, and fading. This level of performance is essential for merchandise intended to represent a brand or creator long-term.

DTF printing also supports faster turnaround times. With fewer preparation steps involved, production can begin almost immediately after a design is finalized. This speed is critical for launches tied to trends, events, or limited-time campaigns.

DTF Printing in the Creator Economy

The rise of the creator economy has changed expectations around merchandise. Fans expect unique designs, fast delivery, and professional quality—regardless of order size. DTF printing fits this model by enabling small-batch production without sacrificing consistency.

From apparel to accessories, DTF transfers are being used across a wide range of merchandise categories. This versatility allows creators and brands to expand their product offerings without investing in multiple production systems.

A Flexible Solution for a Fast-Moving Market

As digital platforms continue to shape how products are launched and consumed, production methods must keep pace. DTF printing provides a flexible foundation for modern merchandise workflows by combining speed, adaptability, and reliable output.

Rather than replacing creativity with automation, DTF printing supports it—making it easier for ideas to become tangible products without unnecessary friction.

Looking Ahead

Custom merchandise will continue to evolve alongside online communities, creators, and niche brands. Printing technologies that offer both creative freedom and operational efficiency will remain central to this growth.

DTF printing stands out as a method that meets these demands, offering a balanced approach to modern production. For brands and creators navigating an increasingly competitive digital landscape, flexible printing solutions like DTF provide a clear advantage.