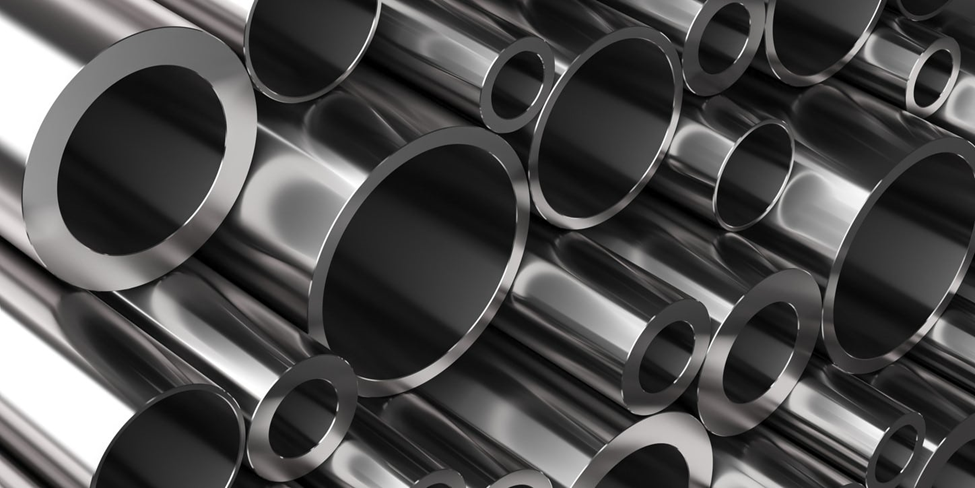

When you buy stainless steel pipes, one big choice is the wall thickness. Some pipes have thin walls, others have thick ones. This choice affects strength, weight, cost, and how well the pipe works in your project. In this article, we compare thin-wall and thick-wall stainless steel pipes. We look at what each type means, their good and bad points, where to use them, and how to pick the right one. This guide helps you make a smart decision for industrial, building, or other uses.

What Does Wall Thickness Mean?

Wall thickness is the measurement of the pipe’s wall from the inside to the outside. It is shown in inches or millimeters. For example, a pipe might have a 0.065-inch wall or a 0.250-inch wall.

Thin-wall pipes usually have walls less than 0.120 inches thick. Thick-wall pipes have walls thicker than that, often 0.188 inches or more.

The wall thickness links to something called “schedule.” Schedule 5 and 10 are thin. Schedule 40 is medium. Schedule 80, 160, and XXS are thick.

The outer diameter stays about the same, but changing the wall changes the inner diameter and how much weight the pipe can hold.

Thinner walls mean more space inside for flow. Thicker walls mean less inside space but much more strength.

Advantages of Thin Wall Stainless Steel Pipes

Thin wall pipes have clear benefits in many situations.

First, they weigh less. A thinner wall uses less steel, so the pipe is lighter. This makes shipping cheaper and easier to handle during install.

They cost less per foot. Less material means lower price. For big projects with long runs, this saves a lot of money.

Thin walls give better flow. The inside diameter is larger for the same outer size. Fluids or gases move faster with less resistance. This is good for water systems or air lines.

They are easier to bend and shape. You can curve them without special heavy tools. This helps in tight spaces or when you need custom layouts.

Thin wall pipes work well in low to medium pressure jobs. They handle normal use without problems.

They look clean and modern. The slim profile fits well in visible areas like handrails or furniture frames.

For heat transfer, thin walls let heat move through faster. This is useful in heat exchangers.

Overall, thin wall pipes are practical when weight, cost, and flow matter most.

Disadvantages of Thin Wall Stainless Steel Pipes

Thin wall pipes are not right for every job.

They cannot take high pressure. Under too much pressure, the wall might bulge or burst. This makes them unsafe for high-pressure gas or oil lines.

They dent or bend more easily. A hit from tools or heavy items can damage them.

Corrosion hits them harder in some ways. If rust starts, it eats through the thin wall faster than a thick one.

They are not as strong against bending or twisting forces. In structures that shake or move, they might fail sooner.

For very hot or cold conditions, thin walls can warp more from temperature changes.

You need careful handling during install to avoid dents.

In short, thin walls trade strength for lightness and savings.

Advantages of Thick Wall Stainless Steel Pipes

Thick wall pipes shine when strength is the top need.

They handle high pressure very well. The extra material lets them take big loads without failing. This is key for steam lines, hydraulic systems, or deep oil wells.

They resist damage better. Dents, scratches, or impacts do not hurt them as much. This is good in rough places like factories or construction sites.

Thick walls last longer in harsh spots. Corrosion takes longer to go through the material. They also stand up to abrasion from solids in the flow.

They provide more structural support. You can use them as load-bearing parts in frames or supports.

In high-temperature uses, thick walls hold shape better and resist cracking.

They meet strict safety codes in many industries. Some rules require thick walls for certain pressures or fluids.

Thick wall pipes give peace of mind in critical systems where failure is not an option.

Disadvantages of Thick Wall Stainless Steel Pipes

Thick wall pipes come with some downsides too.

They cost more. More steel means higher price per foot. For long runs, the total cost goes up fast.

They are heavier. This makes transport and install harder. You might need cranes or more workers.

The inside diameter is smaller for the same outer size. This reduces flow rate. You might need a larger outer pipe to get the same flow, which adds even more cost and weight.

Bending them is tough. You need strong machines, and tight bends can cause issues.

They use more material, so they are less eco-friendly in terms of resource use.

In low-pressure jobs, the extra strength is wasted. You pay for features you do not need.

These points show thick walls are best only when you really need the added power.

How to Choose Between Thin and Thick Wall Pipes

Picking the right wall thickness starts with your project details.

First, check the pressure. Look at the max pressure your system will see. Use pipe charts or talk to engineers to see if thin walls can handle it. If pressure is high, go thick.

Next, think about the fluid. Is it just water? Thin might work. Is it high-pressure steam or chemicals? Thick is safer.

Consider the environment. In corrosive areas like near the ocean, thicker walls give longer life. In clean indoor settings, thin walls save money.

Look at flow needs. If you need high flow, thin walls help by keeping the inside bigger.

Check weight and space. If the pipes go in tight spots or high up, lighter thin walls are easier.

Budget is important. Compare total cost, not just price per pipe. Include installation, support needs, and future repairs.

See industry standards. Some fields, like pharma or food, need certain thicknesses for hygiene or safety.

Talk to suppliers. They know what works best for similar jobs. For example, if you need thin options, check out this thin wall stainless steel tube selection.

Test or get samples if you can. See how they fit your setup.

For many projects, a mix works best. Use thick in high-stress parts and thin elsewhere.

Make a simple list: pressure, flow, environment, cost. Rank what matters most. This leads to the smart choice.

Conclusion

Thin-wall and thick-wall stainless steel pipes each have their place. Thin walls save weight, cost, and give better flow for lighter duties. Thick walls bring strength, safety, and long life for heavy or risky jobs. Understand your needs first—pressure, flow, environment, and budget. Then pick the thickness that matches. The right choice keeps your system safe, efficient, and cost-effective. If you want help finding the best pipes, visit https://www.hnyasco.com/ for a full range of options. Good planning now means fewer problems later.