The manufacturing industry frequently uses plastic molding methods, which include overmolding and insert molding. Both manufacturing methods unite different components to develop powerful operational pieces. The medical sector, automotive industry, consumer sector, and electronics industry make use of these methods.

The two processes share common characteristics yet how they function differs substantially. Knowledge of their attributes will help you select the most appropriate approach. Each method will be explained before we examine their distinctions.

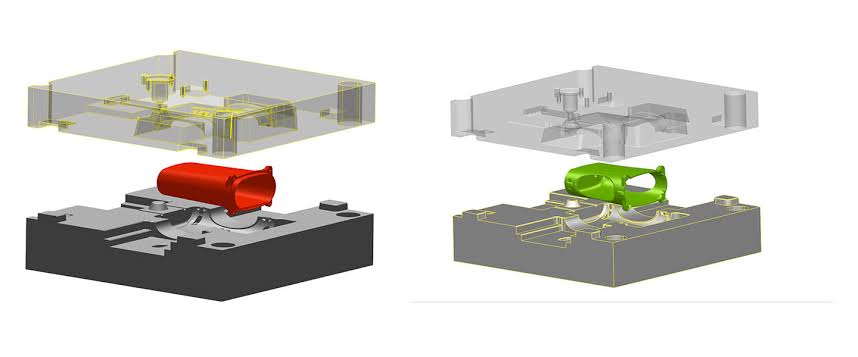

What is Insert Molding?

Through insert molding technicians embed a metal or plastic component inside a mold to which they inject plastic material. After molding the part enters the process the plastic material is supplied for encasement of the piece. The product receives its new permanent element from the insertion phase in the production process, read more.

Through this technology, the insert seamlessly unites with plastic material to form a robust connection. The process eliminates the requirement of welding and assembling as supplemental operations.

Common Inserts:

- Screws

- Electrical contacts

- Bushings

- Blades

Where It’s Used:

- Medical tools

- Electronic devices

- Automotive switches

- Plastic knobs with metal cores

What is Overmolding?

A material undergoes overmolding by being encapsulated into a mold containing another material. The first production step creates the base component, which professionals like GBM Insert Molding Service also term substrate. The process requires forming a second material layer on top of the first.

This creates a layered product. The two bonded components require no added adhesive or mechanical connectors for their connection.

Common Uses:

- Toothbrush handles

- Tool grips

- Phone cases

- Buttons with soft-touch surfaces

Materials Used:

- Thermoplastics

- Rubber-like plastics

- Hard plastics for cores

Comparison of Fundamental Factors Between Insert Molding and Overmolding

The production methods require combining materials, yet their operational purposes remain different.

1. Process

Mold insert manufacturing occurs when production personnel place an existing insert inside the mold. Plastic is injected around it.

The core molding process starts with forming the base part. A second layer is applied directly on the previous material.

2. Materials

Metal joins plastic through an insert molding process.

The combination of two plastic materials or plastic covering metal occurs during the overmolding process.

3. Purpose

Insert Molding finds application when securing parts including fasteners or contacts.

The manufacturing process of overmolding combines two steps to produce parts with enhanced grip qualities and colored finishing and increased product comfort.

4. Number of Steps

Manufacturing through insert molding happens in one single step within the molding machine.

Overmolding: Requires two molding steps.

5. Bonding

A mechanical bond develops all around the insert during the insert molding process.

Overmolding: Depends on heat and pressure to fuse layers.

Pros of Insert Molding

- Reduces assembly time

- Creates durable parts

- Ideal for electrical and mechanical components

- Saves space inside products

- Improves part strength

Pros of Overmolding

- Improves grip and feel

- Adds color or branding

- Protects base parts from damage

- Reduces vibration or noise

- Combines hard and soft features

Typical areas that utilize both methods

- Automotive

- Electronics

- Medical

- Consumer products

- Aerospace

Which One Should You Use?

Your product needs influence which solution will work best.

Choose insert molding when:

You must achieve a strong connection between plastic elements and metal components.

The component demands attachments that incorporate fasteners together with wires.

Molding procedures after assembly creation will decrease significantly.

Choose overmolding when:

Do you want a soft grip or feel

Protection mechanisms or insulation measures are necessary for this product.

Your objective is paint-free color addition.

Cost and Design Considerations

A normal requirement for insert molding is the usage of specific dedicated inserts. Extra setup processes and expenses become necessary because of this method. The part production process benefits from decreased assembly requirements because of this method.

The manufacturing process of overmolding performs two distinct operations which increases its production duration. Better comfort, grip and the improved style are achieved through this process. The method protects bases against both physical impacts and moisture penetration.

Design stands as the crucial factor for both insert and overmolding techniques. The design of the mold must align all components appropriately.

Advantages of Insert Molding

- Strong bond between metal and plastic

- Good for high-stress applications

- Saves space in small devices

- Reduces number of loose parts

Advantages of Overmolding

- Smooth finish and better feel

- Shock and impact resistance

- Easy to hold and use

Limitations

Insert Molding:

- Inserts must be made first

- The cost of establishing operations increases when manufacturing small quantities of products.

Overmolding:

- Longer production time

- May need special machines

Conclusion

Both insert molding and overmolding serve as intelligent approaches that unite different materials in one operation. These processes enhance both the mechanical strength as well as the operational functionality and aesthetic quality of parts. A single operation using insert molding allows the combination of plastic with metal components. Requirements demanding comfort together with style and protection suggest overmolding as the preferred approach.

Understanding these distinctions lets you select an appropriate process. Each approach to manufacturing brings independent advantages to the process. The selection depends on how the part serves, what it looks like, and the required materials.