Introduction to Welding Tables

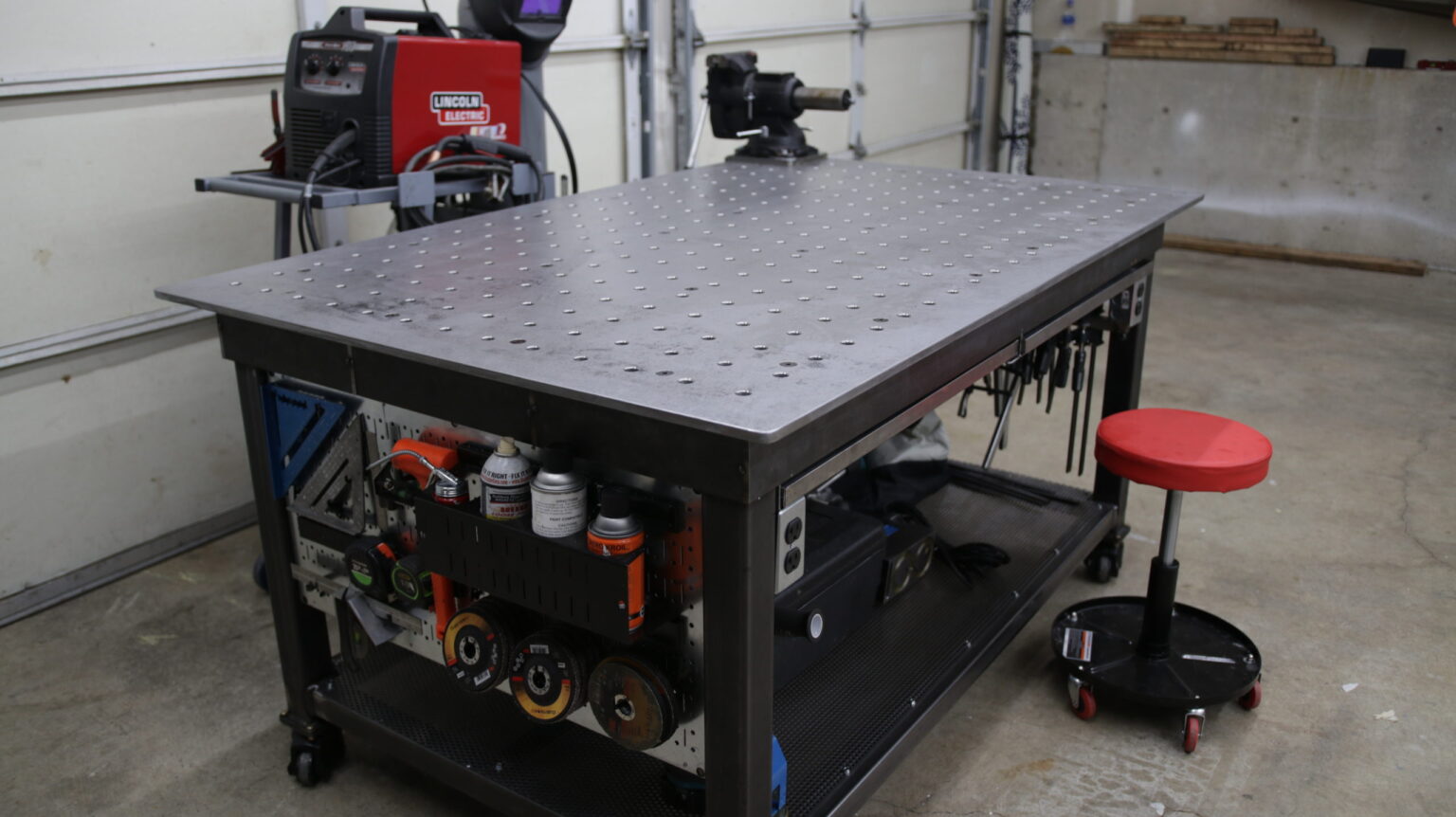

Welding is a fascinating craft that combines skill, precision, and creativity. At the heart of this process lies one essential tool: the welding table. Whether you’re a seasoned professional or an enthusiastic DIYer, having the right welding table can make all the difference in your projects. It provides stability, support, and organization while allowing you to focus on what really matters—bringing your ideas to life.

In this comprehensive guide to welding tables, we’ll explore various types available on the market today, weighing their pros and cons so you can find your perfect match. We will also discuss key factors to consider when choosing a table tailored for your needs. Plus, we’ll provide tips for setting up efficiently and maintaining safety throughout your work sessions.

Whether you’re looking for inspiration with DIY projects or need some practical advice on using these tables effectively, we’ve got you covered! Let’s dive into everything there is to know about welding tables—the backbone of any successful project.

Types of Welding Tables: Pros and Cons

Welding tables come in various types, each catering to different needs.

Steel welding tables are robust and offer excellent durability. They handle heavy materials well but can be quite heavy themselves, making them less portable.

Aluminum options are lighter and easier to move around. However, they may not withstand the same level of heat as their steel counterparts.

Modular welding tables provide flexibility with adjustable components. You can customize your setup for specific projects, but they often come at a higher price point.

There are collapsible or foldable tables designed for those with limited space. While convenient for storage, these might lack stability under heavier loads compared to fixed options.

Choosing the right type depends on your workspace and project requirements.

Factors to Consider When Choosing a Welding Table

When selecting a welding table, size plays a crucial role. Consider the space you have available and the types of projects you’ll undertake. A larger surface area allows for more flexibility but may not fit in smaller workshops.

Material is another important factor. Steel tables are durable and can withstand high temperatures, while aluminum options are lightweight and easier to move.

Weight capacity must also be assessed. Ensure the table can support your heaviest workpieces without compromising stability or safety.

Adjustability matters too—some tables offer height adjustment features that cater to various tasks and user comfort.

Think about additional features such as clamping systems or built-in storage solutions that enhance functionality and organization during your welding projects.

How to Set Up and Use a Welding Table

Setting up your welding table begins with selecting the right location. Choose a well-ventilated area that is free from flammable materials. A stable, level surface will help ensure precision during your projects.

Next, secure any necessary tools and equipment nearby. Keep essential items like clamps and safety gear within arm’s reach to streamline your workflow.

Adjust the height of the table if possible, ensuring it suits your comfort level while working. This reduces strain on your back and promotes better control over your welds.

When using the table, always wear appropriate protective gear—gloves, helmet, and long sleeves are a must. Secure workpieces firmly before starting any welding process to maintain stability.

Remember to keep a fire extinguisher close by as an added precaution against potential hazards while you craft unique metal creations on your welding table.

Maintenance and Safety Tips for Welding Tables

Regular maintenance of your welding table is essential for safety and efficiency. Start by keeping the surface clean from slag, spatter, and debris. This not only helps in maintaining a smooth working area but also reduces fire hazards.

Inspect your table for any signs of wear or damage. Look for cracks or rust that could compromise its structural integrity. Prompt repairs can prolong the life of your equipment.

Properly securing workpieces is crucial. Use clamps or fixtures to stabilize materials during welding to prevent movement that could lead to accidents.

Always ensure adequate ventilation while using a welding table. Fumes generated during the process can be harmful if inhaled over time.

Using personal protective equipment (PPE) like gloves, goggles, and aprons cannot be overstated. They protect against sparks and potential injuries associated with metalwork tasks.

Keep a fire extinguisher nearby as part of your safety protocol when operating in environments where flammable materials are present.

DIY Projects Using a Welding Table

Welding tables are versatile tools that open the door to countless DIY projects. From simple repairs to complex fabrications, they provide a solid foundation for creativity.

One exciting project is building custom furniture. Consider crafting a unique coffee table or even outdoor seating. With precise measurements and sturdy materials, you can create pieces that perfectly fit your space.

Another engaging idea is constructing decorative metal art. Use scrap metal to design sculptures or wall hangings that showcase your style. This not only utilizes leftover materials but also adds personality to your home.

For those interested in practical applications, think about creating tool racks or storage solutions. Organizing your workspace helps keep everything within reach while adding an industrial aesthetic.

Try making brackets or frames for various installations around the house. These small yet essential items often require precision welding and can enhance functionality throughout your living space.

Conclusion

Selecting the right welding table can make a significant difference in your projects. It enhances precision and efficiency, allowing for smoother workflows.

Whether you opt for a fixed or adjustable model, understanding its features is crucial. The stability it provides directly impacts the quality of your welds.

Moreover, incorporating maintenance practices ensures longevity and safety. Proper care keeps your workspace organized and minimizes hazards.

Engaging with DIY projects on your welding table opens up creative possibilities. Experimentation breeds innovation, making each session enjoyable and productive.

Embrace the unique characteristics of different tables to find what suits you best. With thoughtful consideration, you’ll forge ahead in both skill and craftsmanship.

FAQs

Welding tables are essential tools for both hobbyists and professionals. If you’re considering investing in one, you probably have some questions. Here are answers to the most common queries about welding tables.

Q: What is a welding table used for?

A: A welding table provides a stable surface for various metalworking tasks. It supports workpieces during cutting, grinding, and assembly, ensuring precision and safety.

Q: How do I choose the right size of a welding table?

A: The ideal size depends on your workspace and projects. Larger tables offer more flexibility but require ample space. Consider your typical project dimensions when selecting.

Q: Are there portable options available?

A: Yes! Portable welding tables are lightweight and easy to move. They’re perfect if you need flexibility or lack dedicated workshop space.

Q: Can I build my own welded table?

A: Absolutely! Many DIY enthusiasts create custom tables suited to their needs using scrap metal or other materials. Just ensure it’s sturdy enough to handle heavy workloads.

Q: What materials should my welding table be made from?

A: Steel is the most common material due to its strength and durability. However, aluminum can also be an option if weight is a concern.

Q: Do I need additional accessories with my welding table?

A: Accessories like clamps, vices, or magnetic squares can enhance functionality by providing better support while working on projects.

Keeping these FAQs in mind can help streamline your decision-making process regarding welding tables. Whether you’re setting up a home workshop or improving efficiency at a professional shop, proper knowledge makes all the difference.