Cutting hard materials has always been a challenge in industries ranging from semiconductors and aerospace to ceramics and advanced composites. Traditional cutting tools often struggle to deliver the precision, speed, and surface finish required for high-end applications. Enter endless diamond wire cutting—a game-changing technology designed to transform how hard materials are processed. At the forefront of this innovation is the ESG400 Diamond Wire Loop Saw Cutting Machine, engineered to provide unmatched performance and accuracy.

What is Endless Diamond Wire Cutting?

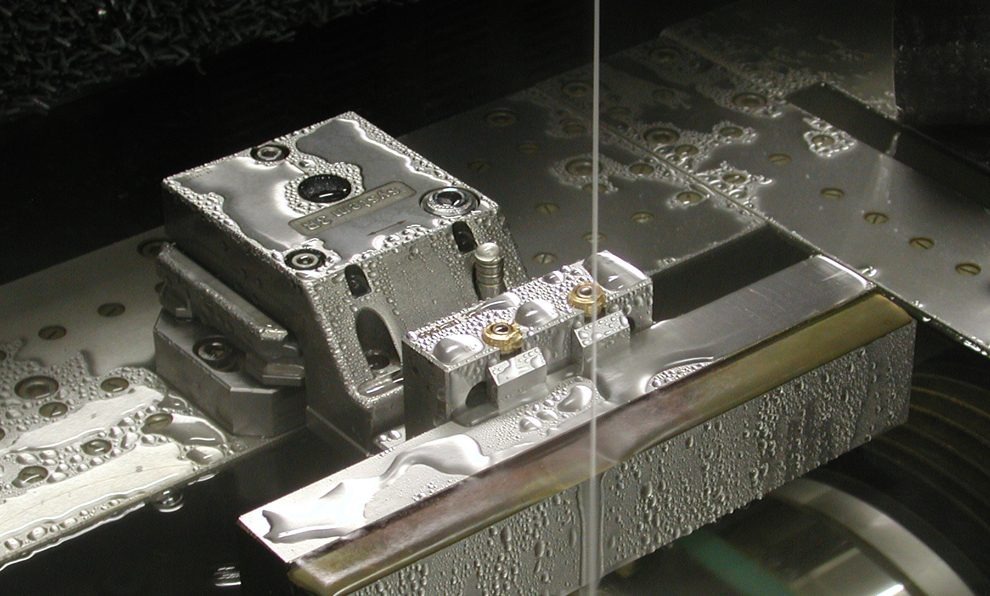

Endless diamond wire cutting utilizes a looped wire impregnated with industrial-grade diamond abrasives. Unlike conventional saws that use straight wires or blades, the wire in this system forms a continuous loop, allowing for consistent and uninterrupted cutting. This not only improves the cutting speed and surface quality but also reduces wear and tear on the equipment.

The principle is simple yet effective: the diamond wire loop runs over a system of pulleys at high speed, and as it comes into contact with the material, it slices through it with precision and minimal force. This method is especially effective for hard, brittle materials like silicon, sapphire, quartz, ceramics, and certain metals that are notoriously difficult to machine using traditional methods.

Why is It Perfect for Hard Materials?

When it comes to cutting hard materials, the main challenges are:

- High tool wear

- Excessive heat generation

- Poor surface quality

- Microcracks and mechanical stress

Endless diamond wire cutting addresses all of these problems. The diamond abrasives provide a clean, sharp cut without introducing significant thermal or mechanical stress. Since the cutting is performed through abrasion rather than sheer force, the material’s structural integrity remains intact.

Moreover, the looped design allows the wire to self-clean as it rotates, preventing clogging and maintaining consistent cutting efficiency. This results in smoother finishes, narrower kerf widths, and reduced material waste—key benefits for high-precision industries.

Introducing the ESG400 Diamond Wire Loop Saw Cutting Machine

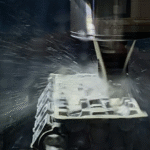

One of the most advanced systems employing this technology is the ESG400 Diamond Wire Loop Saw Cutting Machine. This machine is built specifically to take full advantage of the endless diamond wire cutting method and bring it to industrial-scale operations.

Key Features of the ESG400:

- High Precision Cutting

The ESG400 offers micron-level accuracy, making it ideal for intricate components in electronics, aerospace, and medical devices. Its programmable logic controller (PLC) and user-friendly interface ensure repeatable precision every time. - Minimal Material Waste

Thanks to its ultra-thin wire design, the ESG400 ensures minimal kerf loss, which is especially beneficial when working with expensive raw materials such as single-crystal silicon or sapphire. - Excellent Surface Finish

The ESG400 produces surfaces with minimal roughness, often eliminating the need for secondary polishing processes. This significantly cuts down on production time and costs. - Versatility

From semiconductors to ceramics, the ESG400 is capable of cutting a wide range of hard and brittle materials. Its adaptive design allows for easy customization depending on the project’s requirements. - Enhanced Durability and Efficiency

The ESG400 is built with industrial-grade components, ensuring long service life and high operational uptime. The wire tensioning and guiding systems are optimized for continuous, high-speed cutting without compromising on accuracy.

Applications Across Industries

The ESG400 Diamond Wire Loop Saw Cutting Machine is not limited to a single industry. Its application is widespread:

- Semiconductor Industry: For slicing silicon wafers and substrates with minimal damage.

- Aerospace: Cutting composite materials and titanium alloys with high dimensional stability.

- Medical Devices: Precision cutting of ceramics and bio-compatible metals.

- Optics: Clean, chip-free cutting of quartz and sapphire lenses.

- Renewable Energy: Cutting of photovoltaic cells and silicon blocks for solar panels.

Environmentally Friendly and Cost-Effective

Endless diamond wire cutting is not only efficient but also environmentally responsible. It consumes less power compared to traditional cutting tools and produces fewer particulates and waste. The ESG400 Diamond Wire Loop Saw Cutting Machine further enhances this with its energy-efficient motors and optimized wire usage, making it a cost-effective and sustainable solution for modern manufacturing needs.

Conclusion

For companies and industries seeking precision, speed, and reliability in cutting hard materials, endless diamond wire cutting is the ideal solution. And when it comes to the most effective implementation of this technology, the ESG400 Diamond Wire Loop Saw Cutting Machine stands out as a top-tier choice. Its unmatched precision, adaptability, and efficiency make it a must-have for any high-performance production environment.

Whether you’re working with fragile ceramics or tough industrial metals, the ESG400 ensures your cutting process is clean, fast, and flawless—redefining what’s possible in hard material machining.