Solar farms have become at the centre of discussion in areas of renewable energy because of the growing interest in renewable energy. But the process of getting a plot of land up and running as a full scale solar farm is not an easy one and depends on technical accuracy, long term planning and sound infrastructure. In case you have always asked a question on how to construct a solar farm in pieces, the guide to the full process has been provided, starting with the selection of a territory and ending with the optimization of a system in the long term. In it, quality industrial electrical equipment is an important factor in the determination of efficiency, safety and reliability of the energy system.

Site Selection and Pre-Planning

The location of a solar farm is the initial minor process in constructing a solar farm. The land that has been selected should have consistent sunlight all throughout the year, be level or sloping on a low level and should have easy access when it comes to installation and maintenance. You should also evaluate other environmental conditions like the type of soil, drainage and shading that might be caused by trees or buildings or whatever. Zoning and other local regulations require early check up to eliminate the legal issues. Once you have determined the location, you will be required to obtain required permits, carry out environmental assessments, and determine the arrangement of grid connection. The planning stage of this phase also involves estimating the generation figure, determining the system capacity and developing a comprehensive financial model involving capital cost, cost of operations, estimated returns and many others as an estimate. At this stage, most developers collaborate with suppliers of industrial electrical equipment with the aim of anticipating technical equipment requirements and building a supply chain of transformers, inverters, and protective components suitable for large-scale solar.

Component Specification System Design

Engineering of the electrical and structural layout of a solar farm is very tricky. The choice of solar panel type i.e., monocrystalline, polycrystalline and thin film determines the efficiency, the cost, and space occupied. The best use of panel orientation, tilt angle and row spacing are done according to the latitude of the site and weather conditions so they maximize energy capture. Electrical wiring is also very important. The size of string, location of inverter, grounding, routing of wires are some aspects that engineers need to determine. Inverters are important to convert DC power in the panel to usable AC power. Effective choice of inverter type and size (central or strings) has an influence on total efficiency and monitoring of the system. Infrastructure support also needs to be taken into consideration like racking systems and weather resistant cabling. The use of reliable and compliant hardware with the codes with industrial electrical supply partners that can deliver can mean the solar farm lasts long and can still operate reliably regardless of weather. Their experience plays a key role in procurement of compatible surge protection gadgets, disconnect switches and combiner boxes complying with the national standards.

Installation and Electrical Integration

Having the plans and materials in place, it is now time to physically install. They involve preparation of the site to remove vegetation, raking the ground and cutting access roads where necessary. The systems which are erected on the ground, mounting systems are finally erected on the ground and then solar modules are placed and linked. The cabling operation is a connection of solar panels to the inverters and finally to the principle transformer. It is also important at this point that voltage drop should be handled as well as electrical losses should be avoided by careful engineering. There must be the incorporation of protective mechanisms like the breakers, fuses and surge protection equipment to protect against faults and lightning strikes. Another measure that you cannot compromise on safety-wise is proper grounding. Then electricity is fed into a main transformer that goes up in voltage to be compatible with the grid by the inverter. Final testing and inspections are carried out, and after being satisfactory, utility interconnection is installed. Working in cooperation with a specialized industrial electrical equipment supply company at this point will guarantee that there will be a source of certified hardware and technical assistance that is responsive during the most crucial phase of construction.

Regulatory Compliance And Safety Systems

As soon as the tangible infrastructure is ready, the emphasis is on introducing the safety systems and passing the regulating inspection. Solar farms have to be electrically safe as well as fire safe according to regional standards. This entails application of circuit breakers that are rated well, disconnects, labeling, and availability of emergency shutdown systems. Lightning can be a big threat to sensitive electronics, which could use a voltage spike due to a lightning strike. Surge protective devices are necessary to help protect the sensitive electronic equipment. Safety is further augmented by the use of isolation transformers and arc-fault protection of both the equipment and the personnel. Local inspection guarantees national electrical codes, renewable energy incentive, and utility interconnection requirements. As-built plans and documentation are to be given the final approval. The liability effect of an incomplete solar farm is that such a farm may even fail to obtain the insurance cover or the grid access it needs. A good quality industrial electrical equipment supply partner assists in this process by providing products that are UL, IEC or TUV certified, advice on how products work with each other (compatibility) and how to install them safely.

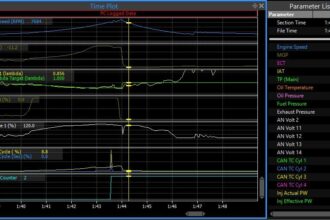

Optimization, Monitoring and Maintenance

After the operation, monitoring and continuous maintenance becomes vital in maximizing energy production and the returns on investments. The use of SCADA (Supervisory Control and Data Acquisition) system lets you observe the voltage level, the work of panels, the work of inverters, and the efficiency of the whole system in real-time. Modules that are performing poorly or malfunctioning connections can be identified early enough to avoid major breakdown of the system and subsequent loss of revenue. Cleaning of the panels, weed control, and continuous check up ensure maximum energy production. Besides, the integration of energy storage, e.g., battery systems, may stabilize the power supply within the grid fluctuations or in the situation of increased demand. The implementation of predictive analytics and AI-based diagnostics enables predicting problems in advance and eliminating downtime before they get any worse. Understanding how to build a solar farm step by step and maintain it involves not just physical infrastructure, but also digital tools that improve operational reliability. Combined with a trusted supply of industrial electrical equipment in your electrical equipment supply chain, this wholesome strategy keeps your solar farm efficient, safe and expandable even beyond decades.