Introduction

In the world of rapid tooling and high-speed production, unexpected mold downtime is a major cost driver. Problems often stem from the failure of internal precision turned parts (such as ejector pins and inserts) to meet specifications for accuracy, surface finish, or material properties, rather than from the mold base material itself. By deeply integrating mold design philosophy with professional CNC turning services to customize high-precision metal components, it is possible to fundamentally enhance mold reliability and ensure a seamless transition from prototype moulding to mass production.

Why Does Overall Mold Reliability Far Exceed Cavity Design Alone?

A successful injection mold is a complex system engineering project. Its reliability depends on hundreds of components working in concert, with the overall performance constrained by the weakest link. Well-designed aluminium moulds often experience premature failure during high-frequency rapid tooling cycles not because of the cavities, but due to seemingly insignificant turned parts. Examples include bent ejector pins causing product scratches, wear on guide pillars/pins affecting clamping accuracy, and seal failure in cooling water connectors leading to leaks and production stoppages. Therefore, selecting a turned parts supplier that can provide high precision, excellent consistency, and has a deep understanding of harsh mold operating conditions is of strategic significance for ensuring long-term, stable mold operation.

H2:How Does Design for Manufacturability Optimize the Performance of Turned Parts?

Systematically applying DFM (Design for Manufacturability) principles early in the mold design phase is crucial for the performance of internal turned parts. An excellent DFM process establishes scientifically sound tolerance bands, surface roughness requirements, and optimizes the geometry of these critical functional components. For instance, avoiding sharp corners and incorporating appropriate fillets effectively reduces stress concentration, significantly enhancing the wear resistance and fatigue strength of the parts under long-term, high-speed, high-pressure cyclic loading.

Collaborating with experienced brass precision turned components manufacturers at the project’s outset can yield invaluable DFM advice. They can provide guidance on design optimization based on the intrinsic properties of materials and specific processing capabilities, improving quality and controlling costs at the source.

The table below outlines key DFM considerations:

| DFM Optimization Dimension | Potential Consequences of Poor Design | Core Benefits After DFM Optimization |

|---|---|---|

| Tolerance Design | Loose Tolerances: Cause excessive clearance between mating parts, leading to wobble and accelerated wear. Overly Strict Tolerances: Unnecessarily drive up machining costs in non-critical areas. | Setting the most economical tolerances based on actual functional requirements ensures precise fit while maximizing cost-effectiveness. |

| Surface Finish | High Surface Roughness: Increases the coefficient of friction, leading to easier wear and generation of debris that can contaminate the mold cavity and final product. | Specifying appropriate Ra values (e.g., mirror polishing for sealing surfaces) effectively reduces friction resistance and extends component service life. |

| Geometric Optimization | Presence of Sharp Corners or Edges: Creates stress concentration points, making it easy for cracks to initiate under alternating loads, leading to part fracture. | Using smooth fillet transitions distributes stress more evenly, thereby significantly increasing the fatigue strength and overall reliability of the component. |

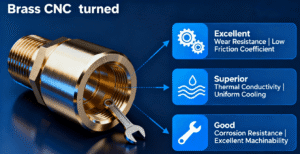

Figure 2: Brass CNC turned components, like this nozzle, offer a unique combination of properties critical for demanding mold applications, directly impacting longevity and performance.

Why is Brass an Ideal Material for Precision Mold Components?

Among the many engineering material options, brass stands out as an ideal choice for manufacturing precision mold components due to its unique combination of properties, particularly excelling in applications demanding high wear resistance, excellent thermal conductivity, and corrosion resistance.

Excellent Physical Properties Meet Demanding Mold Conditions

Brass exhibits outstanding physical characteristics in precision mold applications, allowing it to perfectly adapt to the complex internal environment of molds.

- Superior Mechanical Properties and Wear Resistance

Brass naturally possesses good lubricity and a low coefficient of friction, making it highly suitable for manufacturing frequently moving mold parts like ejector pins, bushings, and guide sleeves. Its inherent excellent wear resistance translates directly into longer service life and reduced maintenance downtime. According to recommendations from the American Plastics Industry Association for mold standard parts, selecting the right material is key to extending mold life.

- Excellent Thermal Conductivity and Dimensional Stability

Components precision-machined from CNC machine brass, such as inserts in hot runner systems or elements in cooling systems, can efficiently conduct heat. This helps achieve a uniform temperature distribution across the mold cavity surface, thereby improving the cooling efficiency of the injection molded part, reducing deformation, and enhancing dimensional stability. The British Manufacturing Technologies Association notes that material thermal conductivity directly impacts mold thermal management efficiency.

Outstanding Chemical Stability and Processability

In addition to excellent physical properties, brass also performs exceptionally well in terms of chemical stability and machinability, providing a strong foundation for its use in precision mold manufacturing.

- Significant Corrosion Resistance

Brass resists corrosion well from cooling water and other chemicals, ensuring the mold’s water channel system remains unobstructed long-term. This characteristic ensures stable long-term operation of the mold in humid environments or with special cooling media, greatly extending the mold’s service life. For mold inserts with stringent requirements for wear resistance and thermal conductivity, brass CNC turned parts produced by professional manufacturers are often one of the most ideal solutions.

- Excellent Machinability

The superb machinability of brass allows for the creation of complex shapes and components with extremely tight tolerances through high-precision CNC turning services, such as inserts with fine threads or intricately designed stepped shafts. This good processability not only improves production efficiency but also ensures the dimensional accuracy and surface quality of the parts.

How Does Precision Turning Directly Affect the Final Quality of Molded Parts?

There is a clear and direct causal chain between precision turned parts and the final quality of injection molded parts: the accuracy of the turned parts determines the precision and stability of mold movement, which in turn determines the quality of the injection molding process.

Dimensional Accuracy is the Foundation of Quality

The dimensional accuracy achieved by precision turning is fundamental to ensuring that molded parts meet design requirements, directly impacting the product’s appearance, assembly, and function.

- Dimensional Errors in Key Components and Part Defects

Minute errors in the length of an ejector pin head or its step can cause it to retract micrometers during the injection holding phase, leading to unacceptable flash on the plastic part. Similarly, insufficient accuracy in threaded inserts used in the mold can cause demolding difficulties or assembly issues later, affecting product functionality and reliability.

- Quality Foundation in the Prototyping Phase

Especially during the prototype moulding stage, using high-quality brass turning services to precisely manufacture metal functional components within the mold allows for the assembly of fully functional test units. This provides the most authentic and reliable data support for design verification, avoiding misjudgments caused by inaccurate prototype parts.

Functional Performance Determines Production Stability

Beyond dimensional accuracy, the functional performance of turned parts is directly related to mold production efficiency and the stability of the injection molding process.

- Critical Impact of Sealing Performance on Production Efficiency

The accuracy and finish of the conical sealing surface on a cooling water nozzle, manufactured by professional brass turning services, directly determine sealing reliability. A tiny leak point can lead to loss of mold temperature control, causing product defects and unplanned production interruptions, resulting in significant cost losses.

How to Evaluate a Turning Supplier’s Expertise in Molds?

When selecting a turned parts supplier for critical mold projects, the evaluation criteria must go beyond conventional machining accuracy. Focus should be placed on the supplier’s depth of understanding of mold operating conditions, material expertise, and quality control system.

Industry Knowledge and Engineering Experience are Core

An excellent manufacturer of turned parts needs a deep understanding of the cyclic fatigue loads on mold ejector pins, the high-speed wear mechanisms of guide pillars, and the complex thermal stress issues at hot runner interfaces. This professional expertise enables them to provide more targeted material selection and process optimization advice.

International Certifications are Powerful Proof of Process Control

A supplier holding multiple certifications such as IATF 16949 (automotive), AS9100D (aerospace), and ISO 13485 (medical devices) demonstrates that its quality management system fully meets the requirements for top-tier CNC machining for moulds. These certifications ensure full traceability and quality consistency from raw material procurement through production to final inspection.

CNC Turning Service Capability is a Key Support

For a supplier with comprehensive processing capabilities, the level of their CNC turning service is the foundation for ensuring the quality of complex mold components. Superior CNC turning service capability means the ability to consistently deliver high-precision, high-consistency key parts, which is a vital reflection of mold expertise.

Conclusion

In summary, ensuring the high reliability of injection molds, especially aluminium moulds used in rapid tooling environments, is a systems engineering task involving everything from macro design to micro execution. Its success depends not only on innovative mold design but also on the relentless pursuit of excellence and specialized manufacturing of the numerous internal precision turned parts. These seemingly small components are, in fact, the “joints” and “bloodlines” of the mold; their performance directly determines the lifespan, stability, and final output quality of the entire production system.

Do not let key turned parts become a potential weakness in your mold project. It is recommended to immediately contact JS Precision precision turning solution providers that possess high-end international certifications (such as IATF 16949, AS9100D) and rich experience in the mold industry. Procure durable, high-performance key components for your next mold set to ensure smooth production and product excellence at the root level.

Author Biography

This article was written by an expert with over a decade of experience cultivate in the precision manufacturing field. Through in-depth analysis of hundreds of industrial cases, the expert has unique insights into typical failure modes caused by turned parts, such as ejector pin jamming, insert wear, and cooling system leaks. The expert believes that deeply integrating systematic mold design concepts (like DFM) with high-level CNC turning services capabilities is key to enhancing mold reliability and achieving a smooth transition from prototype moulding to mass production.

FAQs

Q1: What materials are commonly used for precision turned parts in molds?

A1: In addition to brass, tool steel (for components requiring high wear resistance, like core inserts), stainless steel (for corrosion-resistant parts like cooling water nozzles), and high-strength aluminum alloy (for lightweight mold structural components) are also very common. The final material selection depends on the component’s specific function, load conditions, wear environment, and thermal load within the mold.

Q2: What are the typical tolerance requirements for precision turned parts used in molds?

A2: For key mating components in molds, such as guide pillars, ejector pins, and sleeves, the diameter tolerance is usually required to be controlled within ±0.01 mm or even stricter. This requires the supplier to be equipped with high-performance machining equipment for both CNC machine brass and steel, and to implement strict quality control processes.

Q3: How can precision turned parts help improve mold cooling efficiency?

A3: Precision turning technology can manufacture specially shaped cooling water nozzles, baffles, or bubblers with precisely controlled wall thicknesses. These components optimize the connection of cooling channels and the distribution of the internal flow field, enabling uniform and efficient mold cooling, thereby shortening the injection cycle and reducing product deformation.

Q4: What is the typical lead time for custom, non-standard turned mold parts?

A4: Standard parts may be available from stock with professional turned parts suppliers. The lead time for non-standard custom parts usually depends on the complexity and quantity of the components. However, to support the pace of efficient rapid tooling projects, many specialized suppliers can complete production and inspection of most conventional custom parts within 1 to 2 weeks.

Q5: How can you effectively verify the reliability of a turning supplier’s quality management system?

A5: Prioritize suppliers that can openly and transparently display their international certification credentials, such as ISO 9001, IATF 16949, AS9100D, ISO 13485, etc. These certifications are internationally recognized evidence of the establishment and operation of a stable and reliable quality assurance system. Additionally, you can request to review the first-article inspection reports or process quality control records for their typical workpieces.